Without them, the system will not last long! Three-way valves for heating: purpose, types

You are viewing the section Three-way valve, located in the large section System components.

Three-way valve - shut-off and control valves for redistribution of heat carrier in the pipeline of the water heating system.

The installation of three-way valves in the heating system is necessary to maintain the stability of the entire structure.

Content

- Purpose

- The device and the principle of operation, how many positions does the device have

- What is a ball valve, what is it for?

- Types of heating taps

- Classification of products depending on the type of construction

- Selecting a three-way valve

- Recommendations for selection

- Installation of a three-way valve, device designation on the diagram

- Useful video

- Advantages of the device

- Comments (1 opinion)

Purpose

According to GOST 10944-97 A three-way valve (KRT) can be used to regulate and completely stop the flow of coolant in single-pipe heating systems at the closing sections.

Conditions for using reinforcement:

- Water temperature up to 150 °C.

- Working pressure up to 1 MPa.

- Ambient temperature from 5 to 45 °C.

The device and the principle of operation, how many positions does the device have

The crane has a T-shape and its design includes:

- Body (brass, bronze, cast iron or carbon steel).

- Three pipes.

- Locking device.

One of the pipes is intended for connection to the hot water pipeline, the other - to the cold water pipeline. The position of the valve (lever) determines the action performed: splitting the water flow into two outlets or combining hot and cold water.

Important! Device redirects the flow rather than blocking it. You can completely block only one of the pipes, or half-block both at the same time.

Depending on the shut-off device that blocks the flow, taps are divided into: ball and rod.

What is a ball valve, what is it for?

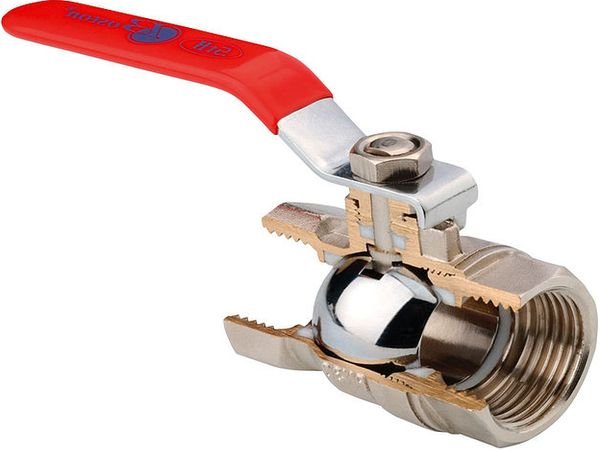

Locking element of the unit - a ball made of polished stainless steel, which is located in the body. A ball with a through hole is placed inside a seat made of Teflon sealant.

Photo 1. Ball valve in section. Inside the body of the product there is a stainless steel ball.

To adjust the flow, rotate the lever or handle of the tap, which changes the position of the ball. Due to the smooth rotation of this element, the flows are mixed, which allows you to get the desired water temperature.

With active use of the device, the Teflon seals wear out, which leads to a loss of tightness. However, this The option is suitable for use in a home heating network, since ball models are more resistant to temperature changes.

Types of heating taps

In most cases, the fittings are additionally equipped thermostat or electric drive. This allows you to maintain the desired temperature automatically.

Three-way with thermostat

A tap equipped with a thermostat, will maintain the required temperature regime. The thermostat does not change the existing power of the heat source, but allows you to regulate the temperature in a specific circuit to create comfortable conditions in the room.

Attention! If cast iron radiators are installed in the room, the thermostat will not work effectively, since cast iron has high thermal inertia. It is advisable to install thermostats for steel and bimetallic radiators.

The temperature of the coolant is controlled by a head with a temperature sensor, filled with a heat-sensitive liquid.

Photo 2. Three-way valve with a thermostat. At the top of the product there is a lever for adjusting the temperature.

As the coolant temperature increases, the liquid expands and rises into the reservoir, which also expands and puts pressure on the rod. Under the pressure of the rod, the branch pipe opens and cold water flows into it. As the temperature decreases, the rod rises and hot water flows through the left branch pipe.

Thermostats are divided into mechanical and electronic. The first option is more unpretentious in operation, simple and reliable. The electronic thermostat is distinguished by the accuracy of settings and multifunctionality.

Three-way with servo drive

The device can be controlled manual and automatic. Manual - used for forced temperature regulation. For automatic control, an electric, pneumatic or hydraulic drive is used.

Reference. In domestic heating systems, taps with an electric drive with a power of 12 V and 24 V.

Models with an electric drive are the most efficient, as they regulate the temperature of the heat flow as precisely as possible.

Electromagnetic motors, installed on three-way valves, are called servo drives. Unlike conventional motors, their shaft does not rotate, but only turns a certain degree.

Photo 3. Three-way valve with servo drive. Such a device must be connected to the electrical network.

The controller sends a signal to the servo drive, after which the motor moves the ball or rod to a different position. Motors allow you to fully automate the operation of the heating system.

Classification of products depending on the type of construction

Depending on the design and functions performed, locking mechanisms are divided into 2 types:

- Mixing.

- Distribution.

Mixing

They have two inputs and one output. The following tasks are performed using cranes:

- Redirect flows coming from different pipes.

