A simple, yet economical and effective option for the home - steel heating radiators

You are viewing the section Steel, located in the large section Types.

Radiators in heating systems can be made of cast iron, steel, aluminum, as well as combinations of metals – bimetallic.

The material is of decisive importance when applied to heating systems of various types.

Due to the peculiarities, steel radiators have found wide application in small autonomous systems in the private sector. Such batteries are characterized by low cost and ease of installation.

Content

Description of steel heating radiators

At a relatively low cost, steel has high strength, plasticity, flexibility, thermal conductivity and good fusibility when welding.

The main disadvantage is low resistance to corrosion. The thickness of the steel varies among different manufacturers. from 1.5 to 1.25 mm, and the higher this indicator, the better the quality of the product.

Heat dissipation

Steel radiators heat up quickly and have high heat output at the level 200-1800 W. Larger figures are also possible depending on the dimensions, manufacturer and type of model.

Working pressure

Due to the large number of welds, steel radiators cannot withstand the high pressure that sometimes occurs in central heating systems. The working pressure depends on the type of radiator and is different for panel and tubular designs. first it makes up 6-10, the second ones have 8-15 atmospheres.

Coolant temperature

The coolant temperature can reach up to 110-120 °C.

Typically, such temperatures do not occur in centralized heating systems.

At the same time, this indicator can significantly improve the properties of a small autonomous system.

Device: pros and cons

The principle of operation of a steel radiator is no different from batteries made of other materials. The heating panel is connected to the pipe through which the coolant is supplied. The pressure and temperature are regulated by a valve. Radiators are attached to the coolant supply pipes from the side or from below.

With regard to the internal design of the cavities, a distinction is made between panel, tubular and sectional batteries.

Pros:

- Cheaper batteries made of aluminum and cast iron.

- Diversity offers on the market.

- High performance heat transfer.

- Simplicity constructions.

- Light weight and ease of installation.

Cons:

- Vulnerability to corrosionManufacturers have not yet found reliable protection against corrosion, although there are options that alleviate this problem to varying degrees.

- They can't stand it high pressure due to welded seams.

- Among consumer reviews, there are often mentions that on steel radiators the paint doesn't hold up well, peeling of decorative coatings occurs.

Suitable for heating country or private houseIn a centralized heating system, which is most often found in apartment buildings, it rusts when the coolant is drained, does not withstand pressure during hydraulic tests, and reacts poorly to oxygen that enters through the pipe system.

Attention! It is not recommended to install in damp rooms.

Types of steel batteries: photo

There are the following types of steel radiators.

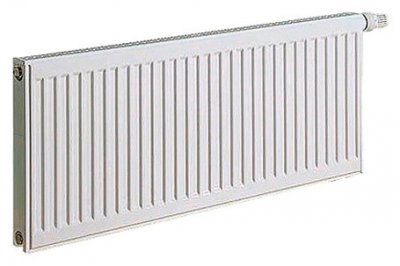

Panel

Made from low carbon steel sheet. For manufacturing one panel two sheets metals are stamped in such a way that when welding, channels are formed between them through which the coolant will flow. In the design one radiator may be counted up to four heating panels.

Photo 1. Steel panel radiator model C 22500x1000, heat output 1857 W, manufacturer - "Purmo", Finland.

Flat homogeneous panels by themselves heat the room worse than batteries with voids in their design. To increase heat output Fastening from the reverse side is possible convector panels, which are steel ribs in the shape of the letter "P".

The air circulating along these ribs is heated to a greater extent, which allows the principle of convection to be implemented in the room, when a well-heated air flow along the wall rises to the ceiling, displacing the cold air, which again flows along the opposite wall and along the floor to the radiator.

Batteries may contain up to four heating and convector panels. The unification of such structures is carried out, among other things, by an external casing.

Pros:

- the lowest price of all types of steel radiators;

- diversity models available on the market.

Cons:

- the greatest weight among the family of steel radiators;

- labor intensity of cleaning if there are convector panels;

- You must not drain water from risers in the warm season;

- high susceptibility corrosion;

- increased hydraulic resistance due to the small cross-section of the circulation channels.

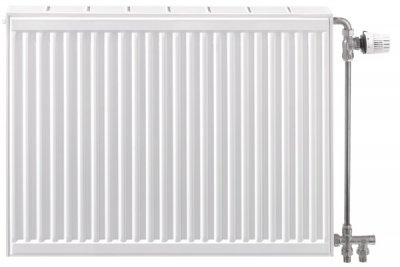

Tubular

The radiator looks like a classic battery, but one vertical section can contain from two to four steel tubes. The diameter of one tube is approximately 25 mm. Collectors are placed perpendicular to the pipes at the top and bottom of the battery.

In addition to the classic design, there are models with tubes arranged parallel to the collectors.

The model range includes various forms, including angular and curved ones.

Photo 2. Steel tubular radiator model 2057, two-pipe with side connection, manufacturer - "Arbomia", Germany.

Pros:

- Fine distribute heat.

- Due to the lack of convector grilles, as in panel heaters, easy to clean.

- None sharp corners, therefore less dangerous.

- Withstand higher pressure: working 10 and pressure testing 15 atmospheres.

Cons:

- High cost compared to panel ones due to the large amount of welding work.

- Are susceptible corrosion.

