Without it, the operation of the heating device is dangerous! Types of pressure gauges for adjusting gas boilers

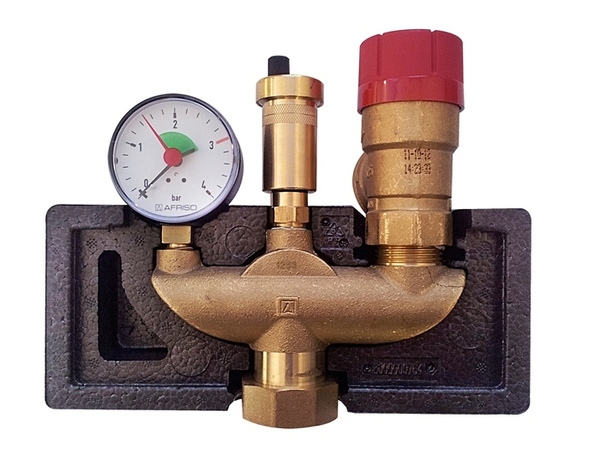

The pressure gauge exists for this purpose. to measure the pressure in the system. It is connected to the emergency relief valve and air vent, thus, guaranteeing safety.

Pressure readings outside the permissible limits mean that the system is not working properly. Excessive pressure can lead to a pipeline rupture and even an equipment explosion.

Content

Classification of pressure gauges for adjusting gas boilers

The operating principle of all pressure gauges is based on the fact that the measured pressure is balanced by the force of the tubular spring or two-plate membrane.

One end of it is soldered to the holder, and the other is connected to the arrow through a special mechanism. This mechanism converts the linear movement of the sensitive element in the movement of the hands on the dial.

Exemplary

Measuring instruments that are called standard instruments are those that used to calibrate others. This type of device is used to test equipment and accurately measure liquid and gas pressure, they have a higher accuracy class - 0.015—0.6 units The increased measurement accuracy of these devices is due to the design features: the gear element in the transmission mechanism is made very precisely.

Electrical contacts

These devices monitor the maximum pressure and notify the system when it is reached. Usually this type of measuring equipment is used for gas, steam, calm liquids that are not prone to crystallization. The devices can control external electric circuits when critical pressure is reached using a contact group or an optical pair.

Photo 1. Electric contact pressure gauge for a gas heating boiler. The device has a dial with divisions.

Special

They are applied for measuring excess pressure in a gaseous medium. Each type of such device is intended for a specific gas, the name of which is indicated on the scale. Special pressure gauges are also marked different colors and letters in the name. For example, a device designed to measure ammonia pressure has a yellow case and the letter "A" in its name. This type is additionally protected from corrosion. Accuracy class of special devices 1.0-2.5 units

Ship

The peculiarity of the devices is increased protection from moisture, dust, vibrations. These pressure gauges are mainly used in shipbuilding, hence their name. They are suitable for measuring the pressure of liquid, gas, and steam.

How to choose a pressure gauge for adjusting a gas boiler

When choosing devices, it is necessary to consider: type, measurement range, accuracy class, size, functional load, operating conditions.

Types of devices

According to the structure and principle of operation, there are 5 main types sensors:

- liquid;

- spring;

- electrical contact;

- membrane;

- differential.

Spring and liquid devices are the most popular. They are quite accurate and reliable at a low price. These two types are well suited for private homes and small businesses. Most boiler houses use spring pressure gauges.

Gas pressure measurement range

This is the most important parameter when choosing measuring equipment for a boiler room.

The main thing is that the working pressure in the boiler pipe falls in the range of 1/3—2/3 of the scale measurements of the device. If the pressure is less, then the measurement error is too high, and if it is more, the device will be overloaded and will fail before the warranty period.

Accuracy class

The less this indicator, the more accurate device. Accuracy class — this is the percentage of error measurements from the measurement scale.

The error is easy to calculate, for example, if the device is on 10 atm. has a precision class 1.5 units, then its permissible error is 1.5%If the device reading is higher, it must be replaced.

The fault can be identified only with the help of a reference pressure gauge, this is done by a special organization that verifies the equipment. A high-precision device is connected to the system, and then the readings are compared.

