Reducing costs by increasing comfort: choosing a heating element for heating radiators with a thermostat

TEN - abbreviated name tubular electric heater, used to heat a liquid medium.

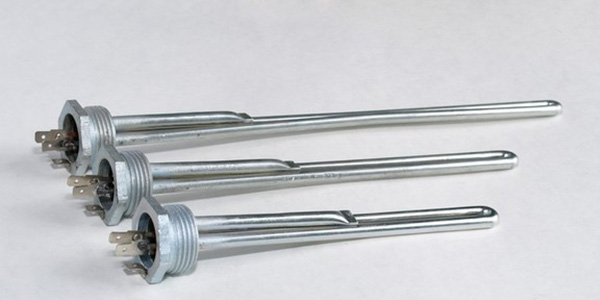

The device is made in the form of a tube in which is enclosed spiral heating element.

The device is built into the radiator and converts electrical energy into thermal energy, ensuring heating of the coolant.

In what cases is a heating element used for radiators?

Tubular electric heaters can be installed in any Heat exchangers with internal chamber, filled with liquid. As a result, heating elements are used very widely.

They are installed as primary and auxiliary heating sources in the following cases:

- When occasional heating of a summer house or garage is needed, utility and auxiliary rooms where there is no main source of heat, radiators.

- For continuous heating of houses, offices, industrial premises without a central heat generator.

- As an auxiliary heater in circuits with a solid fuel boiler without automatic fuel supply function.

- For heating networks operating on expensive fuel subject to the use of a night tariff for electricity and the installation of a multi-tariff meter.

- As an alternative heat source, which protects the system from freezing in an emergency.

- In houses with central heating during severe cold weatherwhen the thermal power plant resource is insufficient.

When installing heating elements with a thermostat in insulated radiators for periodic heating, the coolant moves only inside the housing.

To prevent a disconnected battery from freezing, use for filling low viscosity technical oil.

When organizing heating for rooms with continuous heating, water can be added.

Note! When installing heating elements with thermostats in apartment buildings with centralized heating, shut-off valves and a bypass jumper must be installed. Shut-off valves It is necessary to prevent heat from escaping to the neighbors; without a bypass, the common house heating network will not work.

Additional functions

Tubular electric heaters are equipped with automatic control temperature control.

Thermostats of various types (capillary, rod) maintain the required temperature of the liquid in the radiator, starting and stopping the heating process in time.

Modern models are often supplemented with the following functions:

- "Anti-freeze" - maintaining a temperature of +10º C, at which the coolant will not freeze.

- "Turbo" - works at maximum power for very fast heating of the room.

Automatic tubular heaters can be built-in or externalIn addition to optimizing operation, thermostats ensure safety – they disconnect heaters from the power supply in the event of breakdowns or malfunctions.

The operating principle of devices with thermostats

Operation of heating elements with thermostats based on the laws of physics. After switching on, the spiral heats up, warms up the filler and the body, the heat is transferred to the coolant located around the heater. The hot liquid has a lower density, therefore it is pushed upward by the cold masses, and the cooled masses fall in its place. The cycle repeats continuously, while the unit is running.

Peculiarities

- Devices for radiators are distinguished by a narrow heating element and flange.

- Thermostats provide high accuracy of temperature setting.

- There is a control sensor on the body, preventing overheating.

- Pulse operation helps save energy.

- To protect against a humid environment, heating elements are equipped with protective covers.

- Tubular heaters are installed not only in cast iron radiators, but also in batteries made of other materials.

- Heating elements are easy to install, no permitting documentation is required for installation.

Choice: 4 main parameters

To ensure that the device works long and efficiently, the following should be taken into account when purchasing:

- Power. Calculated taking into account the region, heat loss of the building, and the area heated. Approximate value for the central zone of the Russian Federation — 1 kW of energy per 10 m2.

Attention! When a heating element is needed as an additional heater, a power of 75% of total heat output radiator. Otherwise, you will overpay for a resource that will not be used due to the constant shutdown of the heating element.

- Length. The factor affects the circulation of liquid in the radiator and the uniformity of heating of the sections. The length of the tube is selected 7-10 cm shorter than the radiator.

- Purpose. The design of heating elements for different types of batteries does not have any fundamental differences, except for the material and diameter of the flange plug. Therefore, before purchasing, study the manufacturer's recommendations.

- Automation. Heating elements are produced in two versions: with a thermostat built into the case and with an external control module. The former are cheaper and are suitable for additional heating. The latter are connected using additional external electronics and are more often used as the main heating device.

For cast iron batteries

Electric heaters with thermostat for cast iron radiators differ from others diameter of the plugIts typical size is 32 mm, which according to plumbing canons is equal to 1 1/4 in. Information about the heating element’s compliance with a certain type of heating equipment is always available in the technical data sheet.

To achieve maximum heating completeness, also take into account the heat transfer of cast iron sections, linear dimensions, and type of control electronics.

Photo 1. Three heating elements for cast iron batteries of different lengths, made of stainless steel.

For heating boilers

It is installed in boiler equipment 1-3 or more tubular electric heaters or special heating blocks. If the device needs to be replaced, the following parameters are taken into account:

- heating element power - must comply with the characteristics declared by the boiler manufacturer;

- type, voltage of the electrical network;

- shape, dimensions of the electric heater;

- heating element type - "wet" or "dry", the latter does not come into contact with liquid, therefore a coolant of any quality is used;

- the presence of a thermostat.

The main rule when replacing a heating element is: choosing a device brand, permitted by the boiler manufacturer.

Photo 2. Heating element for an electric boiler for heating water with a high power of 6 kW, equipped with a thermostat.

Installation of a tubular electric heater

The installation process for any heating element with a thermostat is the same and does not depend on power and type. Installation is carried out according to the following scheme:

- Draining water from the radiator of an autonomous system, in the centralized heating network. Installation is carried out before the start of the heating season.

- Removing the battery cap.

- Install the heating element strictly horizontally.

- Fixation by means of a threaded connection.

Important! To create proper circulation, and therefore uniform heating, an electric heater with a thermostat screwed in instead of the bottom plug!

Useful video

In the video you can see what happens to the battery and heating element after several years of use.

Are they any good?

Electric heaters help transform home batteries into a fully autonomous system with minimal expenditure of resources, effort and time. Since they are in direct contact with the heat-carrying medium, giving it all their heat, then have high efficiency.

The most economical models are those equipped with a thermostat and auto-off sensor. They provide a comfortable level of air heating and eliminate the waste of electricity on excess heat.