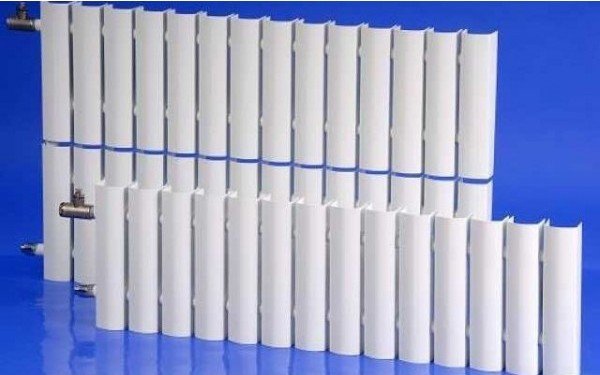

Sectional

Sectional batteries are similar in design to tubular batteries, but they are equipped with fastening of each individual section, which provides additional opportunities for manipulating the length of the entire battery, as well as repairing and replacing sections.

The tubes through which the coolant circulates have a channel at the top and bottom with double thread for connecting nipple. On the outside - steel shell.

Photo 3. Steel sectional radiator KCM-2 with side connection, manufacturer - "KCM", Ukraine.

Sectional steel batteries are distinguished by their increased strength and resistance to possible pressure drops.

Pros:

- More durable and long lasting compared to radiators of previous types.

- Advanced Features repairs.

Cons:

- The cost of production is too high, therefore they cannot compete with panel and tubular heaters.

How to choose the best model

The preference for a particular heating panel model depends on financial opportunities, parameters premises, like heating system and requirements regarding health people living or forced to stay indoors for long periods of time.

Radiator type

Most budget type are panel radiators, but they are difficult to clean, and dust accumulates in convector panels.

As a result, they are not recommended for use in children's and medical institutions, as well as for allergy sufferers. In these cases, you should choose between tubular and sectional models.

In addition, panel radiators are most sensitive to pressure in the heating system due to the small cross-section of the channels.

Height

The selection of a model by size is determined by the parameters of the room - height of window sills, under which the heaters will be installed. And also take into account the required power, which is also related to the dimensions.

Reference! Panel type radiators have a height from 20-90 cm, tubular - from 19 to 30 cm.

Power

The capacity of the heating battery is specified by the manufacturer. During operation, it depends on the temperature of the supplied coolant. The type of radiators and their number for installation is affected by number of windows and room size. The preliminary calculation of the required power is determined by multiplying the area of the room by 100.

Pipeline diameter

The internal diameter of the connection is specified by the manufacturer and should not differ much from the diameter of the heating system.

Ideally, these two parameters It is better to plan at the same time as installing the entire system.

Installation methods: bottom connection or wall-mounted

Since steel radiators are lighter than cast iron ones, they are most often placed in a wall-mounted version.

However, if the walls are not suitable for this option, you can choose a floor heater with a bottom connection.

DIY installation

All types of radiators are installed in single sequence. Steel panels and tubular heaters are lighter than cast iron ones, which makes them easier to work with. The installation process requires attention and a certain level of precision, but you can do it yourself without the help of professional plumbers.

Attention! Materials and tools required for installation: level or a regular bubble level, fasteners, supplied with the battery, drill, screws, winding and equipment for connections pipes.

Marking the walls for fastening

The placement of heating devices under the windows is explained by the need to cut off cold air with a warm flow.

To prevent fogging, the depth of the heater should be more than 75 percent window width.

The radiator is positioned horizontally relative to the center of the window opening with an acceptable deviation 2 centimeters.

The distance from the window sill to the top edge should be 10-12 cm, to the floor - 8-12 cm. Distance from wall of fastening — from 2 to 5 cm.

Attention! Steel heaters are more often used in systems with natural circulation of the coolant. The radiator is suspended with a downward slope away from the input, that is, if the water comes from the right, then the left side should be lowered. by 1 cm. With a short radiator it is enough 0.5 cm.

After the necessary markings have been made and the fasteners have been installed they are trying on unconnected radiator with level measurement, after which you can proceed to the adjustment work of the heating system.

Installation

?

?

When the radiator is installed in an existing heating system, it is necessary to disable it. All metal components for connection must be at hand.

If necessary the residual water is drained, The heating pipe is cut at a pre-marked location. Shut-off valves with the ability to regulate are installed at the inputs and outputs.

The thread is sealed with a winding, a packing mastic is applied on topAfter a short period of time, a test run is carried out, gradually turning on the taps.

Connection diagrams

The radiator model should be selected according to the possible connection scheme. It is determined parameters of the heating system and the strength of the material, from which the walls of the room are made. The methods of lower connection are strictly dictated by the manufacturer. When connecting from the side, the following options are possible:

- One-sided: the input and output are located either on the left or on the right.

- Diagonal: entrance at the top, exit in the opposite corner.

- Saddle: the input and output are located at the bottom.

Features of use in a private home

The special appeal of steel radiators is their affordable price, and their main disadvantages - susceptibility corrosion and the impossibility of holding on water hammer — appear in centralized systems of multi-story buildings.

Thus, owners of private houses with autonomous controlled heating systems can take full advantage of the affordable prices and variety of steel radiators.

When planning a heating system for a private home, the owner can simultaneously take into account the parameters of the radiators and select the best options.

Useful video

Check out the video that explains the advantages and disadvantages of steel radiators compared to batteries made of other materials.

Demand

Due to the fact that private construction is growing at an accelerated pace, steel radiators are among the the most popular heating devices. According to some estimates, they occupy more than 2/3 of the market.

Comments