Traditional options are better than many modern ones! Wood heating: pros and cons

Heating with wood is popular, although it is only common in private homes.

The method of heating the premises is the use of wood fuel. As it burns heat is generated, warming the home.

Typically, stoves, boilers or fireplaces are used for heating in this way.

Types of wood heating

There are three options for heating rooms:

- Standard stove heating.

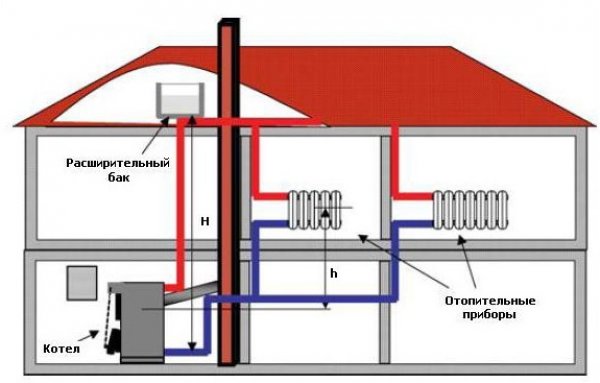

- Water heating, in which a boiler is fired to heat water.

- Fireplace.

Stove

Traditional Russian stove— a relic, although the modern device performs similar functions. The upper part of the stove is used as a place to rest, and the inner part is suitable for cooking. The main function of the device has been preserved: stove heating successfully heats the room.

Feature of the device — the need for a long hood. If the draft is low, it is necessary to build a chimney.

Water

A wood boiler that heats water has an average efficiency. The indicator is higher than a stove boiler, but lower than a fireplace boiler. Advantages — cheapness of the device and installation, fuel economy. The principle of operation is simple: the wood, burning, heats the water in the piping.

Photo 1. Scheme of water heating of a private house using a boiler that runs on wood.

For water heating a small exhaust is required. For combustion low-quality fuel will do.

Fireplace

An open fireplace is not suitable for heating, since its efficiency is only 20%. That's why they use it fireplace stoves. Such designs allow you to enjoy the view of the fire through heat-resistant glass. The draft system makes the smoke give off heat to the device before leaving the room.

Some ovens are improving, in combination with water or air heating. Connected to a water circuit, the fireplace can heat the house using classic radiators. When convectors are added to the design, the stove can heat the home through a ventilation shaft that takes combustion products outside.

Wood fired boilers

Boilers that use wood as fuel, have a simple operating scheme, which simplifies their operation and repair.

The basis of the design is combustion chamber. Logs are placed in it, then they are set on fire. As they burn, fuel is added, and the products of the process exit through a heat exchanger.

Heat-resistant pipes are heated by the heat, giving off heat to the body of the stove and then into the room.

There is a stand under the chamber that collects ash. This part of the device is cleaned 2-3 times a week to avoid clogging. The remaining fuel can be saved for further fertilization of the soil.

The operation of a wood boiler can be described as follows:

- As the fuel burns, it releases heat, which is transferred to the heat exchanger.

- Heat is transferred to the carriers: the furnace body or the water circuit.

- Heat carriers warm the room.

The type of heating affects the type of device. A conventional stove transmits heat to the room where it is located. Water heating consists of heating water, which heats the house through radiatorsAir heating involves smoke removal. through ventilation, the shaft of which is laid along the rooms. The heat gives off heat, and the cooled coolant leaves the house.

Advantages:

- Low cost of the device and fuel. Dried logs from fallen trees are suitable for heating rooms.

- Wood heating does not require obtaining a special permit, like gas.

- The wood boiler is easy to operate. It is enough to light a fire, periodically adding fuel. Every two days the ash stand is cleaned. Every few months the chimney is cleaned.

- Wood boilers safer than gas and electric counterparts, as they are made of heat-resistant materials.

Flaws:

- The boiler requires care and attention. As the fire burns, you need to replenish the fuel, logs need to be stored in advance. The ash stand and chimney need to be cleaned.

- Although wood boilers are inexpensive, they are really high quality construction. has a high cost price.

