Heating without hassle! Using an electric boiler in a garage: principles of operation of the device, installation

Organizing heating in a garage without a central heating system can be a non-trivial task if you don’t approach the issue creatively.

Choosing the optimal heating system allows you to create normal conditions for starting the car And eliminate excess moisture in the room.

Electric boiler mounted in the garage, can solve the problem of maintaining a comfortable temperature around the clock and ensure uninterrupted heating in summer and winter.

Types of electric boilers for heating a garage

The electric boiler does not require complex installation, maintenance and a large number of permits for its installation. When choosing a device take into account the operating principle and associated limitations.

Electric boilers installed in garages, They differ in the way the coolant is heated and their internal structure:

- Heating elements boilers. They are a heat-insulated container with a tubular heating element located inside. The disadvantages are: indirect heating of the coolant, large heat losses, and also the long time required for the unit to reach operating capacity.

- Electrode boilers. Devices of this type use two electrodes that modulate an alternating electromagnetic field with a frequency 50 Hz, which makes the salt ions dissolved in the coolant move, providing almost instantaneous heating of the coolant. Energy efficiency 40% higher, than heating element boilers. The disadvantage is the use of a large amount of salt in the heating system.

- Induction boilers. They use an alternating electromagnetic field created by a copper core, which creates eddy currents of Foucault, heating the metal. It, in turn, transfers heat to the circulating liquid. Induction boilers produce indirect heating of the coolant. They have a long service life and are economically advantageous compared to heating element devices.

Reference. For electric boilers of the listed types there are pros and cons, which must be taken into account when choosing the appropriate model for a specific room.

How to make a choice?

When choosing an electric boiler, In addition to design features, the following is taken into account: its cost, operating features, manufacturer's name, and the required power.

Of the devices available on the market, The most expensive are heating elements and induction ones models. The estimated cost is 25-50 thousand rubles. Less expensive models are represented by electrode boilers, their purchase will cost approximately 9-15 thousand rubles.

Economical electrodes Boilers have their own significant disadvantages associated with the use of salt in the coolant and the impossibility of pouring antifreeze into the system. This, in turn, limits their use to only permanently heated premises.

Photo 1. Electrode-type electric boiler (black device) connected to the heating system.

Heating elements The boilers have the design capability to maintain a minimum heating of the coolant, preventing the system from freezing when cold weather sets in.

Induction The boilers work with any coolant, including antifreeze, ensuring the functioning of the system in extreme cold.

Best brands garage electric boilers, presented on the market by foreign and domestic manufacturers:

- Heating elements boilers: EVAN EPO, Elvin EVP, Delsot EVP, Resurs EVPM, Novel EVOS, Teplotech EVP.

- Electrode: Galan models VULKAN and OCHAG.

- Induction: SAV models SPEC and PROF.

Russian-made devices win in terms of the optimal price-quality ratio.

An inexpensive heating element boiler will cost approximately 9-15 thousand rubles., and the planned replacement of the heating element after 5-6 years his work will cost only 1.5-2 thousand rubles.

The calculation of the required power when choosing an electric boiler is carried out in accordance with the heated area of the garage, taking into account the necessary reserves in case of severe frosts.

The formula for calculating power is presented as follows: 1 kW = 10 sq. m. This means that with the area of the garage 20 sq. m. a boiler will be required for 2 kW. The reserve for severe frosts usually consists oft 15-20%, therefore, the optimal choice would be a device with a power 3 kW.

Rules for using an electric boiler in a garage

Operating rules include:

- When using electric water heatingI think it is important to insulate the enclosing structures and gates as much as possible, to avoid heat loss in the room. This will give up to 40% savings electricity spent on heating.

- It is advisable to use it in the heating system. antifreeze liquid, this will make it possible to leave the garage without heating, without draining the coolant from the system.

- It is better to install it in the garage industrial radiators in vandal-proof design for safer operation.

- It is recommended to install a fan near the radiator. to enhance air circulation and more uniform heating of the room.

Where can the device be placed?

Fire safety requirements, presented for the installation of electric boilers in garages, prescribe:

- The minimum area of the premises must be not less than 6.5 sq. m, and the height of the garage not less than 2 meters.

