Ensuring the full operation of the system: choosing the pipe diameter for heating a private house

Heating a house or apartment is not such a simple engineering system as it may seem at first glance. When drawing up a project, it is necessary do a lot of calculations, in particular, the required pipeline diameter.

Choosing the right diameter is the key to a reliable, comfortable and efficient system heating of premises.

For example, heating without a pump, where the coolant circulates by gravity, may not work at all if the pipes are too narrow, and a system with forced circulation if the diameter is too small will make noise or will not heat the room to the required temperature. Therefore, it is necessary to use calculation rules that will allow heat loss to be reduced to a minimum.

Content

The influence of pipe diameter on efficiency for a heating system in a private house

It is a mistake to rely on the principle of "bigger is better" when choosing a pipeline cross-section. Too large a pipe cross-section leads to reduce pressure in it, and therefore the speed of the coolant and heat flow.

Moreover, if the diameter is too large, the pump will simply may not have enough performance to move such a large volume of coolant.

Important! A larger volume of coolant in the system implies a high total heat capacity, which means more time and energy will be spent on heating it, which also affects efficiency in a negative way.

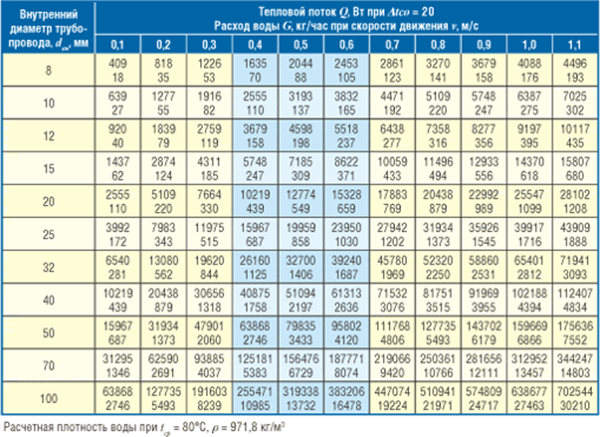

Selection of pipe cross-section: table

The optimal pipe cross-section should be the minimum possible for a given configuration (see table) for the following reasons:

- a small volume of coolant heats up faster;

- a smaller clearance creates greater resistance to the movement of the coolant, it slows down, which results in a reduction in noise;

- a small diameter pipeline will fit better into the interior and will cause fewer difficulties during installation;

- The cost of the pipe depends on its size, therefore thin pipes are more cost effective.

However, you shouldn’t overdo it: in addition to the fact that the small diameter creates increased load on connecting and shut-off valves, it is also unable to transfer sufficient thermal energy.

To determine the optimal pipe cross-section, the following table is used.

Photo 1. Table showing the values for a standard two-pipe heating system.

What parameters are needed?

The following parameters may be found in the description of the characteristics of a specific pipe:

- Inner diameter — the main factor influencing the system performance and taken into account in the calculation.

- External — measured along the outer circumference of the pipeline, affects what holes will need to be drilled in the walls and ceilings.

- Nominal or conditional - approximately coincides with the internal cross-section of the pipe, is selected from a fixed series of numbers according to GOST, is denoted as DN 100. For common values, it is sometimes also designated as the thread diameter in inches, for example: 1/2", 3/4".

Calculation procedure to select the size

Let's consider an example of a typical calculation of the cross-section of a pipeline for heating a room 40 m2.

- Let's calculate the optimal amount of energy to heat the room. For the middle zone, insulated house and ceilings no higher than 3 meters, 10 m2 area required 1 kW warmth. Or for 40 m2 — 4 kW.

- We take 20% reserve (in case of unexpected heat loss in the form of open windows and other factors): 4*1.2 = 4.8 kW, or 4800 W. There should be a heating radiator under each window in the room. Let's say in our room 3 windows, then it is 3 radiators, each by ~1.6 kW.

Attention! The thermal power is indicated in the technical data sheet for the heating battery. You can use a more powerful radiator, but not vice versa, otherwise the room will not heat up efficiently enough.

- Now we turn to the table and we find in the cells the closest power value to the calculated one, rounding up.

According to the table, this is 5518 W and it is necessary to use a pipeline with a cross-section equal to 12 mm, and the speed of the coolant will be 0.6 m/s.

Despite the presence of other similar values in the cells, the values from the blue-colored zone, which contains acceptable values of liquid velocity in the pipeline.

The appropriate flow rate of the coolant through the pipes is from 0.3 to 0.7 m/s. A smaller one will lead to slow heating of the room and uneven heating of the radiators, and with a larger one the liquid will simply not have time to warm up to the set temperature in the boiler heat exchanger and create noticeable noise.

Features of choice in a private house

In case of presence of a central heating main, the diameter selection is carried out similar to apartment heating systemsHowever, if you are designing autonomous heating in a private home, you need to take into account the type of coolant circulation: natural or forced.

Forced circulation of liquid is not so picky about the choice of pipeline cross-section, but the operation of a gravity system with natural circulation is very depends on the diameter of the pipes in different areas.

Here, a larger pipe size means less resistance and better system performance, and some sections of the circuit should have a smaller diameter. For example, when installing a bypass (closing section), its diameter is recommended to be one nominal size smaller than the main pipeline.

Photo 2. Using a bypass in a heating system, in this case the diameter of the pipes should be smaller than that of the pipeline.

Consequences of narrowing the riser in an apartment building

The entire heating system circuit should ideally be made of pipes. one size. Individual narrow sections lead to local increases in pressure and a decrease in fluid flow, which can have a detrimental effect on heating efficiency.

When remodeling the heating system in an apartment and replacing steel pipes with plastic ones, you can inadvertently narrow the diameter in this section. This happens because the thickness of the walls of a polyethylene pipeline is much greater than that of a steel one. So, with the same external cross-section, The plastic pipe will have a smaller internal clearance.

Often this is done only to save time and effort, because the old holes in the walls for steel pipes will have to be widened, and quite a bit: from 25 to 32 mm. It is much easier to save money and install a pipe with a smaller internal cross-section.

However, it is absolutely forbidden to do this because of the serious consequences: in an apartment building, you will steal from your neighbors in the riser in this way 40% heat and water, passing through pipes.

How to choose the diameter of the feed and return in the apartment

In a two-pipe heating system different arrangements of the supply pipes (with hot coolant) and return pipes (with cooled after transferring part of the energy to the room) can be used. If the supply and return pipes run next to each other in parallel and each radiator has an individual connection, then their diameter can be chosen to be the same.

Reference! However, if the pipes are spaced apart and the supply is brought to the attic of the house, from where branches already go to the rooms, the diameter of the supply pipeline needs to be larger than the return one, to ensure sufficient system performance.

Pipeline as a key to efficient operation

The cross-section of the pipes from which the heating system is installed is of great importance for the efficiency of its operation.

Incorrectly calculated diameters can not to show oneself until the right time.

For example, until you change the coolant temperature or try to start the system in a cold house.

If the heating was already working “on the edge”, then changing the temperature regime could lower the pressure to such levels that the system simply won't work.

Useful video

The video provides some expert advice on choosing the diameter of heating system pipes.

Conclusion

In addition to traditional boiler-based heating, geothermal heating is gaining popularity today, using thermal energy stored in the ground from the sun. Special equipment (heat pump) converts low temperature +5–8 °C deep in the earth into heat for heating rooms.

The advantages of this method heating is widespread availability, renewable energy, environmental friendliness and low operating costs. But for now, such installations are too expensive and pay off in 5-8 yearsIn addition, electricity is required to power the pump, which makes such heating completely energy-dependent.