Provides access to fresh air and high-quality operation of the device - ventilation for a gas boiler in a private house

In a gas boiler room, oxygen is needed to improve the combustion process. To ensure that air constantly enters the room, it must be regularly ventilated.

And also with the help of ventilation the room is cleared of harmful products, which are formed as a result of the combustion of natural fuels.

In addition, the gas itself also causes poisoning, so for safety reasons the boiler room should be well ventilated. As a result, ventilation for a gas boiler in a private house can solve several problems at once.

Features of the ventilation design

There are different types of ventilation structures, each with its own characteristics. In modern gas boiler houses the following options are used:

- Mechanical And natural.

- Supply, exhaust And mixed.

- Ductless And channel.

Selection of the draft principle, ventilation purpose and its design solution depends on the tasks that are set for the system. As a rule, this is written in the instructions for the gas boiler.

For example, for a device with an open combustion chamber that has high power, natural draft may not be enough, so a mechanical injection system. It provides an air flow, which guarantees a sufficient amount of oxygen for combustion. It happens that the air itself does not come out well from the boiler room, so an exhaust ventilation is also installed.

The boiler room may have several small rooms or sections. Provided that the air movement in the boiler room is intensive, they equip ductless system. For this purpose, holes are made in the walls of the sections. But even passing through them, the air is removed through a channel system, which is an air duct that goes outside.

Reference. Ensure the supply and exhaust of air 100% allows mixed variant, when ventilation works on artificial air inflow and removal. It is capable of completely isolating the room from combustion products. channel system, taking them out through a separate pipe.

Requirements for ventilation of a gas boiler in a private house

For efficient and safe operation of a gas boiler, it is necessary to comply with the requirements for its installation.

First of all, for high-power devices it is mandatory a separate room - a boiler room.

It is necessary to highlight it precisely because of the inability of ventilation to remove exhaust air from living spaces, as well as due to the explosive nature of the fuelThis primarily applies to large private houses that are heated by floor-standing boilers equipped with an open combustion chamber.

Attention! Using the basement as a boiler room if the boiler is working on liquefied gas — unacceptable. The boiler room is located in a separate building, since liquefied gas has a high specific gravity and in case of a leak it accumulates and creates a risk of explosion.

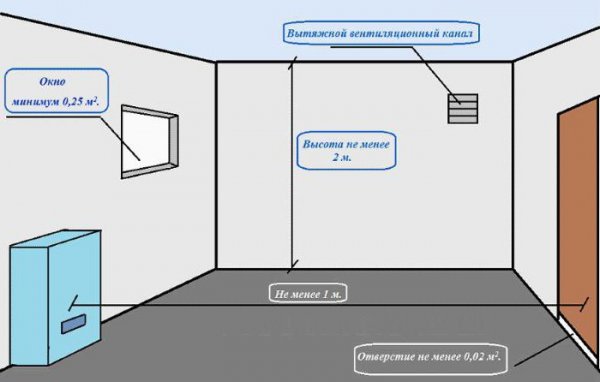

According to SNiP 2.04.05. II-35, such rooms must be equipped with a ventilation system. Opening windows and a separate, permanently open air vent facilitate the operation of the ventilation system — also specified in the list of requirements. The ventilation duct must be located at the top of the room. It is equipped with an inspection hole for cleaning, since contamination of the air duct can interfere with air exchange. In this case, it is better if the air duct of the channel ventilation is made of non-combustible material.

Photo 1. Scheme of the boiler room in a private house. The arrow indicates the location of the ventilation duct.

For small rooms where low-power wall-mounted gas boilers are installed, ventilation can be equipped in utility rooms (bathroom, kitchen). In such devices, a closed combustion chamber operates, and the inflow and removal of air is carried out via a coaxial (pipe in pipe) air duct, which is separately led out to the street through the wall.

Construction of ventilation for a gas boiler

The construction of a ventilation structure consists of several stages.

Selecting a project

The ventilation design for a private house is worth choosing at the stage of preparation of construction works. This will allow taking into account all the parameters necessary for the efficient operation of the system. This is especially relevant for large houses where separate boiler rooms are equipped with gas boilers (usually floor-standing) with an open combustion chamber.

For such places, as a rule, they choose mechanical supply and exhaust duct ventilation. The diameter of the air duct, the operation of the ventilation mechanisms and the layout are calculated based on the technical characteristics of the boiler and the required power. They, in turn, depend on the area of the heated territory and air exchange.

Photo 2. Diagram of the mechanical supply and exhaust duct ventilation system in a private one-story house.

A wall-mounted boiler with a closed combustion chamber and a coaxial air duct is installed in a small house or even an apartment. There is enough space for its installation in the kitchen, toilet or bathroom, where the boiler is mounted on the wall. A coaxial air duct is installed on it (if it is an external wall), which performs both the functions of ventilation and a chimney: One pipe works to supply air, and the other to remove combustion products.