Size

Diameter devices are selected depending on the purpose.

- 50, 63 mm — for installation on portable equipment or for monitoring the pressure of oxygen cylinders, welding machines.

- 100 mm — the most common size, the most convenient in most cases.

- 160 mm, 250 mm — to control devices that are located visually far away, for example, under the ceiling of a boiler room.

Functional load

According to the type of functional load, devices are classified as:

- Showing — these are technical devices. They measure pressure.

- Signaling — control the external electrical circuit.

- For accurate measurement have accuracy class 0.6-1.0 units

- Exemplary are used to check the accuracy of other instruments.

- Self-recording record the pressure in the form of a diagram on paper.

Photo 2. Model pressure gauge for a gas boiler. The device has high accuracy and is used to calibrate other devices.

Operating conditions

The device is being selected taking into account the environment in which it will be used. The environment can be different, including aggressive. There are devices with different cases, it is important to consider whether it will work in conditions of humidity, dust, vibration, in order to exclude the development of corrosion or damage to the case.

Installation rules for the device

The pressure gauge must not be installed if:

- There is no seal or mark indicating that the inspection was carried out.

- The verification period has expired.

- There is visible damage, such as cracks.

- The arrow does not return to zero when turned off.

- Installation at a height of more than 3 m from the site is prohibited.

The device is installed in such a way that the readings are clearly visible. The scale should be vertical or have tilt 30°.

The diameter of the pressure gauge should be not less than 100 mm, at a height 2-3 m — not less than 160 mm.

The device must be sufficiently illuminated, but protect from direct sunlight And environmental impacts.

The pressure gauge must be tightened onto the tee, but the device itself must not be tightened enough to allow all the air to escape unhindered.

Attention! If a breakdown of the device is detected, then it must be submitted to a service center, having previously cleaned it.

Tools and materials

For installation you need a minimum set of tools that are available in every home. You will need: a plumbing kit, a nipple and a wrench, the pressure gauge itself, a three-way valve and an impulse tube in cases where such a method of fastening was chosen, where it will be required. In some cases, an adapter is needed.

Direct installation

The pressure gauge is screwed on immediately on a pre-welded adapter with special sealsThis method is the simplest, it is used where there are no constant pressure surges and frequent replacement is not required.

On a three-way valve

On a pre-welded adapter A three-way valve is installed, and a pressure gauge is installed on it.

Photo 3. Manometer for a gas boiler, installed on a three-way valve. With this installation, the device is easier to operate and is easy to replace.

This method is used if during testing it is necessary to transfer the equipment to atmospheric pressure using this valve. With this method of installation, the pressure gauge can be replaced without interrupting the system operation.

Using a pulse tube

The device is also installed through a pulse tube, which will protect it from damage. For this purpose, a pre-welded adapter attach a tube and a three-way valve to it, and a pressure gauge is screwed to it.

Thus, the installation is carried out where contact of the measuring device with hot steam is possible. This method protects the pressure gauge from damage.

Examination

Checking measuring equipment with a three-way valve is carried out as follows:

- In working position notice the indications devices.

- Three way valve slowly turn left a quarter turn. The pressure gauge is disconnected from the boiler and connected to the atmosphere, the arrow should smoothly return to zero mark.

- Turn the tap slowly back to the right a quarter turn, the instrument arrow should return to the previous position.

If the arrow moves in jerks, it means that the nipple and tap are clogged, they need to be blown outTo do this, turn the tap so that water (gas) flows, then return it to the working position.

Important! The accuracy of the pressure gauge is checked only using a reference instrument.

Useful video

Watch the video, which talks about the features of the pressure sensor in a gas boiler.

Conclusion

Pressure gauge readings It is important to check regularlyAn increase in pressure may indicate an air lock, a clogged pipeline, or incorrect installation of the boiler.

A drop in pressure indicates a possible leak in the pipeline circuit.

By regularly checking the pressure gauge, you can set up the boiler optimally, avoid system breakdowns and even emergency situations.

If installation or replacement of the device is necessary, then you should contact specialists. Installation and testing must be carried out by a qualified technician using special equipment.