And in the most severe cold it will not fail! Wood boiler for a greenhouse, which one to choose

For year-round To obtain fresh vegetables and herbs in your own greenhouse, you must first think about how to create conditions suitable for growing and ripening plants.

The most obvious option is connect the heating system. Any boiler will do – running on gas, electricity and solid fuel.

Let's take a closer look at the last heating option.

Types of solid fuel boilers for greenhouses

It can be highlighted three types of the most convenient devices for use in greenhouse conditions:

- direct combustion units;

- pyrolysis boilers;

- long burning devices.

Pellet and direct combustion wood

Direct combustion solid fuel boilers are a classic example of a stove. Their device is extremely simple. — most often it is a combination of a combustion chamber, an ash accumulation chamber and a chimney.

Installation and operation of such a device will not cause any problemsThe boiler emits heat when burning wood with high humidity, dry wood, coal, peat briquettes, pellets.

Often such boilers are connected Heating elements for operation from electricity or connects water heating system. It all depends on the specific model.

The advantages of such devices include the price.. Due to the simple and clear design, as well as the lack of multiple electronics, such a boiler is not too expensive. The device will not depend on the availability of gas and electricity. So if there is a power outage somewhere, the unit will not stop functioning.

The need to stock up on large amounts of fuel refers to the disadvantages of the design. Wood, peat and other heat sources are not the cheapest materials, and you will have to pay for their periodic delivery. You will need to allocate space for storing "firewood", because not all models can accept raw materials.

Pyrolysis

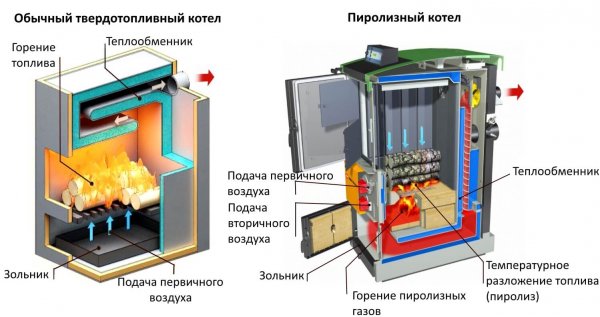

Pyrolysis boilers, also known as gas generators, work on a different principle. If a standard unit burns solid fuel, releasing soot, coke and ash into the surrounding space, then a pyrolysis boiler burns not only the wood itself, but also the gas that is released from the wood under high pressure and temperature. Subsequently, the gas is passed through a special nozzle, at the exit of which the flame is close to white.

Milky color of fire indicates a fairly high combustion temperature, therefore, the efficiency of the same amount of firewood used in a pyrolysis device and a direct combustion boiler will be completely different. Thus, the gas generator unit is a cut above its predecessor.

Photo 1. Comparison of the structure of a direct combustion solid fuel boiler (left) and a pyrolysis boiler (right).

Pros: Boiler efficiency. Much more heat can be obtained from the same volume of fuel, therefore, the costs for the fuel itself will be somewhat lower, which will allow the device to pay for itself. The environmental friendliness of this unit will be approximately three times higher, than in a direct combustion design, since water vapor mixed with carbon dioxide is released into the atmosphere.

The downside is the price. It may scare off an inexperienced user: the simplest units cost minimum 30 thousand. But the price of such devices justifies itself, and over time the device pays for itself through fuel savings.

Long burning on wood

These devices can be both pyrolysis and direct combustionThe average operating time of a long-burning pyrolysis boiler is about 8-10 hours on one tab. For full heating of the greenhouse Two bookmarks per day are enough. When the boiler goes out, the generated heat circulates in the room for some time. Therefore, if the greenhouse is insulated, the temperature will drop much more slowly.

A direct combustion boiler differs from a standard unit. The main difference is in the patented combustion and air supply system, in which the top layer of wood burns, constantly falling down. On one wood load, such a boiler will work for about 30 hours. On coal - up to 7 days.

Pros: Very large savings on fuel. No other type of boiler can compare in terms of performance with this unit.

There is no need to constantly monitor the temperature in the greenhouse and add firewood to the firebox.

Cons: The price, however, any amount paid for this boiler will pay for itself very quickly.

Fuel

Fuel is one of the most important issues when equipping a greenhouse with a solid fuel boiler. The main "suppliers" of heat are:

- firewood;

- coal;

- pellets.