But even with such a seemingly safe device, it is necessary additional ventilation of the room. It is best if it is of a mixed type. At the very least, it would not be superfluous to equip an additional ventilation supply valve in the wall.

Materials and tools

Once the ventilation system calculations have been made and the project is ready for implementation, it is necessary to prepare the materials for ventilation installation and the appropriate tool. To choose the right materials, you need to know where and how the ventilation duct will go and what load is it designed for.

For example, duct ventilation can be made from galvanized boxes, which can withstand heating well.

In this case, the channel is assembled from sections that are sealed using a flangeless (sealing tape) or flanged (gasket) method.

After assembling the channel, use the following to mount it on the wall or ceiling: clamps. A mechanism for forced ventilation is mounted in the channel itself. On the ventilation opening facing the street the grille is being installed to protect against insects and debris.

The other end of the duct ventilation is hermetically connected to the gas boiler. Only the coaxial air duct, which is sold ready-made, is brought out and connected to the boiler, does not require special assembly.

Set of tools for installation:

- calipers;

- drill or hammer drill;

- screwdriver and impact wrench;

- hammer and chisel;

- roofing shears;

- adjustable wrench.

Some tools perform several functions at once.

For example, a drill can be used to make holes for mounting a ventilation box, and larger cutouts can be drilled in the walls around the circumference to install large-diameter communications.

A hammer and chisel are used to clear the area where the air duct will be installed.

Calipers allows you to measure the diameter of the device and check its compliance with the calculations. Roofing shears useful for cutting and trimming metal sheets from which a box or pipe is made. Impact wrenches, as well as adjustable wrenches are needed to secure the ventilation structure.

Construction stages

The main phases of ventilation construction:

- Preparation;

- installation;

- testing.

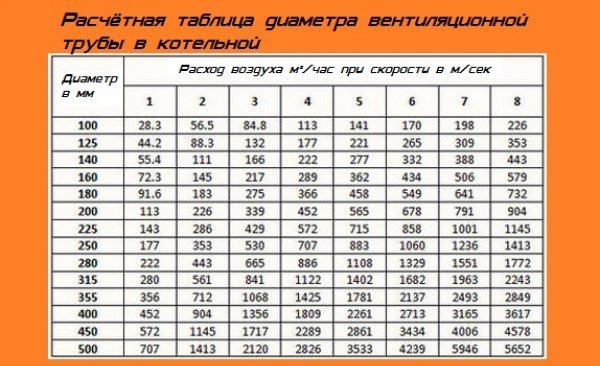

At the preparation stage, the following calculations are carried out: the volume of the room is multiplied by the air exchange, which provides information about the air circulation in the room. Then, using a special table based on this data, the diameter of the pipes is determined. For example, when the air flow rate 113 cubic meters per hour the required diameter of the air duct will be 200 mm.

Photo 3. Table for calculating the diameter of the ventilation pipe in the boiler room depending on the air flow.

Considering that a good microclimate in the boiler room requires a threefold air renewal within an hour, the ventilation design includes a supply and exhaust or mixed mechanism. When everything is ready for the ventilation installation, start installation:

- In the wall, a circle marks the area for the hole through which the air duct will pass. Moreover, the dimensions of the circle exceed the diameter of the pipe.

- Drill (perforator) in a circle Several holes are made.

- With a hammer and chiselthe cut out fragment is knocked out, and an air duct is inserted into the hole.

- Remaining gaps are closed with polyurethane foam or mortar.

- An exhaust fan is installed (the supply air can be installed in a similar way, but at the bottom of the wall and at the other end of the room).

- Above the passage is closed by a grateso that it is not contaminated by foreign objects.

For small boiler rooms with an area of up to 6 sq. m, natural ventilation may be sufficient.

The situation is even simpler with a coaxial air duct, where all the required elements are already available, and the device only needs to be mounted into the wall.

When everything is ready, the ventilation is tested. To check the operation, you can use both the "folk" method and special measuring instruments:

- In the first case a match is brought to the opening of the channel and if the flame leans towards the hole, then the system is working normally.

- If it is necessary to accurately check the compliance of the air flow in the room with the calculated values, then the following is used: anemometer.

Useful video

Watch the video, which talks about the features of the ventilation device for a wall-mounted gas boiler.

How to control the operation of the structure

The main task of the ventilation system is to provide sufficient oxygen supply.

On the one hand, he maintains the microclimate in a normal state, on the other hand - ensures complete combustion of fuel And heat release.

If the flame becomes yellow, high and creates a lot of soot, then the supply of oxygen that promotes combustion is limited, and the operation of the ventilation system in the boiler room must be adjusted.

A person's well-being is also an indicator! If a person in the room feels lethargic, tired, and has difficulty breathing, then something is wrong with the ventilation. It is necessary to clean it, replace the elements yourself, or call a technician.