Truly royal in scope: industrial smokehouses with a capacity of over 1000 liters

IN restaurant business, and also in manufacturing companies, specializing in the production of smoked delicacies, widely use special industrial smokehouses.

These large and multifunctional The units allow you to prepare delicious meat, fish, cheese and other products in large quantities using cold and hot smoking.

The design of these devices is characterized by the presence of timers, multiple modes, temperature and humidity control systems, as well as some other functions.

Smokehouses for restaurants and other small businesses

At enterprises big business predominantly, units equipped entirely with automated complexes for processing food products and their subsequent packaging.

For small production workshops and private business are quite suitable simplified versions.

They can be built on one's own, having first understood all the design and technological principles.

Features of industrial hot or cold smoking

The smoking process combines several successive stages, aimed at creating the characteristic features inherent in a tasty smoked product - a special color, aroma and consistency:

- preliminary ambassador food raw materials;

- heat treatment;

- getting rid of leftovers liquids;

- organic matter treatment, which are formed as a result of incomplete combustion of wood.

There are two methods of smoking: hot and cold. The second option provides longer shelf life products.

Processing food in smokehouses hot smoked provides for three important stages: drying, baking and smoking itself. In such devices, the preparation of smoked meat and fish products occurs at temperatures from +80 to +170 degrees.

This allows the food to retain more natural moisture, making it soft and juicy. Storage period products prepared by hot smoking are no more than three to five days.

Cold method allows you to preserve the maximum amount of useful properties of products. The temperature for this smoking method is only +40 degrees.

Dehydration food raw materials are exposed to table salt and hot smoke. They are also dried by smoke, which helps them acquire a pleasant golden hue.

Reference. Method cold smoking is optimal for cooking fish, meat hams, briskets, and also dry-cured sausages.

To obtain the highest quality product, it is recommended to set the level temperature +20°C and humidity ― 50%The smoking process takes approximately 1 hourFood prepared in this way retains its characteristics. from 5 days to 3 months, it all depends on the quality of the packaging, pre-salting and subsequent storage.

Process salted hams last 30 days, and loins and brisket ― 20 days at an average temperature of about three degrees Celsius.

Drying semi-finished meat products are processed at a temperature +20°C, after which they are treated with thick smoke. This requires gradually increase the temperature, and the intensity of smoke, on the contrary, decreases.

Preparation of dry-cured sausages is carried out throughout 5 days at a temperature of about +20°С. Smoke treatment helps protect meat from rapid spoilage. To maintain the correct weight of the sausage product, it first cool to +4°C, and then at +10°C dry for one month.

Scheme, structure and functions of industrial smokehouse

Main component device - camera for smoking, made in the form of a tower or tunnel. Tunnel The designs allow for large volumes of production and imply convenient division into technological processes. Tower Smokehouses are characterized by a vertical arrangement of chambers, their height varies depending on the model.

The following are used as power sources for the units: electricity or gas. Professional production devices differ from regular home and camping options in their more impressive dimensions, as well as multitasking.

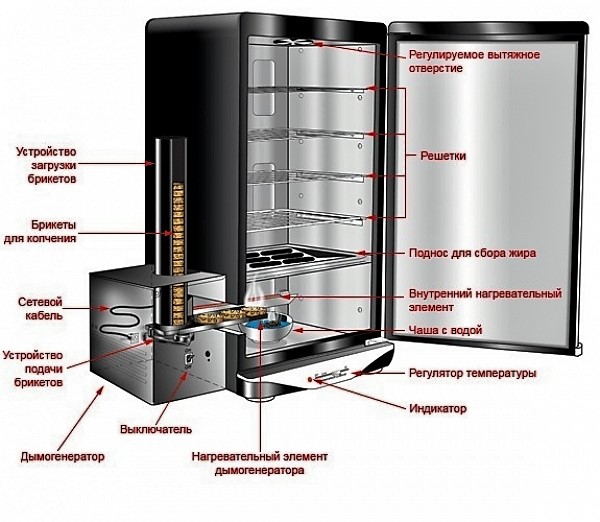

Photo 1. Diagram of the internal structure of a professional automated smokehouse. The main parts of the device are labeled.

Optimal dimensions for such structures: height ― from 1 thousand to 1300 mm, width 700-750 mm and depth 800-850 mm.

Important! Since all processes in industrial units automated.

Their mandatory functions are:

- software to set up and save the smoking scheme;

- timer works;

- display and remote control for automatic control.

Material of manufacture

The best professional smokehouses are made from stainless steel, since it is characterized by excellent performance properties.

Important! How more size of the unit, tem thicker its walls must be.

For multifunctional mini-smokehouses, widely used in the catering industry, it is enough thickness walls 1.5-2 millimeters. Devices installed in large manufacturing plants should ideally have walls with a thickness of not less than 3 mmThis will ensure the correct smoking process and prevent deformation of the device.

Useful video

Video review of a 1500 liter wooden industrial smokehouse with lighting, fans and a control panel.

Main characteristics of a professional smokehouse

A high-quality smokehouse for industrial use is capable of functioning in several modes: smoking, drying, heat treatment (cooking and frying).

Thanks to special technologies, it is carried out temperature control products and air in the chamber, humidity level and cooking time. Depending on the temperature setting, the device is capable of smoking products. in three different ways - cold, hot and semi-hot.

Optimal material is a durable stainless steel with a thickness from 1.5 to 3 mm - this will ensure high quality smoking and a long service life of the device.

Comments

Industrial smokehouses have a lot of additional functions, various timers and grates that increase production, but the average person doesn't need it. I recommend reading this article - https://thermo.washerhouse.com/en/stroitelstvo-svoimi-rukami/koptilnya/iz-chego-sdelat/iz-dereva.html And you will be able to make a smokehouse at your dacha without any outside help.