- It is necessary that the boiler be located at a distance from the wall not less than 1 meter. Flammable materials must not be placed around the device to avoid ignition.

- It is necessary that a barrier be made on the floor where the boiler is installed. heat-resistant durable foundation.

- The location of the boiler installation is not strictly regulated.. It is safest to place it in a part of the room that excludes unauthorized interference in the operation of the equipment. It is also necessary to have convenient access to the boiler and its piping for comfortable installation and maintenance.

Connecting the device

Heat the water in the garage heating system above 70 degrees Celsius is not necessary, so it is better to make the heating circuit closed, with natural circulation of the coolant without an expansion tank, with 2-3 larger diameter pipe extensions, leading to the heating radiators.

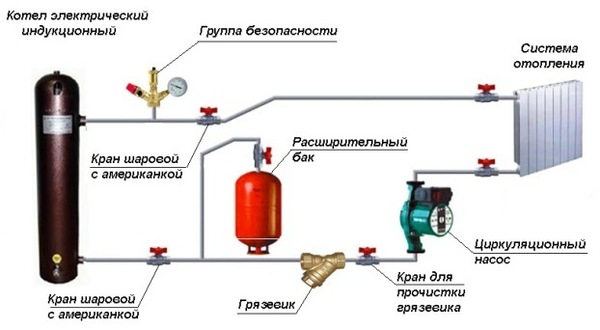

Photo 2. Diagram of a closed-type heating system using an electric induction boiler.

According to the law of thermal convection the boiler tank is installed with the heating element facing downIn this case, the heated coolant will rise up the circuit, leaving through the distribution risers, and its place is taken by the cooled coolant, coming from the circuit from below to the heating element, creating the necessary circulation in the system.

For installation of the heating system it is usually used stainless steel welded pipe diameter equal to the outlet and inlet pipes of the boiler. For welding the heating system, it is better to hire a specialist with experience in such work and his own welding equipment to ensure the quality of all connections.

Important! When connecting an electric boiler, it is necessary to follow the rules and regulations set out in SNiP, PUE, equipment instructions, and recommendations of the Electrical Supervision Authority.

Installation of a boiler with a capacity of up to 8 kW The Rules interpret this as installation of a domestic water heater.

When supplying power to the device, use a wire with a cross-section suitable for current and power.

The connection of the electric boiler to the input power supply panel is carried out via a residual current device (RCD) (except for electrode boilers), protecting against electric shock, as well as through a separate circuit breaker that protects equipment from current overloads.

The use of a grounding circuit is mandatory, connected directly to the boiler body.

Attention! When connecting an electric boiler with a capacity of more than 8 kW a three-phase power supply to the equipment is required. Connecting electrical equipment voltage 380 V Only a specialist with permission to carry out the relevant work has the right to carry it out.

Malfunctions of electric boilers

The most common problems include:

- The device does not turn off. The malfunction is usually caused by overheating of the boiler temperature sensor. If the equipment is not under warranty, the problem can be fixed by disassembling and cleaning the sensor contacts, or replacing it.

- Boiler "makes noise", the sound is similar to boiling water. This noise is a sign of air in the heating system. Installing an automatic air vent will help eliminate excess air.

- Boiler "makes noise", the sound is fragmentary and resembles a crackle. This sound usually indicates a problem with the boiler heating element, which requires replacement.

- The device does not turn on. The most common cause is the failure of some electronic element of the boiler. In this case, the help of a qualified specialist will be required.

Useful video

Watch a video that talks about the features of heating a garage using an electric boiler.

Conclusion

Heating a garage with an electric boiler has its advantages and disadvantages. The advantages are ease of use, no problems with fuel, and minus — the rather high cost of electricity used to heat the premises.

The best electric boiler models available on the market include: ZOTA 6 Econom (6 kW, 9 thousand rubles) with a 5-year warranty and three power levels, inexpensive and economical

Photo 3. Zota 6 Econom electric boiler in packaging. The device is perfect for heating garages.

Electromash EVPM-4.5 (4.5 kW, 3.9 thousand rubles), smoothly changing power in the range 30—100%; and also extremely reliable and high quality Protherm Skat 9 KR 13 (35 thousand rubles, 9 kW) with nine power levels and fast heating of a large room in 1.5-2 hours.