Harvest several times a year is not a fantasy! Boilers for heating greenhouses

For heating greenhouses different types of heating are used: from stoves to modern gas boilers. Constant heat ensures a normal microclimate inside the greenhouse.

Thanks to this, the harvest is higher, and it becomes possible to harvest it not just once, but two or three times a year.

Content

Methods of heating a greenhouse

To maintain the temperature inside the greenhouse minimum 25 degrees Celsius powerful equipment is required.

The peculiarity of its choice is that it is necessary to heat a fairly large area - sometimes up to 1000-5000 sq. m.

For this purpose, use:

- gas boilers;

- solid fuel stoves;

- electric boilers;

- diesel and combined models;

- IR heaters.

Reference. The cheapest option in terms of maintenance is gas boilers. Having spent money once on the purchase of the device itself, in the future you will have lower costs for utility bills for gas, maintenance and repairs.

Diesel fuel and electricity — expensive ways to heat a large greenhouse area. Coal, firewood, sawdust, briquettes are slightly cheaper, however, they need to be constantly purchased, brought in and laid manually.

Power of gas heaters for greenhouses with an area of up to 400-600 sq. m should be not less than 40-60 kW. This is quite a heavy piece of equipment (from 100 kg), which is often controlled by automation.

Air

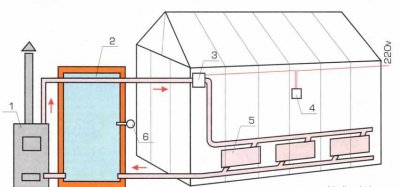

This method of heating is commonly used using solid fuel stoves. A "potbelly stove" can be used as a stove, which is installed outside the greenhouse and connected to a pipe for removing flue gases. To ensure uniform heating of the room, a horizontal chimney is made along the length of the greenhouse.

Photo 1. Air heating of the greenhouse: several convectors are installed around the perimeter of the room, which heat the air.

For air heating they use:

- electric, gas boiler, stove or regular fire outside;

- Heating elements/convectors;

- radiators and blowers.

Sometimes air heating is also considered infrared heaters, which are mounted in the walls or ceiling of the building. They are completely dependent on the electrical network, but are capable of heating a large area of the greenhouse.

It is also considered airy air heating with heat pump (a temporary way to solve the problem), as well as heating with steam, which is supplied inside the table through external pipes and returns back to the boiler through other underground pipes.

Advantages: easy installation, volumetric air heating (from below, from above, from the side).

Flaws: low efficiency, sometimes dry air.

Water

Involves water supply through radiators and pipes along the walls or in the center of the greenhouse. Due to this, a large area of the room is heated. This can be a single-pipe layout or other types of piping layout.

The heat source is a boiler (usually gas, electric or solid fuel), to which the pipes are connected.

For water heating use:

- chimney for waste disposal;

- automatic coolant addition system (to maintain a constant temperature);

- external and internal pipelines, boiler.

Hydronic heating may well work due to natural circulation of water. You can buy a pump and use it as needed.

Reference. It is best to choose cast iron radiators or bimetallic, aluminum devices, which easily connected to the heating system.

Advantages: Possibility of installation by yourself, heating not only the air, but also the soil.

Flaws: not suitable for large areas.

Types of heating boilers

Exists several varieties boilers that can be used to heat a greenhouse.

Gas. How to connect registers correctly?

Gas boiler consists of different components, in particular a steel or cast iron heat exchanger, an atmospheric burner (sometimes), a control system, a water circulation pump, an expansion tank and a safety valve.

Photo 2. Gas boiler for heating a greenhouse. The device is quite large, often it is located outside the greenhouse.

The device is working based on natural or liquefied gas, is undemanding to water quality and can be installed anywhere in the greenhouse.

Technical characteristics of the greenhouse boiler:

- Efficiency minimum 93%;

- power — from 40 kW;

- volume of water in the boiler — minimum 6 liters;

- height of the device about a meter;

- width - 54-60 cm;

- length - 90 cm;

- gas consumption - minimum 5.0 cubic meters/hour.

After the boiler is turned on, the water flowing through it is heated in the heat exchanger to the required temperature and is fed into the system circuit by the pump. This single-circuit option, which is used only for heating. To heat the greenhouse and supply hot water, use dual-circuit devices with a built-in hot water heating circuit. Single-circuit models are mainly used for greenhouses. Smoke is removed through a specially equipped chimney or through a steel pipe.

In order to connect the register to the water circuit, it is necessary to find out where the hot water will be supplied and where the cold water will leave from. Then, at the ends of the register, threaded coupling holes, to which they are then attached fitting, connecting the heat exchanger to the water circuit. On the opposite side from the feed, a air ventIt can be located at the end, but it is better for the valve to be at the top.

