A little skill and everything will work out! How to fill the coolant into the heating system

To make heating your home cheaper, you can do some of the work yourself.

Filling the system is carried out: after repairs; after draining the system for the summer; when replacing the coolant.

Each type of heating system has its own nuances, so filling can occur differently.

Content

- Frequency of replacement of coolant

- Types of coolant for filling into the heating system

- Preparatory work before pumping thermal fluid

- Filling the heating system

- How to add water to a heating system

- Types of pumps for pumping liquids

- Coolant drain technology

- Useful video

- Is it possible to handle the refueling yourself?

Frequency of replacement of coolant

If in apartment buildings the coolant is drained annually, then in private buildings it is not necessary. It should be assumed that the water that has already circulated in the system for a season, is prepared:

- does not contain oxygen;

- as a result of prolonged contact with internal surfaces received inertia, which became a guarantee of the preservation of the contour materials;

- all salts and chemical compounds that, when heated, turn into sediment and scale, have already fallen out, and the water became adapted to circulation without chemical activity.

If there is no danger of the system freezing, it can circulate one more or even two seasons. To determine the need for replacement, the coarse filter is checked - if it is relatively clean, then the water does not need to be changed.

As for antifreeze, the quality composition changes according to technology once every 5-7 yearsHowever, in practice it has been used much longer.

Types of coolant for filling into the heating system

Several types of heat carriers are used for heating systems.

Water

Cheap universal coolant:

- if you pour in distilled water, there will be no scale or sediment;

- does not change properties when in contact with internal surfaces;

- safe for people;

- can spin in the system almost infinitely.

Flaws:

- When frozen, it expands and destroys pipes., so in cold climates you will have to buy antifreeze.

- Metal pipes begin to rust.

- When using tap water, a large number of salts crystallize, therefore you'll have to buy distilled water. If the water supply is filled, regular cleaning of the main units and, if possible, pipes from salt deposits is recommended. The process is labor-intensive and requires special reagents.

Antifreeze

It is a water solutions of ethylene glycol or propylene glycol with additives.

Photo 1. Antifreeze for heating systems from the manufacturer Termagent. Withstands temperatures down to minus 30.

- Only approved for use in heating systems antifreeze with a composition developed for this purpose. This liquid cannot be used anywhere else.

- Freezes at temperature from -30° to 60°C.

- Antifreeze containing ethylene glycol is toxic.

- Safe for humans heat carrier with propylene glycol It is expensive and requires replacement every 5 years.

- The new formulation that is being offered on the market contains potassium acetate and formate. It is suitable for areas with a moderate climate - it freezes at a temperature of below -5°C. In terms of cost, it is a more affordable option.

The right choice of coolant requires careful attention and consideration of certain factors:

- Sometimes the boiler operating instructions specify the permissible types of liquid and others cannot be used. Some foreign manufacturers exclude the use of antifreeze altogether — warranty obligations are cancelled.

- The material from which the main units and pipes are made is the system must be made of chemically resistant pipes and componentsAntifreeze is incompatible with galvanized iron because it changes properties upon contact.

- Certain types of compositions they heat up poorly and give off heat, if they are used, the system is designed with this in mind.

- Coolant should not contain toxic or poisonous substances.

- The most efficient fluid for the system has low viscosity.

- Some types of coolant are intended For industrial use only.

- Cost of coolant And its permissible service life.

Preparatory work before pumping thermal fluid

Before filling the heating system, it is necessary to carry out preparatory work.

Pressure testing

Pressure testing is a serious part of commissioning work, which is carried out before the first start-up of the system, as well as before each heating season. This is the name of the hydrodynamic test of the system under conditions that are more complex than the subsequent actual load. This is a test of the strength of the pipeline, all connections and units, as well as the entry and exit points into the building, the underfloor heating system, the equipment and the operability of the boiler rooms.

The principles of implementation are regulated by SNiP:

- The temperature in the building should be above 0°C.

- Selection of the test pressure must not exceed the limit values, specified by the manufacturer.

- The value of the pressure test must exceed the working pressure. by 50%.

- In private homes, the pressure testing is on average in the range 2-6 atm.

- Systems in older homes are tested with lower values, cast iron radiators also set a limit to the maximum value - no more than 6 atm.

