30 years of reliable service is quite real. Types of fasteners for cast iron heating radiators

Modern fastenings are characterized by increased durability, ergonomics, reliability and practicality.

Certified materials used in the production of products, comply with international standards and have a dense structure capable of withstanding the weight of equipment and coolant.

Content

Functions and types of fastenings for radiators

Fastening systems designed for rigid fixation radiators, thereby preventing damage to heating mains.

Reliable fastening maintains functionality heating circuits and fittings during the entire period of operation.

Batteries that are mounted in a vertical position will have maximum efficiency and will create a dense thermal curtain separating the room from the cold air flows from the window.

Cast iron utensils have a large mass and put stress on 10-20 kilograms per fastener and point on the wall, so it is important to select products taking into account the intended method of installing radiators. Combined fastening systems will be an excellent option for private homes and apartment buildings.

Cast iron brackets

Solid cast iron fasteners are distinguished by their strength and durability and ability withstand a very large massBrackets made of this material are in demand when installing cast iron equipment and heavy building heating systems.

Important! In addition to the fact that cast iron pins must be of high quality, it is necessary install them correctly on the wall to ensure reliable operation of the heating circuits.

Steel fasteners on strip and with pin reinforcement

Fasteners on the strip made of steel are quite easy to install and provide reliable support for radiators throughout the entire operating period.

The strip can be attached on concrete and wooden walls. For installation of batteries consisting of less than 10 sections, will be enough only two fastening strips made of steel.

Steel fasteners with pin reinforcement are mounted into the wall using special dowels, providing increased wear resistance and resistance to shape change and sagging. Durable steel parts are perfect for mounting both lightweight batteries and cast iron radiators.

Adjustable steel mounts

These fastening systems very easy to use and allow you to change the position of the radiator without removing it.

Important! When purchasing steel adjustable mounts, you should take into account the thickness of the metal and the expected load on them.

How to fix cast iron radiators

Depending on individual characteristics premises, you should select an installation option for the products that will ensure an even distribution of the load and prevent the destruction of the wall of the home.

To the wall

Installation of wall mounting systems is the most popular way, used when installing heating in a house.

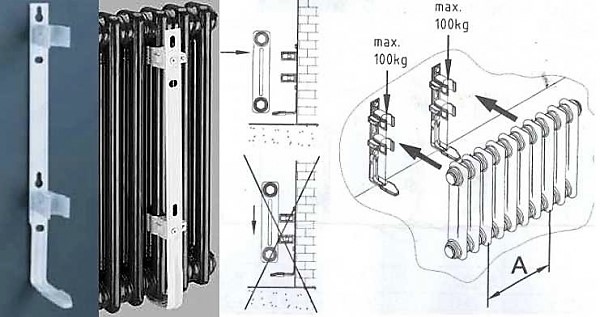

Photo 1. Quick wall mounting of radiators using a special bar with clamps. Maximum load 100 kg.

Fastenings designed for increased loads from the equipment side and can ensure long-term service even in adverse operating conditions. Most systems are used for installation on brick, concrete and wooden walls. Wall mount for cast iron radiators won't fit for home improvement made of plasterboard and lightweight foam blocks.

Floor standing installation

In cases where the walls are not designed for installation of cast iron radiators, floor fasteners will be an excellent solution. Fasteners carry the entire mass radiators on the floor and relieve the load from the walls. Despite the fact that the floor fasteners quite reliable and stable, sometimes installation is required additional wall fixings, holding the batteries in a certain position.

General recommendations

Recommendations for installation of heating devices:

- Cast iron radiators need to be positioned at a distance of 3-5 cm from the wall, 6-12 cm from the floor And from the window sill 5-10 cmThis position will ensure the best heat transfer.

- The center of the radiator should coincide with the center of the window opening to create warm currents that prevent cold air from entering the home.

- Before installing the fasteners, you should mark the points, into which they will be mounted.

- Fasteners are important securely fix. For this purpose, the following can be used: dowels, plugs and cement mortar.

- Once the fasteners are installed, the batteries are mounted according to the planned scheme.

- Radiators must be assembled correctly and the nipples are tightened. It is also important to put on all free collectors plugs.

- They are mounted on batteries manual or automatic air vents, helping to improve the efficiency of the system.

- Shut-off valves, which is installed on the inlet and outlet openings, will make the process of heating the house more comfortable. Ball valves allow you to remove the radiator without stopping the entire heating system.

- When connecting the circuit, it is important select the correct size of fittings, compatible with pipe diameter heating.

- The final stage of installation is pressure testing equipment.

Useful video

Check out the video that tells and shows how to install a cast iron radiator on a wall.

The correct selection of fastening systems is the key to reliable heating

Installation of heating systems is usually carried out once every 20-30 years. Such a long service life requires the use of high-quality materials and reliable fastening elements of the system. Fasteners of different types will perfectly cope with the task and add individuality to the interior.

Comments

To attach the hooks, I first marked their location and drilled a hole in the wall, inserted a dowel, then screwed the hook into it, the main thing is to screw them to the same depth and calculate so that the suspended battery leaves a gap from the wall, in my case this gap is about 4 cm.