- By mixing hot and cold water, the required temperature of the coolant is set.

The device allows you to create conditions under which the coolant is constantly used when the coolant source is completely shut off.

It is recommended to install it in heating systems with boilers that provide heat to pressureless collectors, and the circulation of the coolant in the system is carried out using a pump. It is also used in "warm floor" systems.

Distribution

Since the device has one input and two outputs, there is no mixing of flows, but splitting one stream into two.

The valves inside the pipes operate alternately: one of them opens the passage, the second at this moment closes the main line. The working medium enters the shut-off mechanism through one branch pipe, and exits through two.

Cranes of this type used in boiler systems, for piping water heaters, as well as for redistributing heat to several rooms, in hot water supply systems.

Selecting a three-way valve

The main parameters that are important when choosing:

- Nominal diameter.

- Bandwidth.

- Connection type.

- Control.

Nominal diameter

This is an indicator that means average internal diameter of pipes, corresponding to several external diameters of the pipeline. The true internal diameter of the pipe in most cases does not coincide with the conventional one, but is as close to it as possible.

The outer diameter of a steel pipe corresponds to a certain nominal diameter. For example, for a steel pipe Ø 26, 8 mm a crane is needed with DN 20 mm.

Bandwidth

Information on the capacity of the heating system indicated in the technical documentation for the heating boiler.

Taking this data into account, you can select a faucet.

If the device's capacity is less than necessary, this will lead to increased pressure, increased load and rapid wear of the mechanism.

Connection type

The connection by which the locking mechanism is fixed to the pipe can be:

- Flanged — installed on the pipeline system using a special bolted connection. Rubber or steel rings provide tightness.

- Coupling — connected to the pipeline using couplings with internal threads. Tightness is ensured by fluoroplastic tape, mastic or sealant.

- Nipple — the ends of the locking mechanism have external threads and are secured using a nipple and union nut.

Control

It is preferable to opt for a device equipped with a servo drive, which can be of three types:

- Open — in the absence of voltage, the coolant passes through an open channel.

- Closed — the coolant passes through the channel only in the presence of voltage.

- Universal — the device can operate in either of two positions.

The choice of device type depends on what position is it in most of the time. Thus, for cold regions of the country, an open-type servo drive is recommended, and for warm regions, a closed-type one.

Recommendations for selection

Depending on future operating conditions, the device is selected as follows:

- For connecting underfloor heating In a room with a small area, you can use a three-way valve with a thermal head.

- For heating system, in which several circuits will be involved, a three-way valve with a hydraulic or pneumatic drive will be suitable.

- Into a complex multi-circuit system locking mechanisms with a servo drive are installed. Such a system is divided into several zones, each of which is equipped with a separate mixing unit.

Installation of a three-way valve, device designation on the diagram

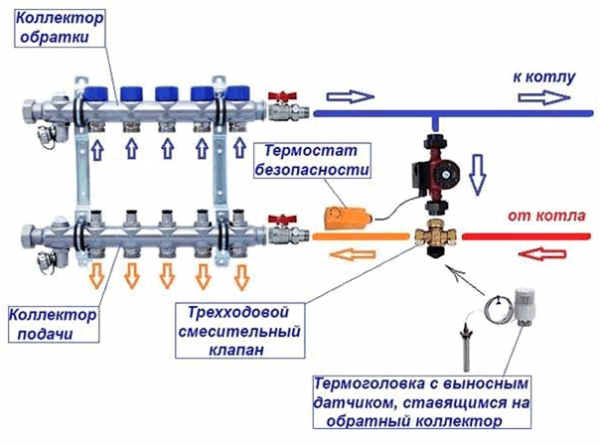

If cooled coolant enters the inlet pipeline, it can cause condensation, which will put the heating boiler out of order. Installing a valve separately for the heating boiler will help prevent this. In a multi-circuit heating system, the mechanism installed on the pipeline entering the boilerIn a multi-circuit system, in which there is no collector unit, they install several three-way valves.

Photo 4. Diagram with the installation location of the three-way valve in the heating system. The device is installed next to the boiler.

In a heating system that includes only underfloor heating, the device is installed on the return flow line of the coolantIf its temperature is sufficient, the amount of "return" will be reduced. In this case, the device works to regulate the strength of the flows.

Important! During installation, you need to navigate in the direction of the arrows, located on the body of the device, indicating the flow of the stream.

Example of installing a tap in a "warm floor" system:

- Temperature of the coolant in the system 65 °C (it is necessary to obtain a heat carrier with a temperature for the floor 30 °C).

- The shut-off mechanism is installed in such a way that the coolant with a higher temperature is mixed with the flow of water from the return line, which allows water of the required temperature to be obtained at the outlet.

Useful video

Watch the video to see exactly where to install a three-way valve.

Advantages of the device

A three-way valve, which is included in the heating system, provides the following advantages:

- When installed in a "warm floor" - maintains a comfortable floor temperature and saves energy.

- Supports optimum temperature at the boiler pipe inlet, which prevents the formation of condensation.

- Opportunity creation of a multi-circuit heating system in a private house with maintaining the required temperature in each of the circuits.

Comments