- When selecting the optimal value of the test pressure It is important to use technical documentation for pipes and equipment, one should proceed from the permissible maximum for the weakest link in the system.

- Water testing is being carried out, even if antifreeze is poured into the system, pressure testing with a working solution is done second.

Parameter control

Only a specialist with the appropriate knowledge and experience can perform proper pressure testing. Checking and monitoring parameters requires special equipment.

Recommended parameters:

- above workers one and a half times, not less than 0.6 MPa.

- not new networks are tested under pressure 1.25 higher than working, not lower than 0.2 MPa.

- in private houses up to three floors heating works under pressure no more than 2 atm.

- in five-story apartment buildings 2-6 atm

- in buildings with more floors 8 — 7—10 atm.

These values are adjusted on-site based on the state of the system components..

In private homes, fittings, radiators, etc. are often in better condition than in apartment buildings.

According to the rules, such work can be carried out in apartment buildings once every 5-7 years.

Filling the heating system

The methods of filling an open and closed heating system differ.

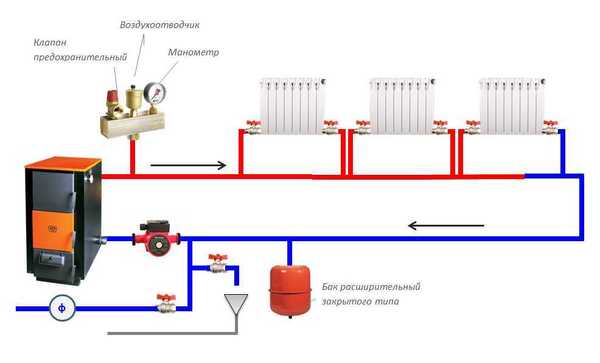

How to fill in a closed

The closed system is equipped with sealed expansion tank, which is set arbitrarily.

Attention! It is not recommended to use the upper tier of the system for filling the coolant. In this case, the air comes out through the coolant layer, saturating it. When heating along the entire circuit air pockets are formed.

The optimal option is to supply the coolant through the lower valve:

- from the water supply;

- from a container, well using a pump.

Photo 2. Scheme of a closed heating system. A sealed expansion tank and a pump are installed in it.

The process itself is carried out at the beginning of the heating season or after repair work.

High-quality antifreeze can be refilled once every 5-6 years.

If the liquid is not supplied from a water supply, a pump will be required. The source is a well or a tank. Filling process:

- It is better to fill the system with two people, then it will be easier to control the pressure.

- The coolant is pumped in with the heat source turned off.

- All shut-off valves are opened, remains closed only drain.

- The radiators are also blocked, except for the most distant ones in each branch.

- The coolant supply is connected: the circuit, boiler and tank are filled.

- From the beginning of the process, air release is controlled: it must exit through the safety group valve and the drain at the highest point of the line.

Important! It is recommended to set the security group for a system with any type of boiler and fuel type.

- The radiators are opened, starting from the first one from the boiler. The taps are opened, air is released through the Mayevsky tap, after filling the radiator is closed again. This process is repeated with all radiators of the branch.

- When the batteries are full, the accumulated air is released from the circulation pump.

- Next, the heat source is activated and the pump is turned on at the same time.The system is being bled - without radiators.

- When the pipes are hot enough, the taps on each radiator are opened. In this case, it is necessary to once again check the air outlet from each one.

- If everything is done correctly, the pressure stabilizes and is no more than 2 Bar.

- The process is repeated for each branch., lastly the coolant is poured into the warm floor.

If the heating is designed with a collector, then branches are filled separately, air is released through the manifold valves.

Attention! In case of a branched structure, pumping and heating of the system is carried out only after filling in all parts.

The process takes a lot of time and requires attention. If key points are missed, air may remain in the system, which will subsequently cause problems with the heating system.

