The subtleties of maintaining a comfortable thermal balance: how does a three-way valve for heating work?

A three-way valve is type of shut-off valves.

It is designed to mix or redirect flows to achieve the desired coolant temperature.

The devices are used for creation of separation or mixing units heating mains regardless of their type and temperature conditions.

Content

- Three-way valves for heating: what are they?

- Varieties by the principle of operation in the system

- Four criteria for choosing a thermostatic mixing device

- What does the cost depend on?

- Installation and connection: how to install it?

- General recommendations

- Which manufacturers can be trusted?

- Useful video

- Conclusion

Three-way valves for heating: what are they?

The thermal valve prepares the heat carrier with the specified parameters and is used:

- to control the underfloor heating system;

- for the purpose of regulation and control of heating in rooms of the same building, including between floors;

- to create heating systems in several separate buildings.

The devices regulate heat emission by changing the quantity, not the temperature of the coolant. Thanks to this, it is possible to heat rooms of different intensity without changing the size of the radiators.

Design

Three-way valve - metal tee with three branches, equipped with an adjustment washer on top. In the mixing tap two inlet ports and one outlet port. In the dividing - two outlet pipes and one inlet.

The body is made from brass alloys, cast iron, and other materials with anti-corrosion coating.

Photo 1. Metal three-way valve for the heating system, with an adjustment washer on top.

The regulating element is rod or ball, located inside the three-way valve. When the temperature exceeds the set values, this element reduces the flow of liquid from one of the channels. It works using an external (hydraulic, electric, pneumatic) drive.

Reference! Ball valves have a higher flow capacity because their control elements create more low hydraulic resistance.

How does it work?

Through one input of the valve is supplied heated coolant, through another - return (cooled stream).

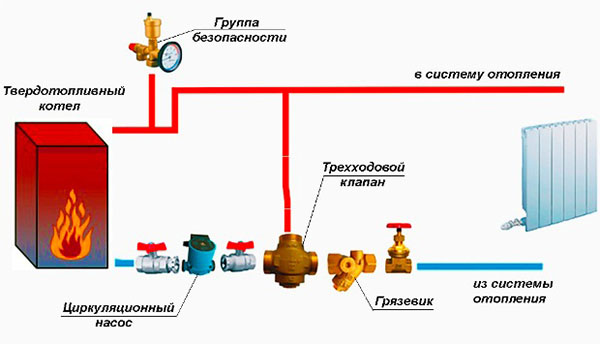

Photo 2. A diagram showing the operating principle of a three-way valve in a heating system with a solid fuel boiler.

The water mixed to the optimum temperature comes out of the outlet pipe. Inside, under the adjustment element, there is a temperature sensitive sensor — a container filled with a liquid or gaseous substance.

When heated, the contents of the container expand, acting on the actuator, which causes the mechanism to operate.

Where do they put it?

The choice of the three-way valve insertion scheme is selected taking into account the nature of the heating systemMixing and separating valves are cut into the supply pipe from the heat source, the collector at the junction with the bypass.

With this connection, the superheated coolant will be able to circulate in a small circle (separation) or will mix with cooled water.

To divide the circuit flows, the device is sometimes placed on the return pipe at the junction with the bypass jumper. In all cases, the valve is mounted paired with a circulation pump.

Bypass - backup path for coolant, ensuring the operation of the system in emergency situations. It is made in the form of a jumper between the supply and return pipes.

Varieties by the principle of operation in the system

- Mixing. They lower the temperature of the coolant by mixing hot water and a cooled stream. Equipped with one inlet and two outlets. They are used to regulate the flow temperature.

- Separating. Without changing the temperature, will divide the flow into two. One inlet pipe, two outlet pipes. They are used to redirect the flow to different circuits.

Photo 3. Three-way separating valve, has two outlet pipes and one inlet.

Classification by management method

The drive is a control element that causes the control rod (ball) to move and ensures functioning of the entire device.

Drive units can be either electromechanical, pneumatic, hydraulic, and manual. According to the control principle, three-way valve drives are divided into the following types:

- Thermostatic. The internal cavity contains a heat-sensitive element enclosed in a special container. When heated, it increases in volume, affects the rod, and makes the entire mechanism work. The drive is easily removed and is used for small-diameter products used in domestic heating.

