The most important stage when starting the heating! How to properly fill the heating system in the house

Filling the heating system is a crucial stage in starting the operation of the entire installation. The further integrity and service life of the heating system depends on how competently it is carried out.

This process begins with the selection of a substance that will circulate in the pipes.

Content

What does the choice of coolant depend on?

There are gaseous and liquid heat carriers. Liquid, in heating structures - the most common.

The choice of a particular liquid directly depends on the operating conditions., poured into the system.

In cold winters there is a risk of water freezing, which leads to burst pipes.

The solution may be liquids that do not freeze at low temperatures, such as antifreeze.

Important! Choose a coolant even at the design stage of the heating system — the type of OS design and the boiler parameters depend on this.

When choosing a coolant, pay attention to 3 factors:

- Heating operating mode and conditions throughout the year. If you plan to heat the system 24 hours a day without interruptions using a gas boiler in winter, you can add water, even in harsh winter conditions. But if the owners are often absent, or use an electric boiler, and there are power outages in the region, then all this is a signal that you need to add antifreeze to the OS.

Attention! When using antifreeze and other “antifreezes”, the system is sealed more tightly because coolant leaks are unsafe.

- The maximum heating temperature of the liquid when working with a specific boiler.

- Acceptable frequency of coolant change. Antifreeze is completely replaced once every 5 years. Some manufacturers indicate a 3-year periodicity.

When choosing a liquid heat carrier, specialists It is recommended to use the following criteria:

- Safety. The liquid must be non-flammable and non-toxic to living beings when evaporated.

- High thermal conductivity. When the carrier maximally accumulates heat from the boiler to release it in the radiators.

- Wide range of work. The wider the distance between the extreme points of boiling and freezing, the better.

- Inert to the chemical composition of pipes and gaskets. The coolant must not react with the material of the heating system elements.

- Anti-corrosion properties. The coolant must not cause corrosion and leave a large amount of scale in the pipes and channels of the boiler and the entire system.

- Viscosity and flow properties must correspond to the readiness for additional expenses. It should be taken into account that for liquids with increased viscosity and decreased fluidity, more powerful pumps are installed in the heating system.

- Stability of chemical composition. The coolant must not decompose into its components over time or under the influence of temperatures, must not produce sediment and must not change its characteristics: heat capacity, fluidity, viscosity.

- Speed and efficiency. Ensure fast start-up of the CO and transfer the maximum amount of heat in a minimum amount of time.

- Cost-effectiveness. The cost, taking into account its availability and the time frame for its complete replacement in the system, must be economically justified.

Types of coolants for heating systems

Let's look at the most popular liquid heat carriers that have proven themselves to be the best.

Water

Statistics say that water is the most widely used heat carrier in private housing construction (up to 70% of cases). This is due to its cheapness and availability: you can collect it from a water supply system, a well, or a river. True, such water also requires costs, if not financial, then labor and time. Because it will need to be softened and purified. Otherwise, corrosion, limescale and silt deposits guarantee premature failure of the heating system.

Water is brought to condition in three ways:

- By boiling water — the process for large volumes is complicated and does not completely remove all salts and substances from the liquid. And these are deposits on the pipes.

- By dissolving softening reagents in water - soda ash or sodium orthophosphate.

- Filtration of water through washable or replaceable filters (with layers of quartz, activated carbon, expanded clay or anthracite).

It is much easier to buy distilled water. In small 5-liter packaging for drinking it costs about 16 rubles per liter. When purchasing a wholesale batch of distilled water (depending on the area of the OS, it will need to be from 80-100 liters and above), significant discounts are possible.

Photo 1. Bottle of distilled water Artik Yeti for heating system. The package contains five liters of liquid.

The heat capacity of water is the best

No other liquid comes close to water in terms of heat capacity characteristics - it has no equal here. At the same time, water has a high density. With an average temperature difference of 20 degrees between the extreme points of the OS, a liter of water during cooling transfers about 23.5 Watts heat energy.

Viscosity

As the temperature drops, the viscosity of water increases rapidly. The thermometer drops below zero - water forms crystalline structureThe power of frozen water is great - it easily breaks metal and cast iron pipes and radiators. Therefore, even a short stop of water heating in winter threatens a serious emergency situation. There is no way to bypass this property of water.

Corrosive activity

Water aggressive to ferrous and some non-ferrous metals, it is a strong oxidizer in itself, because dissolved oxygen is present in its formula in any case.

To reduce the effects of corrosion apply the system deaeration procedure (removal of excess oxygen and carbon dioxide). It is carried out with the help of smart equipment by specially trained engineers.

Conduct anti-corrosion prevention using inhibitor additives that are added to the water. Together with them sometimes surfactants (surface-active additives) are added, capable of dissolving old scale and rust in the system.

