Creating comfort and coziness in the house: different options for heating with your own hands

Autonomous heating is a system that provides heating of air and water to create a comfortable microclimate in an apartment, private house. The heat carrier is air, gas, water or steam.

The main line is laid using a single-circuit and double-circuit scheme. Considering the ease of installation and availability of materials, many craftsmen carry out the installation themselves, observing the rules and regulations of SNiP.

Content

Criteria for choosing a heating system

Considering the ease of installation and availability of materials, many craftsmen carry out the installation themselves, observing SNiP rules and regulations.

Fuel type

Autonomous heating of a private house requires taking into account the availability of fuel, climatic conditions, and heat loss of the building. Heating with main gas is considered the most convenient solution.

Alternative - liquefied gas, supplied through a gas tank and allowing the installation of a compact chimney and a small boiler.

Replace gas:

- Liquid fuel, which allows you to automate the operation of the boiler and ensure the availability of an energy source.

- Electricity — an environmentally friendly, safe, silent heating option. Separate wiring that can withstand the power will be required 9 kW — three-phase network 380 V. A well-insulated room is heated with an electric convector or infrared emitter.

- Solid fuel, requiring provision of storage space (utility room or building) for firewood, pellets, coal, coke, and putting up with the formation of soot, carbon, and frequent cleaning.

- Combined options heating.

Equipment selection

Before you install heating, you need to choose necessary equipment.

Boiler

Boiler - main element heating system, heating coolant (water, antifreeze). Gas units are in demand on the Russian market: wall-mounted (with a capacity of up to 100 kW) and floor models, open and closed, conventional and condensing.

Autonomous equipment provides high efficiency, ease of maintenance, service life exceeding 15 yearsHowever, installation of the boiler requires obtaining permits.

Photo 1. A wall-mounted electric boiler for an autonomous heating system is installed in a non-gasified room.

Electrical equipment is used mainly in non-gasified areas. Electrode, induction, heating element boilers are compact, simple, and safe to operate. Do not require installation of a chimney, provide the opportunity to create a heating system with lower and upper wiring.

There are floor-standing, wall-mounted options, with step-by-step, smooth power adjustment. The power of the heating equipment is in the range 2–60 kW.

Liquid fuel heating devices and solid fuel models independent of external energy sources and economical. The disadvantage is the need for delivery, storage of fuel, frequent maintenance.

Method of coolant circulation

Standard heating main schemes provide for natural and forced circulation coolant.

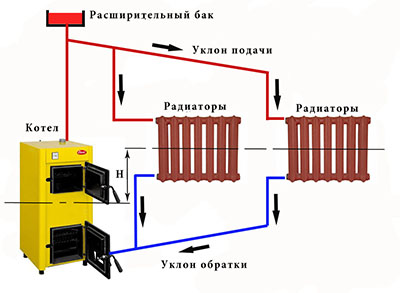

Gravity option is based on the laws of thermodynamics: high pressure is created at the outlet of the boiler, the heated liquid passes through the circuits with minimal pressure, losing temperature.

The cooled coolant returns to the heating device. The system operates exclusively on waterAntifreeze evaporates quickly.

Closed circuit includes hermetically connected pipes, radiators, expansion tank, pump. Circulation is carried out in a forced manner. When heated, the liquid increases in volume, the expansion tank valve opens, removing excess moisture.

The cooled water or antifreeze is pumped back into the boiler. Maintaining stability operation of a closed heating system Provides preset pressure limits.

Pipes

For autonomous heating it is usually used 4 types of pipes:

- Steel The pipes are characterized by strength, reliability, resistance to extreme temperatures. The disadvantage is the formation of internal corrosion, the need to use welding for installation.

- Metal-plastic The pipes have absorbed the best characteristics of two materials - a smooth base, preservation of the original characteristics, wear resistance (50 years old), absence of statics, linear expansion. The products are connected with adhesive glue, which provides strong, elastic joints.

- Copper the contours are the most reliable, the service life is long up to 50 yearsThe disadvantages are the high cost of the material and the complexity of assembling the heating main.

- Polypropylene The pipes look aesthetically pleasing but can withstand temperature loads up to 70 degrees.

Photo 2. Polypropylene pipes intended for heating systems are capable of withstanding high temperature loads.

Radiators

Pay attention to the selection high-quality and reliable radiators. The range is extensive:

- Aluminum batteries are represented by a choice of cast, extruded options. The main advantages are light weight, elegant design, high working pressure 6–12 atm. Heat transfer - 190 W.