- Thermostatic head. Equipped with a temperature-sensitive sensor, located in a pipe and connected to the drive by a special capillary tube. Performs more precise adjustment than a thermostat.

- Electric drive with controller. Sensitive sensors measure the temperature of the coolant, transmit information to the controller, which gives a signal and makes the mechanism work. Such a drive device performs very precise adjustment.

Photo 4. Three-way valve with thermostatic mixing actuator makes the entire mechanism of the heating system work.

- Servo. A simplified version of the previous type. There is no controller in the valve, the actuator receives signals from the sensor and controls the rod directly.

Important! The simplest drive in terms of design is manual. Adjustment is made by turning the cap connected to the top of the rod.

Four criteria for choosing a thermostatic mixing device

- Number of contours. For single-circuit heating, heating of small rooms, valves with a thermal head are suitable. For complex branched systems with many circuits, it is necessary to install a mixing unit, in which valves with an automatic electric drive are used.

- Diameter. The smaller the cross-section of the inlet pipe, the greater the hydraulic resistance, at which the device does not work correctly. Therefore, the diameter should not be less than the cross-section of the heating equipment circuits.

- Bandwidth. For the optimal choice, compare the value of the valve capacity coefficient specified in the instructions with the overall performance of the heating structure.

- Material. Brass has high corrosion resistance and strength. In addition, taps with bodies made of copper-based alloys are noticeably more durable and lighter than cast iron ones.

What does the cost depend on?

The most expensive models are - equipped with high-precision sensors and programmable thermal modes.

According to the set values, automatic regulators change the temperature of the circulating water depending on the time of day.

And also the price depends on the manufacturer, The most expensive shut-off valves are produced by Western companies, the most affordable ones are produced by joint ventures with factories in Russia (Valtec).

Attention! It is not recommended to save on the functionality of the equipment, since a correctly selected three-way automatic valve will help reduce fuel consumption by up to 50%.

Installation and connection: how to install it?

Devices with any type of drive are installed in the same way. The main difficulty does not consist of connecting the tap to the system, but in drawing up the correct heating scheme, determining the valve location in it and selecting equipment. For accurate calculation of the system you need to have special knowledge, so it is better to entrust the installation to qualified specialists.

Installation instructions

Thermostatic elements usually have factory fixed setting. Servomotors are configured using controllers, following the instructions provided.

- Prepare a three-way valve, tools for installation.

- If the heating circuits were previously used - drain the water.

- Position the valve downstream of the flow, according to the arrows on the case.

- Check the holes of the product, residual welding particles, debris, and dust should not get into them.

- Position the axis of the thermostatic head perpendicular to the axis of the pipeline. Any mounting position is acceptable, except when the actuator is located below the valve.

- Make the assembly easily removable for possible replacement. To do this, mount the valve using special connectors with internal or external threads and seals or "American" fittings.

General recommendations

- Three-way valve is cut into the circuit before the heating pump.

- Before the device A coarse filter is installed.

- Pressure gauges are a must are mounted before and after the valve.

- Tensile loads are not allowed to act on the body., torsion, compression, bending from the water supply.

- For correct operation with unstable pressure before the valve Throttling devices are installed.

- When installing the drive should always be located above the tap.

- Please follow the manufacturer's recommendations as specified in the technical data sheet.

Which manufacturers can be trusted?

The market offers a large selection of shut-off and control valves reputable brands and unknown companies.

Valves lead the popularity ratings Swedish brand Esbe, distinguished by reliability and durability. No less high-quality products are produced by Korean concern Navien.

Three-way fully automatic valves with high adjustment accuracy are manufactured by Danfoss (Denmark). Products American brand Honeywell are distinguished by their simple design and ease of installation. The combination of affordable price and quality is a distinctive feature of the valves Valtec company.

Useful video

In the video, a specialist talks about the features of installing a three-way valve in a heating system.

Conclusion

Correct selection and connection of the three-way valve will ensure correct operation of heating with any number of contours. When purchasing, give preference to models that come with a guarantee and technical documentation.