Toxicity

The environmental friendliness of clean water without chemical impurities is an undoubted advantage as a heat carrier in the system. It will not poison anyone with toxic fumes. It will not catch fire or explode even if there is a leak.

Antifreeze

In Russian it is literally translated from English as "non-freezing". Prices on the market are very diverse and start from 40 rubles per 1 liter of ready-made solution and from 80 rubles for concentrate. The most common ones are based on ethylene glycol.

Photo 2. A 10 kg bottle of antifreeze for the heating system. The substance can withstand temperatures down to -65 degrees.

Heat capacity of antifreeze

Even the best antifreeze is always inferior to water in terms of thermal characteristics. Its heat capacity 15% lower. This reduces the efficiency of the system and requires the installation of more radiators.

Viscosity

The viscosity of antifreeze is always higher than that of water. Therefore, for its normal circulation through pipes More powerful pumps are needed. For the same reason, antifreeze only requires a closed heating circuit.

The temperature of transition to a dense state of antifreeze is significantly lower than that of water. And even when forming a crystal lattice, antifreeze does not become hard as ice, but acquires a gel-like consistency.

The advantage is that the gel will not expand and will not break the pipes, the disadvantage is that its fluidity will be minimal until it warms up. And to drive it through the pipes after stagnation, you need the most powerful pumps. Craftsmen dilute strong antifreezes (withstanding temperatures up to minus 60 °C) with distilled water and obtain optimal fluidity and “non-freezing” properties at a temperature up to minus 30 °CFor most regions this is sufficient.

Corrosive aggressiveness

Ethylene glycol based antifreeze needs additives, preventing corrosion of the metal circuit.

But there are metals that are not allowed to come into contact with ethylene glycol (galvanized coating, For example).

In addition, such additives reduce the formation of foam, which this antifreeze is prone to at high temperatures. Foaming can cause gas locks in the circuit.

The sensitivity of ethylene glycol antifreeze to high temperatures is not just foaming. It is the decomposition of the composition, on the one hand, on a solid insoluble precipitate, which blocks everything in its path, and, on the other hand, for aggressive acids, corroding the contour with rust.

Toxicity

Most antifreezes have contains toxic substances, harmful to all living things. A Ethylene glycol is generally poison. Due to this, the slightest possibility of leakage or evaporation of such a coolant cannot be allowed. And this is a rather difficult task.

Although the viscosity of antifreeze is higher than that of water, its ability to seep through seals is an order of magnitude greater! Antifreeze requires replacement of gaskets, resealing and complete packing any connections in the heating circuit. Not every gasket material is suitable in the case of aggressive antifreeze reagent.

Attention! Toxic antifreezes completely excluded for use in dual-circuit heating systems due to the possibility of liquid entering the hot water system!

Due to toxicity, antifreezes of this type more often used in technical rooms: in warehouses, in garages.

Propylene glycol

Antifreezes based on this substance are used in residential premises because they are considered environmentally friendly. Prices for it start at 100 rubles per 1 kg of liquid with additives, can reach up to 300 and above.

Photo 3. Packaging of Hot Stream propylene glycol for heating systems. Withstands ambient temperatures down to -60 degrees.

Heat capacity

Its heat capacity is inferior to water, but still higher than other antifreezes. This the liquid gives a good efficiency CO also due to the "lubricating" effect on the walls of pipes from its solutions. This reduces resistance during circulation and increases heat transfer.

Viscosity

The viscosity here is the same story as with other antifreezes. This is viscous in structure a liquid with low fluidity that turns into a gel at low temperatures. Requires powerful pumps to circulate the circuit.

Corrosive activity

This indicator for the liquid is lower than for most aqueous salt and alcohol solutions. On the one hand, this is reduces the requirements for the grade of metal of the contour parts. However incompatibility with zinc Propylene glycol remains at the same level as its toxic counterpart, ethylene glycol.

Important! Propylene glycol is strictly prohibited to use. in a contour with galvanized parts!

Toxicity

The substance is even used in the food industry as an approved food additive and as a raw material for containers. This liquid will not cause any upset if it gets into drinking water.

Reference. Propylene glycol allowed to be used in dual circuit systems heating and water supply.

Special solution

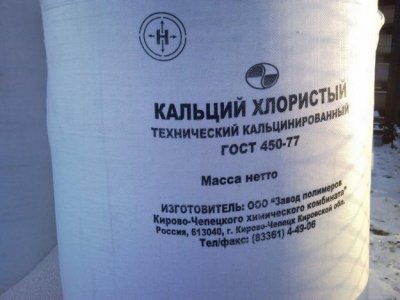

We are talking about water saline solutions, such as, for example, an aqueous solution of calcium chloride.