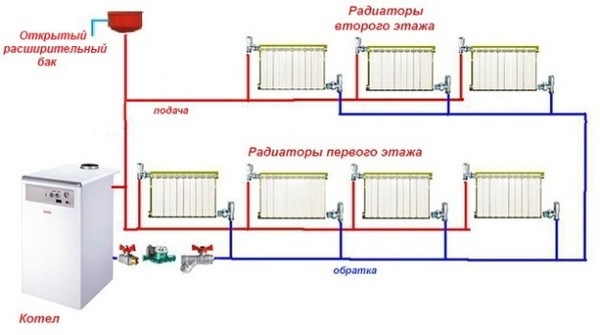

How to upload to open

This is an open container with a lid, which is also a convenient entrance for water to enter the system. It is filled with a regular bucket or a pump is attached. The difference in filling is in the pressure in the circuit: it is equal to the usual atmospheric. The coolant contacts the environment - an expansion tank is installed at the highest point of the circuit.

Photo 3. Scheme of an open heating system in a two-story building. The scheme is filled with a coolant through a special tank.

Filling process:

- If a pump is used, then you will need a large container for supplying certain volumes.

- The water is poured in gradually, with breaks — so the air will be able to escape. If the pump is turned on, the pressure in the circuit should not exceed two atmospheres. The water is stopped when the expansion tank itself begins to fill.

- Next, air is released from all radiators and system components. To do this, open the valves or Mayevsky taps until liquid appears.

- Water is then added to the system. The air is mostly removed by itself through the expansion tank, after the heat source is started this process intensifies. In an open system the problem of air locks is not as acute as in a closed one.

Evaporation occurs from an open tank, so From time to time you will have to add water.

The outline is filled from below, if there is a corresponding connector.

How to add water to a heating system

The coolant is added differently to closed and open heating systems.

In closed

The system must maintain constant pressure., which depends on the total volume of coolant in the circuit.

During operation, the amount of liquid decreases, so the circuit should be regularly replenished. through special make-up valves, located at the point of lowest pressure - in front of the pump.

Photo 4. Make-up valve for the heating system. It can be used to add coolant when the heating circuit is closed.

In the open

In an open system, the problem of coolant leakage is more pressing - the evaporation of hot water from the tank requires constant monitoring and replenishment of the system.

The liquid is simply poured into the tank.

Types of pumps for pumping liquids

Filling an open system is not a problem in terms of equipment - a regular bucket is enough. To speed up the process and make it more convenient, a a hand pump or device powered by electricity.

A closed system, on the other hand, can only be filled with a pump, the coolant is supplied under pressure.

Any pumps are suitable for these purposes., there are no specialized ones for pumping antifreeze into the heating system.

Vibrating

Vibrating submersible pumps are completely submerged in liquid. This is how the popular "Baby", which is used in wells and boreholes. This device is quite suitable for pressurizing up to 4 atmAnother useful thing for the system is that this pump is equipped with filters.

Drainage

This is also a submersible device, but there is a difference from the previous type of device: the unit passes inclusions, the maximum size is indicated in the technical data sheet.

By using such a device, measures are taken to prevent foreign particles from entering the system.

When selecting a container for the liquid being pumped, Another feature of this type of device is taken into account: a float mechanism that switches off the unit if there is little liquid left.

Self-priming centrifugal

These pumps operate while remaining on the surface. — a hose is immersed in liquid. Due to their high power, they are used to fill the system and for pressure testing.

Manual piston

A convenient, economical unit with a tank, equipped with a pressure gauge, which allows you to control the pressure. Requires significant physical effort.

Coolant drain technology

- To drain, you will need a hose that connects to the boiler pipe. The second end is placed in the sewer or a separate container.

- The boiler switches off.

- The hose is connected to the return valve, located under the boiler (if it is not there, then the location is indicated in the technical passport).

- The valve opens, and the liquid drains, then closes again.

- After this, the system is filled with air., for this purpose the Mayevsky taps are opened at the highest point of the circuit. Then the drain is performed again.

- Now they're letting the air in again., but this time all available Mayevsky taps are opened. The liquid is drained once more.

- Finally, the hose is reconnected from the return valve to the supply valve.In this case, the hose is positioned as low as possible in relation to the tap.

Important! It is impossible to drain the underfloor heating system in this way, to drain this branch you will need a special compressor.

Useful video

Watch the video to learn how to properly fill and start your heating system.

Is it possible to handle the refueling yourself?

The services of professionals in solving problems with heat supply cost a lot of money, therefore You can do this yourself. If you approach the issue carefully, avoid pressure surges during filling, and follow the technology, the problem will be solved.