Correct connection is the key to safety! Installation of a gas boiler for heating

Installation of gas boilers to provide autonomous heating and water heating is used in private residential buildings and apartments.

The installation process includes preparatory work, hanging the boiler, connecting it to utilities and a test run of the system.

Content

Materials and tools

To perform preparatory and installation work yourself, you will need the following tools and materials:

- building level to check the verticality of the walls and the suspension of the unit;

- drill or hammer drill with a set of drills for making wall holes;

- fireproof sheet for fixing between the wall and the gas boiler;

- plastic pipe for the production of room ventilation;

- metal pin, several corners for the design of the grounding circuit;

- electric welding machine with electrodes for welding metal parts;

- screwdriver, hammer, screws and nails for fastening the supporting supports of the device;

- three-wire cable length from 3 m and section 5-7 mm for grounding;

- sealant for connecting the heating system and gas pipeline.

Preparing a place for installing a gas boiler in a private house

The room for installing this device should not be smaller than 4 m2and with ceiling heights less than 2.5 mIt should have a door and window opening with a transom.

Important! Installation of gas equipment is not permitted. balconies, in toilets and bathrooms.

Wall with space for the device must be strictly vertical, deviations are checked with a building level. If the wall is sloping, its surface must be leveled with plaster.

Depending on the material of the walls underneath the device itself, it may be necessary additional thermal insulation.

A fireproof sheet is attached to the wall at the future location of the boiler. made of asbestos or steel using a screwdriver.

If the walls are brick with a plaster coating, additional thermal insulation is not needed.

In closed spaces where there is no free air circulation, installation is necessary. exhaust pipe to prevent the concentration of carbon monoxide in the event of an emergency leak. If the gas boiler is planned to be installed in the kitchen, a good solution would be to combine the kitchen hood above the gas stove and the ventilation pipe. To the hole in the ceiling through a flexible corrugated tube with a diameter of not less than 10 cm attach the exhaust pipe protruding 50 cm higher the ridge of the roof of the house.

The boiler requires installation of a grounding circuit and a voltage stabilizer for the electrical network. If you have to buy a stabilizer, then you can do the grounding yourself. The grounding design includes:

- a metal triangular frame dug into the ground to a depth of 50 cm;

- a pin or a metal rod 10 mm thick, welded to the frame;

- conductor from the boiler to the stud (three-wire cable);

- plastic fence around the junction of the conductor and the stud.

Reference. The ground wire is connected to the boiler during its installation.

Preparatory work may be performed in any order.

DIY chimney installation

To supply oxygen to the chamber and remove combustion products of gas, any boiler installation must be equipped with coaxial chimney. There is no need to purchase it separately; it is included in the gas boiler delivery set along with installation instructions.

Photo 1. Details of a coaxial chimney, which is usually installed together with gas boilers.

A coaxial chimney is a plastic pipe, consisting of two parts — external and internal circuit. Combustion products are emitted into the atmosphere through the internal pipe. Air is supplied to the combustion chamber through the external circuit using a fan. The flue is connected to the boiler on one side, and the other side of the chimney is led outside the wall. To do this, a hole of a suitable diameter must be made in the wall above the boiler location using a hammer drill.

How to install a heating system correctly

Connecting gas equipment to the heating system is connection of the pipes of the installed device with the water supply for supplying cold water. Hot water circulates through the pipes from the boiler throughout the entire heating circuit.

To ensure a water-tight connection, it is essential to use construction sealants (flax, sealing tape). Pipe joints must be made using a water filter and taps.

Important! The presence of rotary valves on water pipes will allow local turn off the water supply to the boiler if necessary.

Connecting to a gas source

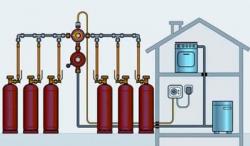

Connecting a local gas pipeline to the main gas pipeline is carried out through a gearbox, equipped with a filter and a gas pressure regulator. The pipe through which the gas enters the boiler is equipped with a shut-off valve or tap.

The connection between the gas pipeline and the boiler branch pipe is performed using a corrugated flexible hose made of steel.

Photo 2. The place where the boiler is connected to the gas source. A special steel hose is used for this.

All connections needs to be compacted to prevent gas leakage. Plumbing tape cannot be used for this purpose, it does not guarantee sufficient sealing of volatile substances. For gas connections, a suitable sealant is tow and paint.

Attention! For gas pipe connections Rubber hoses are not used!

Test run of a gas boiler

First start-up of gas equipment performed by service center specialistswhere it was purchased, or the local gas service staff.

To perform the first start-up, it is necessary to fill the heating system with water, supply gas and connect the boiler to the power source.

Step by step the process looks like this not difficult. At first filling the system with water. Filling of connecting pipes and radiators is carried out gradually, controlling the release of accumulated air to avoid the formation of air locks. Excess air is released by successively opening the taps installed on each radiator until water begins to flow from them. The remaining air is expelled by adjusting the boiler pump valve.

Rechecking the tightness of all connections. The reliability of the gas supply pipe connection to the boiler is checked with a special device, as well as with a soap solution and a brush. The solution is applied to the joints; if no bubbles appear on them, the connection is safe.

Connecting the boiler to the gas pipeline: open the gas supply valve.

Connecting the device to the electrical network through a voltage stabilizer.

After a successful launch, you will be issued certificate for warranty, post-warranty repair And technical maintenance.

Commissioning of gas heating equipment is not possible without drawing up design documentation and concluding a gas supply agreement with the local gas authority. For each type of operation of preparation, installation of gas equipment, it is necessary to obtain permission and draw up documents on the suitability of use of the finished system.

Attention! It is strictly forbidden to carry out the first launch of the system independently! The strictness of control is related to increased risks of use in domestic conditions explosive devices.

What to do if you detect signs of incorrect boiler connection

If any faults are detected in the installed device or even suspected of them, you should disconnect the appliance from the power supply, immediately turn off the gas valve And Contact the service center. If you suspect a gas leak (there is a characteristic smell in the room), you must immediately call the emergency service.

Important! If the gas boiler is under warranty, attempts to fix the problem yourself, will result in failure of the unit to be serviced.

Useful video

Watch the video, which explains how to properly connect a wall-mounted gas boiler.

Possible risks

Connection or installation errors of a gas boiler with violation of technical standards threaten with serious consequences:

- Absence fireproof lining between the wall and the boiler causes a fire.

- Absence grounding leads to the formation of static electricity on the surface of the boiler, failure of sensors, and the occurrence of an electric arc.

- Availability air locks The system is dangerous due to rupture of heating pipes and failure of the boiler pump.

- Absence additional ventilation And leaky connection gas pipeline leads to the accumulation of carbon monoxide in the room and poisoning of residents, even death.

This is far from a complete list of possible problems. Installation of gas boiler equipment according to rules and instructions guarantees its safety of use, serviceability and durability.

Comments