Correct calculation will save you from heat or cold! Calculation of heat output of cast iron heating radiators according to the table

Heating systems are created to maintain comfortable conditions for living or performing various types of work. During the heating season, heat loss is compensated for using heating devices..

They are cast iron, aluminum and bimetallic. The coolant is supplied through pipes. Despite the interesting design and properties of aluminum and bimetallic batteries, many opt for cast iron radiators.

Content

- Efficiency of a cast iron radiator in a heating system

- Factors Affecting Heat Transfer of a Cast Iron Battery

- Methodology for calculating the surface of a heating device

- The concept of temperature pressure

- Regulation of the coolant temperature at the boiler outlet

- Useful video

- Optimization of thermal power

Efficiency of a cast iron radiator in a heating system

When calculating the heating system for a room determine the required surface area of the radiator, accepted for installation.

Photo 1. Cast iron heating radiator. The device is decorated with decorative forging, suitable for a modern interior.

Manufacturers offer different types of devices that differ in:

- type of material used (cast iron, steel, aluminum and other metals and alloys);

- design features;

- standard sizes;

- the presence of auxiliary devices.

Cast iron radiators were standardized back in the middle of the last century., but even now manufacturers offer various innovations in design.

Factors Affecting Heat Transfer of a Cast Iron Battery

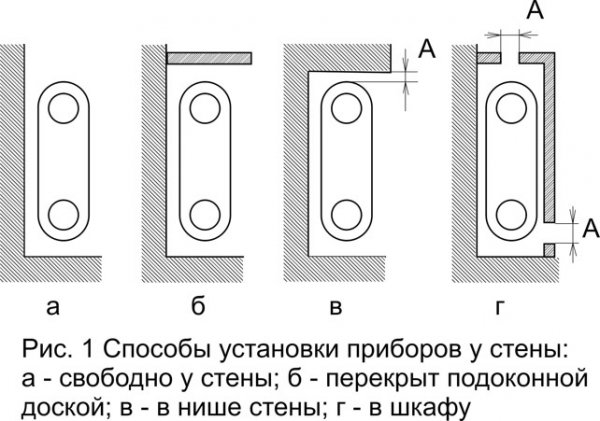

When installing the radiator freely against the wall heat transfer is maximum (Photo 2). A free convective flow is formed around the surface of the heating device, which transfers heat from the surface (tpr — device wall temperature, °C) to the air (tV — air temperature, °C) indoors.

Photo 2. Installation diagram for cast iron radiators. A total of four device layout options are shown.

Installing a heater under a window sill and a small distance between them slightly reduces the speed of free convection.

When installing a cast iron radiator in a wall niche heat transfer is somewhat reduced, since the intensity of the free convective flow decreases due to the resistance that arises.

Important! Increasing the distance between the lower edge of the niche and the radiator increases heat transfer.

When installing a heating device inside a decorative cabinet heat transfer is even lower, the cabinet itself and the protective nets provide noticeable resistance to the movement of the air flow. Therefore, the calculations include the values of the correction factors coefficients β1They take into account the reduction in the efficiency of convective heat exchange between the radiator surface and the internal air.

To reflect the heat flow into the room, they place it on the walls. foamed polyethylene with aluminum foil (foiled polyethylene).

The use of such a device reduces heat loss in the area where the heating device is located.

In table 1 The values of the coefficient characterizing the method of mounting a cast iron radiator against a wall are shown.

Table 1

Values of the coefficient characterizing the method of mounting the device against the wall:

| Method of installing a radiator against a wall | The value of the coefficient β1 | |

| foil-coated polyethylene is absent | foil-coated polyethylene available | |

| Freely by the wall (Photo 2.a) | 1.00 | 0.97 |

| Covered by a window sill at a distance A ≥ 100 mm (Photo 2. b) | 1.02 | 0.98 |

| Covered by a window sill at a distance A = 40…100 mm (Photo 2. b) | 1.05 | 1.01 |

| In a niche, the distance from the device to the lower edge of the niche A ≥ 100 mm (Photo 2.c) | 1.07 | 1.02 |

| In a niche, the distance from the device to the lower edge of the niche A = 40…100 mm (Photo 2.c) | 1.11 | 1.08 |

| In a wooden cabinet (Photo 2. g) with gaps in the top board of a width A = 150 mm and a gap at the bottom | 1.25 | 1.15 |

| In a wooden cabinet (Photo 2. g) with gaps in the top board of a width A = 180 mm and a gap at the bottom | 1.19 | 1.10 |

| In a wooden cabinet (Photo 2. g) with gaps in the top board of a width A = 220 mm and a gap at the bottom | 1.13 | 1.09 |

The methods of laying pipelines have an additional effect. Open laying increases the flow of heat into the room, closed laying does not have a noticeable effect on additional heat flow. Coefficient β2 evaluates the method of laying pipelines and the type of coolant supply system. When using a single-pipe system with an open method of laying β2 = 1.04, with a two-pipe system - β2 = 1.05.