- Steel — are characterized by high heat output, long service life. The designs are attractive in appearance and inexpensive. However, low operating pressure up to 8 atm. eliminates the possibility of installation in high-rise buildings.

Photo 3. A steel radiator with a bottom connection, installed in a niche on the wall, has a high heat output.

- Bimetallic radiators combine the characteristics of aluminum and steel. The batteries can withstand high loads and are not subject to corrosion. Working pressure 25 atm.

- Cast iron - durable and long-lasting batteries that can withstand operating pressure 5–10 atm. The designs are compatible with all types of pipelines and provide the ability to change sections, last 50 years and give off 120 W of heat.

Types of heating system

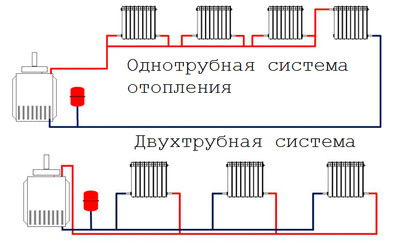

Distinguish single-circuit and double-pipe heating systems. First option applicable in rooms with a maximum area 150 m². The system provides heating, so the organization of hot water supply requires additional equipment (an indirect heating boiler with a volume of 120–2000 l). Double-circuit Boilers perform the functions of heating and hot water preparation.

Pipe laying diagram

The batteries are tied up single-pipe or double-circuit system (dead-end/radial). The first method requires higher coolant pressure during operation.

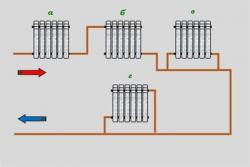

Collector the scheme provides for connection to radiators 2 pipes: at the top is the supply pipe, at the bottom is the cold circuit (return).

If the battery is short, pipes are supplied from one sideThe arrangement of long radiators involves the use of a diagonal system, when the supply pipe is connected on one side and the outlet pipe on the opposite side.

How to make heating with your own hands

The organization of a water heating system begins with the preparation of tools: adjustable and open-end wrenches, a drill, scissors, a calibrator. List of equipment for closed circuit heating is supplemented with the following materials:

- expansion tank;

- circulation pump;

- pressure relief valve;

- cranes;

- pipes with diameters of 24 and 16 mm.

Reference! The heating system consists of 2 large blocks (boiler and radiator network), connected by pipes. A wall-mounted or floor-standing boiler is used to prepare the heat carrier.

Wall-mounted boiler piping

When setting up a homemade mini-boiler room equipped with a circulation pump and a safety group, it is enough bring in and connect the supply and return pipes.

To the server the wall-mounted boiler outlet is attached tap with threaded fitting. The connection point should be easy to disassemble. If the boiler needs to be replaced, the technician only needs to unscrew the nut and disconnect the fitting.

Scheme return lines provides for vertical connection of a shut-off valve, horizontal placement of a mud filter (head down), and an additional valve with a fitting.

When passing through the heating system, the coolant gets solid fractions.

The mesh installed between the taps traps rust and dirt particles. If the filter is clogged, the boiler continues to operate, but the radiators will remain coldTo solve the problem, experts recommend cleaning the drainage mesh, after first closing two taps.

Floor device piping

A ready-made safety group or an emergency valve that releases pressure is connected to the boiler feed pipe. A tap is screwed to the left of the valve. On the right, a pipe is diverted outside the boiler to dispose of excess moisture in case of a leak. The use of shut-off valves is not permitted. between the heating boiler and the safety group.

A shut-off valve and a circulation pump are installed on the back side of the boiler. For home up to 300 m2 the household appliance series will fit 25–40, a pump is used less often 25–60 or 25–80.

The last installation option is intended for long rooms where one heating branch reaches 50 m horizontally.

According to the technical documentation, the return pump is placed at the bottom — right or left from the boiler (the arrows indicate the flow movement). The rotor takes a horizontal position. The terminal box is turned upward.

They are installed behind the pump additional crane for replacement of hydraulic machine (optional), a mud filter, then a second tap. All that remains is to connect the tee, the tap for filling the system, and the shut-off valve connecting the expansion tank.

The expansion tank compensates for pressure fluctuations in the system. The tank volume corresponds 1/10 heating systems. If the boiler capacity is equal to 70 l, volume of the radiator network — 130 l, an expansion tank with a capacity of 20 l.

Battery markings

Install batteries under windows, keeping a gap 5-6 cm from the floor, 6 cm to the window sill. The gap between the wall and the heating device, ensuring air circulation, is equal to 5 mm.

Shut-off valves or pressurization valves are installed at the inlet and outlet.

The last option allows you to use a thermal head with a range of values 0–28 degrees. The device automatically regulates the pressure in the system with a gas or electric boiler.

