Provides reliable protection for the system - a safety group for heating

The safety group (SG) for heating is an integral part of the heating system, guaranteeing the safety and trouble-free operation of its.

The entire structure consists of a pressure gauge, an air vent and a safety relief valve.

Content

Purpose

The protective device performs the following functions:

- prevents leaks from occurring from shut-off valves;

- prevents breaks pipes;

- eliminates the formation of faults in the elements heating systems under high pressure.

Thus, The safety knot helps control the pressure level. If it becomes critical, the safety group reduces it by releasing the required volume of coolant.

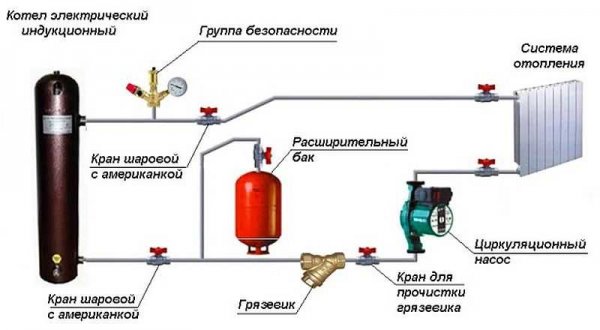

Scheme of construction with expansion tank, principle of operation

The heating safety group consists of:

- safety (emergency) relief valve;

- automatic air vent;

- pressure gauge.

It is used as one of the main elements of the heating system. expansion tank. It performs the function of a pressure level stabilizer in all circuits of the system to prevent its imbalance. The expansion tank compensates for the volume of the coolant, thereby relieving the pipes and other elements involved in its (coolant) circulation from loads.

The emergency valve, air vent and pressure gauge are fixed to the console.The first two elements are attached to the base by hot forging.. Each component of the heating protection unit performs its own function.

Photo 1. Diagram of a heating system using a boiler, expansion tank and safety group.

Manometer

He designed for visual display of the pressure level in the networkThe device is scale with two arrows, Where black is the working one, and red is the control one. The last of these is set in accordance with the boiler passport. If the black arrow goes beyond the red one, this indicates a failure in the system.

Features of installation of safety valve

He discharges the coolant in order to reduce the pressure in the system. The direction of the discharge is indicated by an arrow on the device itself. This is done to ensure that the discharged coolant does not fall on people.

Often the safety valve is located above the boiler. Then the liquid from the safety valve will fall on it when released. This is unacceptable, especially if it is electric. To avoid such a situation, it is necessary connection of a tube to the discharge valve, under which a container for liquid is placed.

How does an air vent work?

This element of the safety group for heating removes air released from the coolant brought to a high temperature.

The air vent must be located at the highest point, above the boiler., where the air bubbles will be directed.

Photo 2. Safety group for the heating boiler. Includes a pressure gauge, air vent and safety (check) valve.

Before starting the air vent operation it is necessary to turn the locking cap a few turnsThis element is very sensitive to contamination.

Important! When installing an air vent, it is necessary to provide a heating system coolant cleaning devices.

How to choose a safety group for a heating system

Each model of such protective mechanisms has certain design parameters, specified in the accompanying documentation to her.

When choosing such a device It is important to pay attention to the following criteria:

- The power for which the boiler is designed.

- Nominal pressure.

- Maximum coolant temperature (up to 120 °C).

- Thread diameter of the connection. If problems with the connection arise, adapters of the required connector will do.

It is also necessary to take into account what coolant the selected protective block is compatible with: water, antifreeze or steam.

How to install it yourself

To carry out the process you will need the following materials and tools:

- emergency relief valve;

- air vent;

- pressure gauge;

- flax;

- crosspiece;

- angles with external and internal threads;

- gas keys;

- nipple;

- sealant;

- adapters.

Using flax wound clockwise onto the thread, The corners are attached to the crosspiece. A layer of sealant is placed on top of the flax using wrenches the corners are fixed opposite each other.

All components of the GB are mounted according to this scheme. The parts are connected using adapters.

After assembly, it must be tested under pressure. for possible malfunctions and functionality.

Installation of a safety group on a heating boiler

Before assembling a security group, determine the location for installing such a device. The main conditions for its selection:

- On the supply line above the heating boiler at a height up to 1.5 meters.

- A horizontal section of pipeline in close proximity to a heat generator.

- On some types of boilers, there is a special connector on top of the heat generator to secure the GB.

- For the pipe going up from the heating boiler, a safety block is mounted by installing a horizontal plane. On it, all the components of the group will "look up".

- For a high-power boiler, it will be necessary to install another safety unit.

To start the system The cap in the air vent is unscrewed and the air is released. The lid is then returned to its original position and the device is left open.

Attention! It is prohibited to install shut-off valves between the boiler and the safety unit. Otherwise, in the event of an accident, the protective device will cease to operate.

Once a month It is necessary to check the serviceability of the air vent. Long periods of downtime in operation lead to its clogging.

Useful video

Watch the video to learn how to make a safety group for heating systems.

The need to use a protective block

The protective block is a mandatory element of the heating system. It is capable of provide reliable protection and prevent possible network failure as a result of a sharp pressure surge, while requiring a minimum of human intervention.