Gourmet Device - DIY Wooden Smokehouse

A wooden smokehouse is a useful household item that will help diversify your diet with delicious food.

It is not difficult to make such a device.

By wooden smokehouse we mean a set of specialized equipment and a wooden chamber, which will be filled with smoke.

Content

Advantages and disadvantages of cold and hot smoking smokehouses made of wood

Wooden smokehouses many advantages. These structures are made of easily processed material, so the smoke chamber body can be of any shape and size. It can be decorated with carvings, tinted with impregnations.

Photo 1. Wooden smokehouse for hot smoking during cooking. Equipped with retractable slats on which you can hang products.

Another advantage of the designs is availability and wide choice of materials for manufacturing. In the process of work you will need tools that are available in every home: a hammer, a screwdriver, a hacksaw, screwdrivers.

Unlike metal smokehouses, wooden devices can be insulated. This will ensure stable temperature inside the smoke chamber. Materials that do not emit harmful substances when heated are chosen as heat insulators. These are ecowool, mineral wool, sawdust and shavings, felt, expanded clay, and pine needles.

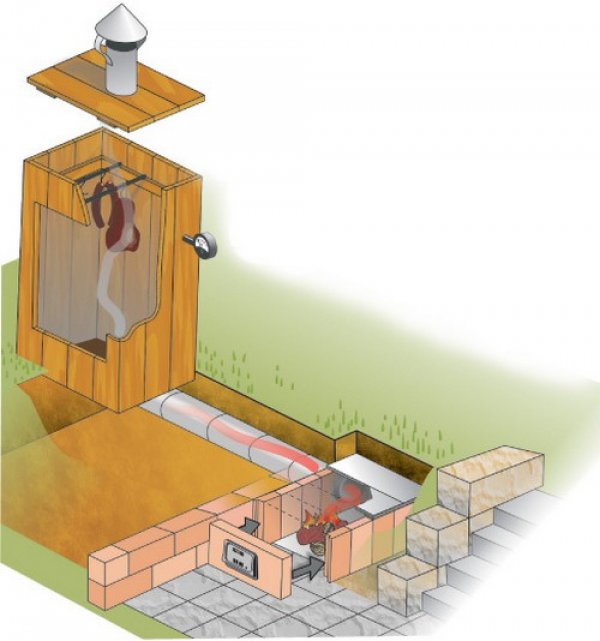

Standard diagram of a wooden smokehouse with a smoke cabinet

Standard Wooden Cold Smoking Smokehouse consists of the following elements:

- smoke chamber (cabinet) 90x60x120 cm;

- metal tray 55x85 cm;

- 2 grates made of wood or metal 90x60 cm;

- wooden legs height from 15 cm;

- plastic or metal flue pipe with a cross-section 50 mm;

- chimney pipe cross-section 100 mm, length 3 m;

- roofing materials for roof protection (slate, corrugated sheets, metal tiles, roofing felt);

- a firebox (furnace) made of metal or brick, which is located at a distance not less than 3 meters from the smoke cabinet.

Photo 2. Cold-smoked wood smokehouse. The firebox is made of brick and is located underground, connected to the smoke cabinet by a smoke exhaust.

The products are placed on the grates installed in the smoke chamber. The tray is designed to collect fat. The legs are necessary to give the structure stability. It is possible to mount a grill into the wall of the smoke chamber. thermometer to control the temperature regime.

The smoke cabinet and the firebox are connected by a chimney pipe. A chimney pipe is cut into the roof of the smokehouse. It is closed with a damper (rotating valve). The function of this element is to adjusting the traction force.

Materials for production: timber, planed boards, plywood and others

Non-resinous wood species are suitable for making a wooden smokehouse. These include:

- cedar;

- oak;

- alder;

- linden;

- birch;

- aspen;

- spruce.

You can use the following materials:

- plywood thickness from 8 mm;

- planed boards;

- lining;

- bars of any section;

- wooden block house.

It is not recommended to use laminated boards impregnated with adhesive compositions: OSB, chipboard, MDFWhen these materials are heated, they will release substances harmful to human healthIn addition, under the influence of temperature and moisture, these canvases can delaminate.

Before using the boards to build the smokehouse, they need to be treated with an antiseptic. Pinotex, Pirilax, Senezh EKOBIO.

Attention! When choosing a tree, pay attention to number and size of knots. During the heating process of the boards, these knots will deform and fall out. This will damage the integrity of the smoke chamber, which is unacceptable. Therefore, it is recommended to purchase high-quality, non-resinous wood.

It is advisable for the master to have such power tools as: jigsaw, drill or screwdriver. They will significantly facilitate and speed up the work process. You will need a tape measure, a ruler, a building level, a square, and a simple pencil.

Selecting a project

The smokehouse project includes: its plan location on the site And drawings of structural elementsDimensions are indicated for each part.

First of all, the desired dimensions of the smoke chamber body are determined. You can focus on the proposed standard scheme of a wooden smokehouse.

Next, they decide what shape the roof will be. There are several possible options:

- flat;

- single-pitched;

- gable roof (house-like);

- trapezoidal.

The easiest roof model to make is flat. A slightly more complex structure is a single-pitched roof located at an angle. 5—20 °C relative to the ground level. The smoke exhaust pipe can be placed on any part of the roof: left or right.

