How to create optimal conditions for existence? What pressure should be in the heating system

Pressure standards in the heating system are set accordingly GOST and SNiP, are designed to ensure safe operation of equipment and create comfortable living conditions.

It is advisable to adhere to these standards both in multi-storey buildings and private buildings. On pressure various factors influence, which are taken into account when designing heating.

Content

Determining factors: capacity of expansion tank, type of system, etc.

The pressure in the heating system depends on several factors:

- Equipment power. The static component is determined by the height of the multi-story building or the rise of the expansion tank. The dynamic component is determined to a greater extent by the power of the circulation pump and to a lesser extent by the power of the heating boiler.

- System type: open or closed; single-pipe, double-pipe or manifold; vertical or horizontal.

- Size of pipes and radiators. Determines the volume of the circulating coolant. The pressure decreases with increasing pipeline diameter. When using pipes of different diameters in the main line, a pressure drop appears at their junction.

- Location of the apartment. Ideally, the pressure does not depend on the location of the room. In reality, it depends on the floor and the distance from the boiler or the connection to the riser.

When providing the required pressure in the system, the appearance of obstacles to the movement of the coolant in pipes and radiators is taken into account. With long-term operation, scale, oxides and sediment accumulate in them. This leads to a decrease in diameter, and therefore to an increase in resistance to the movement of liquid. This is especially noticeable with increased hardness (mineralization) of water. To eliminate the problem periodically carry out a thorough flushing of the entire heating structureIn regions where the water is hard, hot water purification filters are installed.

Standardization of working pressure in apartment buildings

Multi-storey buildings are connected to central heating, where the coolant comes from the thermal power plant, or to house boiler houses. In modern heating systems, the indicators are maintained in accordance with GOST and SNiP 41-01-2003. Normal pressure ensures the temperature in the rooms 20—22 °C at humidity 30-45%.

Depending on the number of storeys of the building The following standards have been established:

- in high rise buildings up to 5 floors 2-4 atm;

- in buildings up to 10 floors 4-7 atm;

- in buildings above 10 floors 8-12 atm.

It is important to ensure uniform heating of apartments located on different floors.

The normal condition is considered to be when the difference between the working pressures on the first and last floors of a multi-storey building is no more than 8-10%.

During periods when heating is not needed, the system maintains minimum values. It is determined by the formula 0.1(Hx3+5+3), Where N — number of floors.

In addition to the number of storeys of the building, the value depends on the temperature of the incoming coolant. Minimum values are set: at 130 °C ― 1.7-1.9 atm., at 140 °C ― 2.6-2.8 atm. and at 150 °C ― 3.8 atm.

Attention! An important role in the efficiency of heating is played by periodic checking of performance indicators. They are monitored during the heating season and in the off-season.

During operation, control is carried out according to pressure gauges installed at the inlet and outlet heating schemes. At the input, the amount of incoming coolant must correspond to the established standards.

Check the difference in pressure at the input and output. Normally, the difference is 0.1-0.2 atm. The absence of a difference indicates that there is no water movement to the upper floors. An increase in the difference indicates the presence of coolant leaks.

During the warm season, the heating system is tested using pressure tests. Testing is usually performed with cold water pumped through a pump. Depressurization of the system is recorded when the indicators drop over the course of 25-30 minutes by an amount greater than 0.07 MPa. A fall is considered normal by 0.02 MPa for 1.5-2 hours.

Photo 1. The process of pressure testing the heating system. An electric pump is used, which is connected to the radiator.

What is the optimal pressure in a closed heating system?

Above we have considered the heating of "multi-storey buildings", which is provided by a closed scheme. When arranging a closed system in private houses, there are nuances. Usually, circulation pumps are used, which maintain the required indicators. The main condition for their installation is that the pressure created should not exceed the parameters for which the heating boiler is designed (specified in the equipment instructions).

At the same time, it must ensure the movement of the coolant throughout the system, while the difference in water temperature at the outlet of the boiler and at the return point should not exceed 25—30 °C.