Methodology for calculating the surface of a heating device

The surface area of a cast iron radiator is determined by the formula:

Fpr= ((Fpr - Ftr)β1 β2)/(kpr (tpr - tV)), m2, (1)

Where Fpr — heat transfer from a cast iron radiator, Tue;

Ftr — heat transfer from supply pipes, Tue;

kpr — a coefficient characterizing heat transfer from the coolant to the air inside the room, W/(m2*°C).

Heat flow from pipes laid openly inside the room, calculated using the formula:

Ftr= ∑ Ftr ktr (ttr - tV )η, W (2)

Where Ftr = πdl — the surface area of the pipe section, m2;

d — diameter of the pipe section, m;

l — length of the pipe section, m;

ttr — the average value of the coolant temperature in the pipe, °C;

ktr — coefficient of heat transfer from the coolant to the air, W/(m2*°C);

η — a coefficient that takes into account the location of the pipe in space (for vertical pipes η = 0.5; for horizontal ones - η = 1.0) .

After determining the surface area of the heating device, the number of sections is calculated. The formula used is:

n=Fpr/fsection , pcs, (3)

Where fsection — the surface area of a section of a cast iron radiator of a certain brand, m2 (Table 2).

Table 2

Basic information about cast iron radiators:

Photo 3. Table showing the dimensions, surface area and weight of different brands of cast iron radiators.

In large rooms, it is often necessary to install not one battery, but several. In this case, the presence of windows is taken into account. The batteries are placed under the windows. Then the number of sections in one cast iron radiator will be:

nbat=n/nOK , pcs., (4)

where nOK — number of windows.

The concept of temperature pressure

The calculation takes into account the average values of the coolant and air temperatures inside the room. For different heating systems, these values can vary within fairly wide limits. When installing a single-pipe heating system (for small residential buildings) Δt (temperature pressure, Δt = tpri - tV , °C ) on each i-th device will decrease.

Often decrease in value Δt are taken proportional to the number of sections of cast iron radiators used in the system. It is considered that each section of a cast iron radiator of the models M-140 (M-140-AO) reduces the coolant temperature by tsn = 0.25…0.38 °C. Model radiators RD-90, B-85 lower the temperature by tsn = 0.19…0.28 °С. Therefore, for each individual battery The decrease in the coolant temperature is calculated as:

tat=t1 - nsection i tsn , °C, (5)

Where t1 — the temperature of the coolant at the outlet of the boiler, °C;

nsection i — the number of sections up to the calculated battery for a one-pipe heating system.

Respectively, the temperature difference in the i-th battery will be determined:

Δti= tat - tV, °С. (6)

For two-pipe systems, the change in the coolant temperature in each battery is affected by the temperature drop in the supply pipes. For small buildings, these losses are insignificant. Therefore, they are often neglected in calculations. It is believed that the temperature difference is determined as:

Δt= (t1 - t2)/2 - tV, °C, (7)

Where t2 — temperature in the return pipeline, °C.

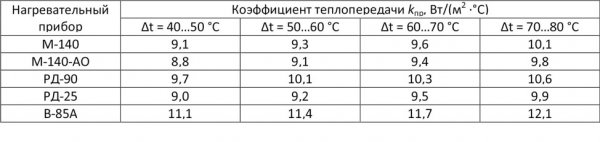

Attention! From the magnitude of the temperature difference Δt the heat transfer coefficient depends kpr (Table 3).

Table 3

Heat transfer coefficient values for cast iron radiators:

Photo 4. Table showing heat transfer coefficients of cast iron heating radiators of various brands.

Regulation of the coolant temperature at the boiler outlet

During the heating season, the outside temperature drops to critical values only for a few days. Therefore, it becomes necessary to regulate the parameters of the coolant at the outlet of the boiler. By decreasing this value, the magnitude of the temperature difference Δt is reduced.

It can be difficult to establish the value for each case by calculation. Therefore, special tables are compiled in which it is proposed to adjust the temperature t1 depending on external conditions.

Important! For each specific building, as well as the heating system, experimentally a table is compiled for the desired temperature value coolant at the outlet of the boiler t1.

The table is used, based on the weather forecast for the coming hours or daysThis allows to reduce the overall fuel consumption during the heating period.

The operating conditions of buildings and heating systems in them depend on a number of other factors.

That's why install temperature sensors inside the roomThey are associated with boilers.

The presence of such a connection helps to maintain comfortable conditions. in every room.

Useful video

Watch the video to learn how to increase heat output from cast iron radiators.

Optimization of thermal power

Correct installation of a cast iron radiator indoors allows to provide better conditions for heat exchange between the coolant in the heating system and the air inside the room.

Optimization of the heating system, carried out by competent selection of heating devices and operating conditions, allows you to maintain comfortable living conditions inside the premises and other types of activities.

Using Boiler Control Systems allows you to stabilize the temperature inside each room under different external conditions.