Attention! Connection of a solid fuel unit is not permitted. Otherwise the system will boil.

Having prepared the brackets for placing the radiators, holes are made according to the marks with a depth 12 cm. Fix the brackets with cement mortar. Per 1 m² radiator, one fastener is used. Clips, screws or nails are fixed according to the markings of the pipe laying.

Cut the required pipe size and secure with clips. The slope of the pipes is 5 mm per 1 linear meter. At the lowest point of the heating system, a tee is cut into the pipe and an adapter for the drain valve is installed.

Installation of fittings

In case of open piping requiring replacement of individual connections every 5 years, threaded fittings are used. The radial heating scheme provides for hidden placement of press fittings.

Preparation of pipes includes a number of stages: careful measurement of length, cutting the product with scissors at a right angle, leveling the deformed edge with a calibrator. It remains remove burrs with a round file.

Using threaded fittings, unscrew the connecting part, put the nut and clamping ring on the branch pipe. Until it stops place the tube on the core with a rubber seal. Align. Tighten the union nut.

For pipes of size 14–20 mm The pressing method of fastening is used. A stainless steel compression coupling is placed on the end of the pipe. The shaped side of the fitting is inserted into the pipe until it stops, gripped with a clamp of the press sleeve, and compressed with handles. One crimp is enough to create rings, similar to the shaped part of the fitting.

Water is pumped into a closed heating system through a drain valve. Pressure is created with a pump 3 bar. The air is released from the radiators and they are restored. pressure up to 3 bar. Water is also introduced into the open main line, air is released. If a leak occurs, the joints are tightened.

Installation of an autonomous homemade system in an apartment

At the project development stage, it is important to correctly select a heating source. The boiler power is calculated by the ratio 100 W per square meter of area. The type of wiring is determined by the parameters of the housing.

For small apartments A single-pipe system is quite suitable; for spacious rooms, a two-pipe system with bottom wiring is traditionally selected. Closed circuit preferred with forced circulation.

Gas boiler type depends on the presence of a house shaft. It is possible to install a simple heating device with an open combustion chamber. In the absence of a chimney channel, a turbine generator with a closed chamber and a coaxial pipe passed through the wall is used.

Detailed work plan includes installation of a boiler, replacement of batteries, supply and outlet pipes (it is forbidden to touch the risers). Residents of apartments also implement individual heating using the underfloor heating system. If there is no confidence in the quality of the interfloor overlap, the ideal option would be to lay pipes on wooden joists finished with laminate.

So that the heat supply organization stopped charging for energy consumption, the riser is insulated. All work is carried out after a written refusal from the central heating supply. The boiler is connected to the gas or electric main by the energy supplier.

Important! Autonomous heating in apartments is allowed no higher than the 10th floor!

Replacing radiators

The process of replacing radiators in an apartment is associated with the correct choice of fasteners. Sectional batteries are fixed with angular, pin brackets.

The last option is used. on plaster, brick and concrete walls. Corner fasteners are suitable for wooden coverings. Fasteners are supplied complete with radiators, dowels or screws.

Assembling knots with their own hands, masters gaskets are placed in advance, plugs and taps are tightened. They make markings on the pipes, secure the corners and electronics.

Old heating devices are connected to pipes by means of coupling - a thread with a screwed coupling and a fixed nut. The parts are unscrewed by hand, after being treated with an anti-corrosion compound. The battery is cut off with a grinder.

The new radiator is being secured together with pipes or separately. The second method involves unscrewing the lock nuts, cutting off the old batteries, and installing new ones. The main criterion when choosing radiators is the dimensions corresponding to the devices of the previous heating system.

The further action plan includes:

- Marking of points for mounting brackets (minimum 3).

- Installation of fastenings into the wall with dowels.

- Putty with cement mortar.

- Accommodation packed in protective film batteries.

- Connecting the radiator to the upper and lower pipes heating system.

- Screwing on the air valve. The outlet part of the shut-off valve is installed strictly to the ceiling.

All that remains is to remove the protective film and test the batteries. under pressure of 3 atm.

Attention! Planning a radiator replacement together with pipes (first method), the contours are carefully cut off at the turn towards the neighbors.

Useful video

Video instructions for creating an autonomous heating system with cast iron or aluminum radiators.

Recommendations from experts

When preparing to install a heating system yourself, assess your strengths and financial situation sensibly. make a thoughtful plan of actionIf it is not possible to do the work yourself, Use the services of construction companies.

Comments

Detailed planning of the work includes the following: installation of the boiler, replacement of the battery, supply and discharge pipes.