The ideal option for heating a house: a single-circuit gas boiler, which one to choose?

Gas heating is an effective way of heating private homes, first of all due to the low cost of main gas, and also high efficiency rates, inherent in such forms of heating.

At the same time, the boiler is the central element of any local gas heating system, directly responsible for the generation of thermal energy and its transfer to the circulating coolant.

The structure and operating principle of a single-circuit gas boiler

Modern boilers are classified according to technical specifications, and also by design features, first of all - by the number of connected circuits. Single-circuit boilers are used only for heating, double-circuit analogues, in addition to heating, allow providing heated rooms with autonomous hot water supply.

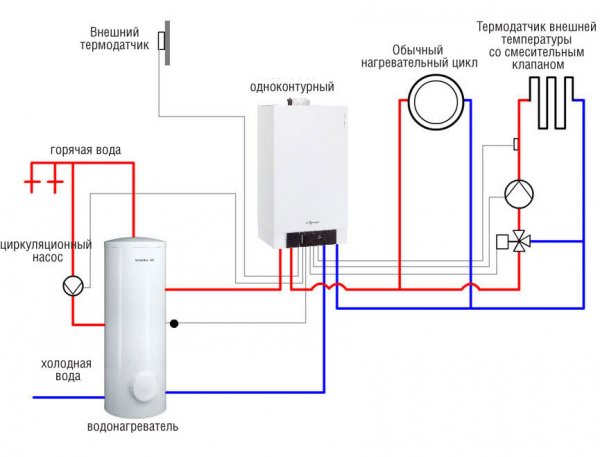

Photo 1. Diagram of installation of a gas boiler together with a water heater. The first device provides heating of the heating system, the second water supply.

The design of any single-circuit boiler includes the following elements:

- direct and return supply pipes;

- a combustion chamber equipped with a burner;

- heat exchanger;

- chimney;

- control system and electronic elements responsible for automation.

In addition to the above components, some single-circuit models are equipped with built-in expansion tanks, leveling the thermal increase of the coolant, and circulation pumps, accelerating the pumping through the heating circuit. However, the need for these elements is determined based on the characteristics of the boiler used and the design features of the entire system.

Important! An average single-circuit gas appliance is capable of providing effective heating of rooms with a total area up to 300 m2.

Regardless of the configuration, The operation of each single-circuit gas boiler occurs according to the following scheme:

- An air-gas mixture is fed into the combustion chamber through injectors. When it is burned, thermal energy is generated, which is directed through a heat exchanger to heat the coolant (water or a special antifreeze), continuously circulating in the heating circuit.

- The coolant transfers heat from the boiler to the radiators, installed in heated rooms, after which, in a cooled state, it returns to the boiler and the cycle repeats from the beginning.

Thus, the main difference between the design of single-circuit boilers and double-circuit analogs is the ability to connect only one liquid circuit, responsible for heating. Other features of the devices under consideration depend on the specific modification of the unit.

Main types

Boilers are classified depending on the following design features:

- Installation method. Available for sale wall and floor units: the first are installed on the floor or on a special base, wall-mounted ones are attached to the wall. Floor-mounted designs are characterized by high power, durability and autonomy, wall-mounted ones are compact.

- Combustion chamber type. In models with a camera open type, air supply and combustion product removal occur naturally: air comes from the room in which the boiler is installed, and exhaust gases are discharged into a traditional vertical chimney. In boilers with a chamber closed type of air supply and removal is carried out forcibly, due to the operation of a built-in turbine: circulation is carried out automatically through a coaxial chimney, which is discharged to the street through the wall.

- The principle of using thermal energy. In single-circuit convection boilers use only the heat generated by burning the air-gas mixture to heat the coolant - while some of the thermal energy is lost, since it is contained in the combustion products that are removed. Single-circuit condensation The boilers are equipped with an additional heat exchanger, which is responsible for extracting the thermal energy contained in the exhaust gases.

- Heat exchanger material — are made from cast iron or steel. The former are characterized by high corrosion resistance, increased thermal conductivity and a long service life. Steel heat exchangers are less durable, but more resistant to temperature changes and mechanical impacts.

Photo 2. Single-circuit gas boiler made of cast iron. The control panel is located in the upper part of the device.

- Method of ignition. In devices with piezo element to start the unit, you need to manually press the corresponding button. In models equipped with the system automatic Ignition, connection and shutdown of the boiler are carried out in autonomous mode, in accordance with the settings specified by the user.

- Burner typeThe ability to regulate the intensity of the gas burner installed in the combustion chamber depends on this design feature of the unit. Ordinary burners do not allow you to change the saturation of the flame, while modulated elements provide such an opportunity, both in manual and automatic modes.

Reference. The choice in favor of one or another modification is made depending on operating conditions, and also personal preferences And financial capabilities of the user.

Advantages

In addition to the general advantages of heating equipment operating on main gas, Single-circuit boilers are also characterized by:

- Easy to installProvided that you have the necessary knowledge and practical skills, installing a floor or wall-mounted unit yourself will not cause any difficulties.

- Reliability. The design of single-circuit gas boilers is simpler compared to double-circuit analogs, which implies greater reliability during operation, as well as comparative cheapness and ease of repair in case of breakdown.

- Convenience and safety. Most modern single-circuit boilers are automated to one degree or another, which significantly increases the convenience and safety of operating the units.

- Wide range of functions and settings. A high degree of automation allows the use of single-circuit gas boilers in various modes.

- Availability — the devices are significantly cheaper than their dual-circuit counterparts.

Flaws

Regardless of modification and technical parameters All single-circuit gas boilers have the following disadvantages:

- Limited scope of application - By default, they are designed only for heating, which significantly reduces the operating capabilities of the devices.

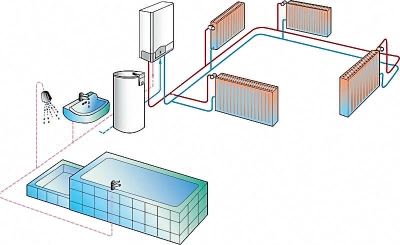

- Need for additional equipmentTo organize autonomous operation of hot water supply or installation of "warm floor" it will be necessary to purchase and integrate additional devices into the heating structure, in particular, boilers indirect heating.

Attention! The cost of purchasing additional elements will also be added cost of calculation and installation works. Independent installation of devices that expand the functionality of a single-circuit boiler is permitted only subject to the availability of relevant knowledge and skills.

Useful video

Watch the video, which compares single-circuit and double-circuit gas boilers, and tells you which one is better to choose.

Reasonableness of purchase and use

The range of effective application of single-circuit gas boilers is limited by their main property - the ability to connect a single circuit responsible for heating. Thus, the purchase and operation of such units are justified in cases where the heated premises are already connected to the centralized hot water supply circuit or when hot sanitary water is not required at all.

Comments