For private, single-story buildings, the pressure in a closed heating system is considered the norm within 1.5-3 atmThe length of the pipeline with gravity flow is limited 30 m, and when using a pump the restriction is removed.

Setting maximum values

Standards for maximum pressure in a heating system are established taking into account the characteristics of the equipment and pipes used.

For example, the following limits apply to radiators: cast iron batteries - up to 6 atm., plastic 2-4 atmThe weak points are considered to be the joints of the heating system elements.

Setting the maximum values is performed in the following sequence:

- System pressure testing. The circuit is filled with water under pressure exceeding the operating value in 2-2.5 timesDuring the pressure test, the change is monitored using a pressure gauge.

- Checking for leaks. Testing is in progress in 2 stages - cold and hot test. At the first stage the system is filled with cold water at minimum operating pressure. It is maintained in this state 2 h. If during this time the indicators have decreased by no more than at 0.2 atm., then we can talk about good tightness. At the second stage the heating boiler is switched on at full power and the main line is filled with hot coolant at maximum working pressure. The change in the parameter is controlled by a pressure gauge.

- Setting the working pressureAfter testing is completed, the excess pressure is released using the valve and the operating value is set.

Testing the system at maximum performance helps to identify problem areas, including leaks. All violations are immediately eliminated. It is impossible to start operating the system without eliminating weak points.

Standards for expansion tank

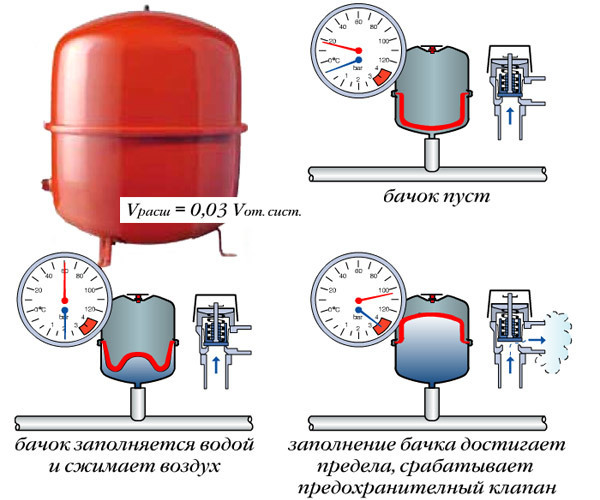

A closed heating system can be based on the use of an expansion tank. In this case, membrane type tankIn an open design, a standard container is used, the pressure in which is provided by the height of its location and the level of liquid in the tank.

Photo 2. Diagram of the membrane expansion tank. Pressure standards for different levels of filling the product with water are indicated.

In a closed design, it is necessary to provide the initial pressure of the chamber. The fact is that the heating boiler simply will not work without creating pressure in the system, the minimum value of which is specified in the instructions for the equipment. For most boiler models, it is 0.7-0.8 atm. Optimal operation is ensured with external indicators 1.1-1.2 atm., it should be taken into account that the membrane itself is capable of increasing it by 0.3-0.4 atm. Taking this into account, in the expansion tank of a closed system it is necessary to ensure an initial pressure in the range 0.7—1 atm.

You can control the volume in the expansion tank using a manual pressure gauge. In the air chamber of the membrane-type tank there is a nipple outlet through which measurements are taken. Constant monitoring is ensured by installing a tire-type pressure gauge in the tank. If the pressure in the air chamber of the tank is insufficient, pumping is performed using a regular air, hand pump with a pressure gauge. If it cannot be raised, then a defect or damage to the membrane should be looked for.

Useful video

Watch a video that explains what the standards should be in a closed heating system.

The Importance of Compliance with Standards for Private Homes and Multi-Story Buildings

Pressure standards in the heating system of a private house or a multi-storey building are established by mandatory, valid documents. These values help to ensure a comfortable temperature in the room. However, their main purpose is ensuring safe operation. Excessive pressure in the system not only disables the equipment, but also becomes dangerous for humans. Hot water circulates in the system, and a pipe break or a breach in the tightness of the joints leads to burns. Taking this into account, it is important to comply with the established norms and rules when installing a heating system.