Firewood

The standard requirement for firewood is that it must be dry. Some direct combustion boilers can use raw wood as fuel, but The efficiency of the unit will decrease. This, in turn, increases the amount of fuel burned.

Attention! For all types of boilers it is necessary to use firewood from birch, aspen and other species, resin freeDuring the combustion of coniferous wood, resin particles settle in the combustion chamber and chimney.

One log will not lead to fatal changes, but if you constantly heat the stove with pine needles, then the chimney will very quickly become clogged with resin residue and will not be able to pass the required amount of exhaust gas. Cleaning the chimney pipe will become a long and difficult task, and if you hire workers, it will also be very expensive.

Coal

It is preferable to use black coal, if possible - cokingThis will simplify the procedure of cleaning the boiler combustion chamber and will allow you to extract maximum benefit from the loaded fuel.

Brown coal can be used, of course, but highly not recommended. And not all devices can operate for a long time on this fuel.

Black coal before loading into the boiler must be dry And have approximately the same configurationIf the coal formation is too diverse, then small pieces will burn out quickly, and large ones will not be able to generate enough heat, which will require additional fuel loading.

Pellets

Pellets are made from peat and wood waste and their combustion properties are close to coalThey look like granules.

When choosing this fuel, you need to pay attention to the price of the product. Thanks to the pellet pressing technology are not afraid of moisture at all, so you can safely store them in the open air.

Pellets are accepted by all types of boilers (with the exception of some models), so they can be considered an effective source of heating for a greenhouse.

Photo 2. Pellets for solid fuel boilers. They are small pressed granules from wood waste.

Factors for choosing a solid fuel boiler

Before installing a boiler in the room, There are some points to consider:

- Climate zone. Since the greenhouse is heated in the winter months, it is necessary to review the statistics of previous years and clarify the average temperature in each month. This will allow you to see the extremes of temperature fluctuations and choose the most profitable option for the boiler and fuel.

- Greenhouse material. If the main light-transmitting material is a simple film, then the plants will not survive severe cold, no matter how actively the boiler works. If glass or polycarbonate are used, then the chances of getting a harvest are much higher.

- Fuel availability. If the nearest coal mine is hundreds of kilometers away, using coal as the primary fuel can be costly. In addition to the cost of the product itself, logistics costs will be added on top, and the price may be higher than that of gas and electricity.

- Area of the premises. For a large greenhouse (approximately 400 sq. m.) you will need either one powerful boiler or two. If the partitions are transparent, it is better to take two devices for optimal temperature maintenance on the outskirts.

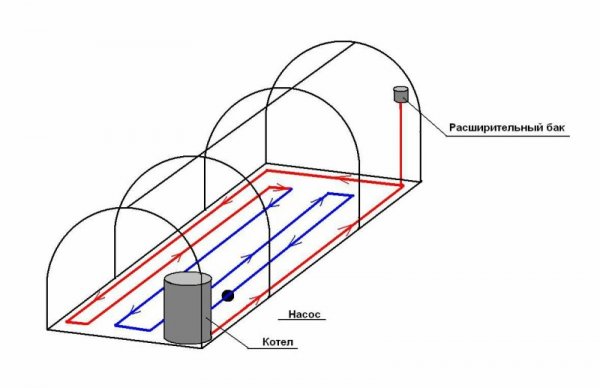

Calculation of requirements for technical characteristics, greenhouse heating scheme

The first thing you need to pay attention to is — this is the area of the greenhouse. Second — the presence or absence of insulation in the heated room. Third — availability of time to control the maintained temperature and load fuel into the boiler. Fourth — budget.

Photo 3. Greenhouse heating scheme using a solid fuel boiler and a water circuit.

Based on these requirements, you need to choose both the device and the fuel for it. With a small budget for a small greenhouse with thermally insulated walls, a direct combustion boiler is quite suitable.

For premises in 100-150 sq. m with insulation, and also with an average budget, a simple pyrolysis boiler will do.

A long-burning device is suitable if you have good initial capital and a large area (about 400 sq. m.) with insulated walls. In this case, minimal efforts will be enough to maintain the temperature regime.

Useful video

Watch the video, which demonstrates the principle of heating a greenhouse using a solid fuel boiler Vikhlach.

Conclusion

Correct Storing and preparing fuel will help you save on heating. Firewood and coal should not be larger than half the combustion chamber of the boiler, otherwise there will be no combustion, but smoldering. To prevent the fuel from getting damp, it should be stored in a dry, ventilated room.

Comments