Since the register is very heavy, it is necessary to provide reliable fastenings. There are two ways of placement heat exchanger: wall and floor.

In order to install the register on the floor, it is necessary to make legs and also additionally fix the device to the wall.

Also, do not forget that the distance from the surface of the register to the walls and floor should be about 25 centimeters.

Advantages: The gas boiler is easy to maintain and does not require constant human intervention. It heats up instantly and ensures uniform heat distribution inside the greenhouse.

Flaws: high price for models for heating large areas, gas supply costs, need to coordinate boiler connection.

Solid fuel or pyrolysis

These heaters are also called pyrolysis heaters. They require any wood. There is usually plenty of such fuel in rural areas, and therefore this type of greenhouse heating is popular there.

For a solid fuel boiler use:

- wood (including dry branches, sawdust or regular firewood);

- compressed wood pellets or coal;

- straw, sawdust, wood waste, etc.

Important! Most boilers require fuel loading. twice a day, that is, to service the greenhouse, someone must be nearby at all times.

Advantages: low price, environmentally friendly fuel.

Flaws: necessity fuel preparation and its regular loading by the stoker.

Electric heaters

Mains powered heaters are the easiest way to heat a greenhouse. You can install the device anywhere in the greenhouse and quickly change the location if desired.

However, it is not profitable to install electric heating for a greenhouse if there are power outages in the region.

In winter, a sudden power outage can easily lead to the death of plants.

Advantages: mobility of the structure, possibility of work at any time of the day.

Flaws: device connection to the network, dry air.

Diesel

Diesel engines running on diesel fuel are not a relic. consist of a diesel burner, fuel filter and pump. Diesel fuel enters the burner, mixes with air and is sprayed by a fan. As a result, ignition occurs, and the boiler heats up. Such devices are controlled by a remote control. The boiler may have temperature control sensors for ease of use.

A diesel boiler is characterized by:

- the presence of a chimney for removing decay products;

- the ability to not only heat the greenhouse, but also heat water;

- fuel consumption - power kW/10 = kg of diesel fuel per hour;

- steel or cast iron heat exchangers.

Like gas boilers, diesel units can be traditional and condensing.

Important! Diesel boilers will need regular maintenance, as soot and ash accumulate in them. If the device is not cleaned, fuel consumption will increase and the heating temperature of the greenhouse will drop. Preventive maintenance is required once every 6-12 months.

Advantages: low price.

Flaws: minimum purchase 3-4 tons diesel fuel for the winter season, a large amount of waste in the form of soot.

Waste oil devices

Devices running on waste oil demonstrate high efficiency. They are perfect for rooms with high ceilings. from 3 to 8 meters. Used engine oils, regular kerosene, rapeseed oil, and sunflower oil can be used as fuel.

Parameters of waste oil boilers:

- average waste consumption — 1.5 to 8 l/h;

- large heating area: up to 1000 sq. m;

- power from 15 kW;

- combustion chamber wall — 6 mm, thickness of the outer part — 2 mm.

Inside the boiler there is a gear oil pump, a blower fan, an automatic control unit. Smoke tubes are used to remove waste.

Advantages: low cost, minimal maintenance, wide choice of fuel.

Flaws: the need for additional fuel purchase and storage.

Combined

Combined options are also used for heating greenhouses, which operate on different fuels. You can buy a unit that uses electricity and solid fuel in the form of wood or gas and coal. This allows you to change the heating source of the greenhouse and save money, for example, on gas or electricity.

Parameters of combined boilers:

- power minimum 21 kW;

- heating of a medium-sized greenhouse: up to 200-400 sq. m;

- spacious firebox for solid fuel;

- sealed boiler doors.

The main fuel for such a unit is firewood, coal and fuel briquettes. Additional fuel depends on the selected model.

Solid fuel you need to buy and constantly add moreso that the heating of the greenhouse is not interrupted for even an hour.

On such devices it is possible to install electric heating element And thermometer to determine the water temperature. Like solid fuel boilers, combined models need to be cleaned of ash regularly.

Advantages: long operation on different types of fuel, low price.

Flaws: large size and weight of the boiler, the need for constant monitoring of the availability of fuel, low efficiency (at 80% level).

How to choose

When choosing a boiler, you need to focus on the area of the room. Usually, they start from the following parameters - for 1 sq. m greenhouses need a minimum 120 W (with ceiling heights of three meters). This means that the power of the boiler or other equipment must be quite large.

Recommendations for selection boiler for greenhouse:

- high power and high efficiency of the device;

- ease of maintenance and minimal human control;

- affordable fuel;

- easy installation equipment in the greenhouse itself;

- simple chimney arrangement or a stovepipe;

- 100% waste removal outside (otherwise the plants may die);

- possibility of creation mild microclimate inside the greenhouse;

- optimal price on the boiler itself and its maintenance.