20% solution such brine freezes at a temperature minus 18 °C, 30% solution - at minus 48 °CThe low cost of producing such a coolant is obvious: 1 kg calcium chloride is worth from 5 to 8 rubles.

The advantages of brine include not only its availability, but also high heat capacity characteristics. Just like propylene glycol, this brine is a food additive and is considered environmentally friendly.

The big minus of such a coolant is its high corrosive aggressiveness, and also complex recycling process. When using brines, the use of parts made of ordinary steel or cast iron in the circuit is under no circumstances permitted. Only plastics and stainless steels.

How to fill the system correctly with your own hands

The first thing you need to do before filling the heating system is to calculate the required volume of heat transfer fluid. This is done simply: add the volumes specified in the technical documents:

- Pipes and radiators.

- Boiler.

- Expansion tank.

Selecting a filling pump: electric or manual

If you are pouring antifreeze or distillate, you will need a pump that will pump the liquid coolant from the reservoir (bucket, boiling tank) into the circuit. The pump can be used both electric and manual. Manual is good when there is no electricity and you need to fill the gas heating system.

Photo 4. Hand pump from the manufacturer Instan for pumping coolant into heating systems.

Submersible pressure testing hand pump It is convenient not only to fill the coolant into the system, but also to pressure test it: conduct a leak and strength test. The only downside to this pump is the long and labor-intensive pumping process.

Flushing, pressure testing and correction of defects

Before pumping, if we are dealing with a change of liquid - The used coolant needs to be removed. To do this, open the drain valve. If the coolant does not flow out well, use a circulation pump.

When changing the coolant The heating circuit needs to be flushed. An exception to the rule is glycerin antifreeze. When using it, flushing is not required.

During the pressure testing process the system tested for strength and tightness, pumping water under pressure, exceeding the norm by 2-3 times. They monitor the pressure gauge: if the pressure holds, then everything is OK with the sealing. But if it drops, you need to look for leaks and correct the shortcomings.

Important! Before the pressure testing procedure Cover the floors with waterproof polyethylene!

Filling the coolant, bleeding the air and starting the heating

This stage is carried out in the following order:

- Open the taps: on the expansion tank, on the feed and return from the boiler, on the circulation pump and valves on all radiators. And also on the feed and return of the collectors, if they are present in the system.

- Open the automatic air vents (if any).

- Mayevsky taps, vice versa, - close.

Photo 5. Mayevsky tap on a heating radiator. Before pouring the coolant into the system, the tap must be closed.

- Fill the system (either with a hose from the water supply, or with a pump from a bucket or barrel) through the appropriate tap. At this time, you will hear the whistle of air being forced out of the system. We pump up to the indicator on the working pressure gauge in 1.5 atmospheres. After this, stop downloading.

- Next, carry out the following procedure for all radiators: open the Mayevsky tap and wait until only water comes out of it after air and water. This is a sign that it is time to close it. After this procedure, the pressure usually drops.

- Refill the system with coolant up to the working pressure level at 1.5 atmospheres.

- Bleed the air from the circulation pump and run it for 15 minutes. Then bleed the air out of it again. If water comes out, everything is fine.

- While the pump is running, check the air vents and Mayevsky taps again.

Attention! Air may still be escaping from the system. 3 weeks, so be prepared to monitor the operating pressure and refill the CO every time up to 1.5 atmospheres.

Now we need to turn on the boiler. with the circulation pump running (required!) first at 40 °C warming up. Check how the radiators heat up on the entire circuit. If they don’t heat up, you need to bleed the air again. And only when the entire system shows a working condition, increase the heating of the boiler up to 60-70 °C. Keep the system in this mode for a while longer. 3-4 hours, until you are sure that it is fully functional.

How to fill the heating system in apartment buildings

Filling the heating system in an apartment building occurs in the following order:

- Water is slowly introduced into the system. The feed pumps are turned on at the lowest power so that filling occurs gradually.

- Typically filling occurs through the return line. This option allows you to avoid the formation of air locks in the heating system.

- Next, you need to get rid of any remaining air in the system. This should be done using air collectors, which are located in the attics of a multi-story building. You need to lower the starting valve on them and wait until the characteristic whistle stops. This will signal the absence of air in the system.

Useful video

Watch the video, which explains how to fill the heating system in a private house step by step.

It's better with a professional

Of course, you can fill the CO and launch it yourself. But this procedure is a test and potentially an emergency. Therefore It is wiser to entrust it to professionals - heating experts, paying a one-time sum. This is much better than urgently investing in repairs of possible damage on the eve of the heating season.

Comments