- For storing fuel A separate building with low humidity is required.

- Combustion product, smoke, leaves behind an unpleasant odor in the presence of poor quality traction.

- Some ovens are bulky, they require increasing the area of the house.

Popular device models

It is worth highlighting well-known and high-quality brands of wood-fired boilers:

- NMK Sibir-Gefest KVO 15 TE.

- Protherm Beaver 20 DLO.

- Bourgeois-K MODERN-12.

First model has a capacity sufficient to heat a building with an area 150 square meters. Device efficiency — 70-75%. The boiler is fired with wood or coal. The heat carrier obtained through combustion of fuel has an average temperature of 70 °C. The heat exchanger is made of heat-resistant steel. The device is equipped with a tubular electric heater with a power of 4 kW. NMK Siberia-Gefest KVO 15 TE weighs 115 kg and holds the pressure up to 2 bar.

Second model has the best performance. The power is sufficient for heating 190 square meters, and the efficiency is about 90%. The coolant temperature is regulated directly and is in the range from 30 to 85 °C. The heat exchanger is made of cast iron, consists of several sections and is divided into two passes. The high efficiency of the Protherm Bobr 20 DLO allows you to recoup the cost of the device by saving fuel. The device is equipped with temperature and pressure control systems.

Photo 2. Wood-fired boiler NMK Siberia-Gefest KVO 15 TE. The device is made in a combination of black and orange colors.

Bourgeois-K MODERN-12 — pyrolysis wood boiler. Control is carried out manually, although there are devices with electronics. The power is sufficient for heating 120 sq. mThe cost of the boiler is due to its high efficiency - 92% and the ability to operate on any fuel: wood, coal, peat, etc. The coolant reaches a temperature of 95 °C by using the compressor. Like the previous model, Burzhuy-K MODERN-12 is equipped with temperature and pressure control systems.

Price

The price of a wood boiler depends on the factory specifications and the manufacturer. It is affected by the heat exchanger material and the presence of electronics that automate control. The cost of the presented models, in rubles:

- NMK Sibir-Gefest KVO 15 TE — 18 thousand.;

- Protherm Beaver 20 DLO — 45 thousand;

- Bourgeois-K MODERN-12 — 55 thousand.

Heating a house with wood

For wood boilers, the appropriate fuel is used. Having prepared the material, it is dried, then processed into small logs. The product is stored in a room with low air humidity. A kilogram of firewood with humidity less than 20% able to give out 4 kW of heat. It is important to monitor the dryness of the fuel, otherwise consumption increases.

How much do you need to prepare?

For production 1 kW energy from firewood will be needed 360 kg fuel. For a standard furnace with a power 150 kW it will take approximately 2.7 cubic meters of forest.

This number is enough to heat a house with an area of 150 sq. m. within a month. Translated into kilograms, it will be about 1.3 tons wood moisture content 20% or less.

Thus, for the winter you will need about 4 tons of wood.

The combustion process

Logs are set on fire and added to as they burn. The firewood is kept in a special room where low humidity is maintained, but some of it is located near the boiler. This way, the fuel is dried by the heat of the device.

The boiler is cleaned every week. This will help maintain high efficiency of the furnace.

Attention! Once in a 5-6 months clean the chimney, which improves removal of harmful combustion products.

The ash stand is cleaned as it accumulates.

Useful video

Watch a video that talks about the features of heating a 250 square meter house using a wood boiler.

Savings and efficiency of wood heating

For heating a lot of firewood is needed, but this one The material is quite cheap. The stove device is also inexpensive and together with the piping will cost a small amount. In addition, wood heating allows you to save on electricity and is an effective way of heating rooms. High-quality devices have high efficiency. A good indicator allows saving fuel when heating small buildings.

Comments

We buy ready-made firewood for the stove and store it in my woodpile under a canopy, protected from precipitation and when it lies for a long time, it still dries out. In addition to this, I always keep some firewood opposite the stove and as it is used up, I replenish it from the woodpile. I have never calculated the amount of firewood required, I just order a truck and then all that remains is to put it in the storage place.