Reference. If there is no time to service the heating system, it is better to choose gas and electric models boilers. They are much more expensive, but these costs are justified.

If you live near a greenhouse and it is small in size, then you can easily get by with boilers or stoves where you need to put firewood.

Making a greenhouse boiler with your own hands

The boiler is being manufactured in several stages.

Selecting a project

If you decide to install a gas boiler in your greenhouse, need to prepare a project, on the basis of which the installation work will be carried out.

IN package of documents includes a thermal calculation of the premises, documents for the purchased gas equipment, diagrams of the location of the heating system in the greenhouse, drawings and much more.

For construction greenhouse boiler required:

- choose the place where the boiler will be installed;

- decide on the type of boiler (calculate power, select the type of draft, fuel);

- select a model, materials, tools and prepare them;

- order a project and obtain permission to install a boiler;

- install, test the boiler in test mode and start it up.

Easier order documentation preparation from a trusted company, which has experience not only in releasing projects, but also in obtaining permission to install a boiler from government agencies.

Materials and tools

The installation of a gas unit does not require any special construction costs. But if you decide to install the device yourself, you will need a lot of materials: from stainless steel to ordinary brick.

For a small greenhouse up to 20 sq. m Heating from a stove made of brick or other stone will be quite sufficient.

It is easier to make a regular solid fuel boiler from a metal barrel with holes for a chimney, drain and tank or a gas cylinder cut into two halves.

You will need:

- coil or water circuit;

- valves;

- loops;

- metal handles, etc.

For further maintenance of the solid fuel boiler The following tools are used:

- steel brushes;

- fire starters;

- Cleaning kits.

For other heating systems, tools are almost never used: The preventive maintenance is carried out by a specialist.

Construction and connection

If you still decide to build it yourself, you can use the most popular method among farmers.

Barrel or cylinder placed in a metal stove and a chimney pipe is mounted to it, which will remove waste outside the greenhouse. Then all that remains is to lay the pipes and weld them together. The pipes can be either metal or plastic.

Reference. If you live in a sunny region, you can install it yourself solar batteries. To do this, you will need a heat insulator, regular cellophane film, sand and soil. Due to such a simple design (the heat insulator and film are simply covered with sand and soil), the heat in the soil is retained for a long time.

No permits from government agencies are required to install solid fuel boilers.. You need to choose a ventilated room, make an opening for the chimney, install the boiler and connect it to the pipe, secure the heating radiators, expansion tank, and also install the supply pipeline and bypass for the pump.

Next, the pressure main is connected to the heat accumulator, the emergency circuit is started and the return pipeline is installed. After all work is completed, fuel is poured into the system, the pumps are started and the equipment is checked.

Attention! To connect a gas boiler to the heating system, you need to Be sure to call a technician. Independent work in this direction is strictly prohibited!

In this case, as noted above, it is necessary permission to connect to the external network and a special project. Only with these documents is it possible to connect gas equipment to the network. The work will require taps, valves, mud traps and other parts.

Possible problems with a homemade device

When building a pyrolysis boiler, the following difficulties may arise: uneven heating greenhouses or poor soil warming.

To prevent this from happening, you need to think through the laying of pipes and monitor the constant supply of fuel.

It is important to provide the possibility of minimal heating of water so as not to water plants with ice-cold water in winter.

Another problem is from electrical or simply excessive heating. the air may become too dry, which certainly affects the shoots. It will be necessary to constantly maintain a humid microclimate by watering or change the heating system.

Useful video

Watch a video that tells how to convert a potbelly stove into a boiler for heating greenhouses.

In case of a breakdown, call a repairman

For heating the greenhouse special equipment required. On the one hand, it should provide heating for a large area, on the other hand, it should maintain optimal humidity for plant growth. Heating should be uniform and voluminous, so that even the soil in the greenhouses warms up.

Photo 3. Gas heating boiler installed in a greenhouse. A water circuit runs from the device, through which water flows, heating the room.

Choosing a heater depends on the area of the greenhouse and the owner’s budget. Gas boilers cause the least problems, but they are expensive. The most affordable in price are considered to be water heating systems and solid fuel furnaces.

If the heating boiler starts to work intermittently, make noise, or suddenly turn off, Be sure to call a technician to fix the problem.

Comments

To grow cucumbers, I simply stuff the grass into a dug trench under the bed, water it and add a couple of shovels of manure to start, and cover it with 30 cm of soil on top. And when the grass starts burning, the soil will be warm, the main thing is not to overdo it with manure.