The inlet for the chimney pipe can be at the bottom of the smoke chamber wall or at its bottom. The choice depends from the method of connecting the smokehouse to the fireboxIf it is decided to lay the chimney below ground level, the inlet is made in the lower wall (in the bottom).

Stages of making the device with your own hands

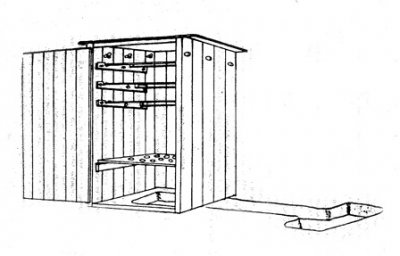

Instructions for making a wooden smokehouse with the dimensions of the chamber are offered 90x60x120 cm.

Smokehouse base

The main elements of the smokehouse frame are: 4 wooden blocks section 50x50 cm and length 150 cm. These will be the vertical posts of the smoking chamber. The length of the bars is selected with the following calculation: the height of the chamber 120 cm and legs 30 cm.

In addition to the vertical posts, you will need horizontal crossbars made of the same material (bars 50x50 mm). In total you will need 4 bars length 60 cm And 4 bars length 90 cmTo connect horizontal and vertical posts, use metal corners, wood screws, and a screwdriver.

Frame

The frame is covered from the inside with the material chosen as the main one.

The boards (plywood, lining) are attached to the posts using nails or screws. Since the cross-section of the wooden bars of the frame 50x50 mm, a free space of width is formed between the inner and outer cladding 50 mm.

Insulation with a thickness of 50 mm.

The optimal choice is mineral wool slabs.

If it is decided to use loose insulation (sawdust, firewood, pine needles), it is filled in after the completion of the cladding of the outer walls of the smoking chamber.

Important! It is advisable to prevent fibers or particles of insulation from getting on food products. To do this, the inner lining of the smoke chamber (from the insulation side) is closed food foil and only after this the thermal insulation material is laid.

The final stage of work on the manufacture of the body of a wooden smokehouse is cladding of external walls over insulation.

Roof structure

In accordance with the selected project, a single-pitched or double-pitched roof is erected. It is also possible to leave it flat. In the upper ceiling (upper wall of the body) an opening is made for the smoke exhaust pipe. The pipe is installed and the gaps are sealed in any way: tow, heat-resistant sealant, mounting foam.

The outer side of the roof is covered with roofing material, having first made a lathing from bars with a cross-section 20/40 mm or 30/40 mm. In this way, the ventilation gap required by the technology is formed, which will prevent over-moistening of the wood with all the consequences: rotting, formation of fungus and mold.

Photo 3. The process of making a wooden smokehouse at the stage of installing a gable roof.

Grilles

The grates for the smokehouse can be made from durable wooden slats with a cross-section 10x15 mm or 10x20 mm. The length of the slats corresponds to the depth of the smoking chamber - 60 cm. All elements of the lattice are located at a distance 3-4 cm from each other.

Pallet

It is recommended to make a metal tray to collect fat. It is much easier to clean than a wooden one. It is advisable to use food grade stainless steelA rectangle of the size is cut out of the metal with a grinder 55x85 cm.

From each side, step back to the center of the rectangle 1 cm and draw the corresponding lines. Along these lines, make shallow cuts with a grinder with a thin (1-1.5 mm) with a metal disk. According to the cuts made, the stainless steel sheet is bent. The sides of the tray are obtained. Its corners are tacked together by welding or tightened with bolts.

Smokehouse assembly

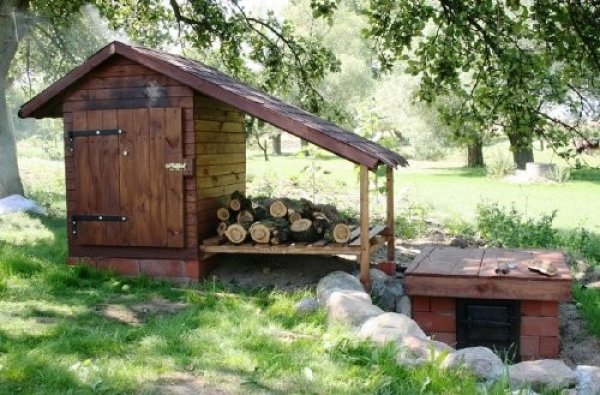

From bricks or sheets of metal make a firebox, which should be located at a distance 3 meters from the smoke chamberA chimney pipe is embedded in the firebox, the opposite end of which is connected to the smoking chamber.

Photo 4. Ready-made cold smoking smokehouse with a brick firebox and a place for storing firewood.

Operating recommendations

The wooden smokehouse can be installed on any free space of the site. Despite the fact that the firebox and smoke cabinet are separated, it is necessary to observe fire safety measures: monitor the intensity of combustion and smoldering of shavings, control the temperature of the smoke in the chamber.

Useful video

Watch the video, which demonstrates step-by-step, in the form of a slide show, the manufacture of a cold smoking smokehouse from wood.

Comments

That's why I simply made two smoking chambers and use the chamber I need as needed.

The firebox itself, as described here, is made of brick and remains in place permanently.

Smoke is fed into the smoking chamber, during cold smoking, through a sealed pipe into the smoking chamber and there, finally cooling, settles on the products and, of course, on the inner walls of the chamber.

But as a smoke generating device, it is best to use a portable smoke generator made from a metal pipe, rather than constructing a permanent device from brick.