If there is no gas or electricity, they will save you! Furnaces with a water circuit for heating the house

Home stove with water heating circuit allows you to heat your home efficiently and evenly.

Its difference from conventional ovens is presence of heat exchanger, to which heating batteries are connected.

Content

Water heating system device

Heating system consists of the following parts:

- bake;

- heat exchanger;

- pipes;

- batteries;

- circulation pump (not always installed);

- expansion tank.

The heat exchanger register is being installed into the combustion chamber or chimney of the stove. It is made of metal that can withstand high temperatures and transfer heat well. Hot water from the stove flows through a system of pipes to the heating radiators. Then the cooled water returns to the stove.

The outlet pipe is placed at the highest point of the device, and the inlet pipe is placed as close to the floor as possible. Then the hot water will immediately flow into the pipeline.

Attention! If the pipe is not connected to the top of the heat exchanger, steam will accumulate in it. As a result, there is a possibility of water hammer, which capable of destroying the system.

In small houses, gravity is enough to move the coolant. But if the area is large or the second floor needs to be heated, they connect circulation pumpIt forcibly drives water through pipes in the desired direction.

The pump is powered by electricity. In case of power outages, a backup is provided. expansion tank for backup water drainage. Otherwise, the liquid in the heat exchanger will heat up excessively and the tank may burst.

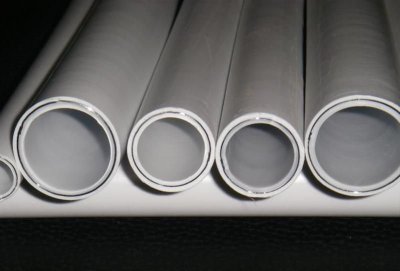

The pipes connected directly to the furnace are made of metal so that they can withstand the heat. The required diameter is at least 30 mm, and in large cottages - 40—50 mm.

The pipes leading from the stove to the radiators and from them are usually of a smaller diameter. up to 20 mm. The following materials are used:

- metal-plastic;

- polypropylene.

Sometimes the system is additionally connected hot water boiler.

Water is used as a heat carrier. To prevent freezing during the cold season, water is added. antifreeze or common salt. Also used glycerin fillerNot only does it not freeze in winter, but it is also harmless in case of leaks.

Attention! Sometimes, especially in summer houses, the water is simply drained before leaving and then filled again. But this is not only inconvenient, but also leads to increased corrosion of metal parts.

Types of stoves for heating a private house and their key differences

There are two types water furnaces:

- appliances for heating only;

- cooking and heating units.

From the purpose of the equipment depends on its design. In the first version of the stove, all the thermal energy goes to heating the house (through the coolant and walls). In the second, part of it is spent on the chambers for cooking food.

Regular wood burning stove

The stove differs from equipment used for traditional heating by the presence of a heat exchanger tank. It is manufactured:

- from sheet metal;

- from round metal pipes;

- from square metal pipes.

Photo 1. Metal wood stove with a water circuit. The firebox door is made of heat-resistant transparent glass, which allows you to admire the flame.

A heat exchanger made of sheets is easier to clean. But a tubular element has a larger surface area and therefore works more efficiently.

The resistor can be installed:

- into the combustion chamber;

- around the chimney.

In the first version it has U-shaped construction, located near the walls and ceiling of the chamber. The coolant heats up faster, but the tank material is exposed to higher temperatures and is therefore more susceptible to destruction.

In the second case, the air is not heated as much, and therefore it is required Larger volume heat exchanger. But it will last longer.

Reference. Most often, a tank for heating liquid is made from heat-resistant steel. But if it is mounted in a chimney, it is also used copperIts resistance to high temperatures is not sufficient for placement in the fuel chamber.

With cooking function

The dual-purpose stove design has certain features. The oven is located above the firebox. If you plan to use the stove for cooking, the heat exchanger are placed only on the sides of the firebox. Then the hot air rising upwards allows for the creation of sufficient temperature.

If the heat exchanger is mounted on all sides, the chamber will heat up significantly less. It will fit only for heating food.

In small ovens, sometimes a separate chamber is not made, but burner (less often - more than one).

It is not used as an oven, but as a small hob.

That is, you can use it to boil water in a kettle and cook food in small quantities.

Important! It is rational to use such stoves for cooking only in cold weather. It will be necessary to heat the entire system in the summer. economically impractical.

Recommendations for choosing a home wood-burning stove

Today there are quite a lot of types of stoves. When choosing ovens It is worth considering:

- area of the dwelling;

- preferred fuel type;

- the most suitable material.

Area of the heated room

The size of the building affects the choice of furnace power. For heating 10 sq. m at home it takes about 1-1.2 kW. This rule works for ceilings up to 2.5-2.7 meters, if they are higher, a little more power will be required.

For factory models of furnaces, this indicator is indicated in the passport. For homemade designs, it calculated approximately.

Fuel used

Water heating can work by burning:

- firewood;

- coal;

- fuel briquettes;

- peat.

All types of fuel differ in their characteristics. First of all, they give different amounts of thermal energy when burning the same volume.

But this is not the only thing that matters when choosing. The cost is important, as is how easy it is to find fuel in the area where the house is located. It is better to choose the type that can be purchased from several suppliers. The space needed for storage is also important.

Material

- brick;

- stainless steel;

- cast iron.

Brick ovens — the most massive. They require more space, and a separate foundation is installed under the structure. It is best to initially install a brick oven with a heating tank. Sometimes it is added later, although this requires dismantling part of the masonry.

Such heating devices give off heat for a long time and evenly. If desired, they can accommodate large oven chambers, but they take a long time to heat up. You will have to find a specialist to lay the structure.

Cast iron stoves also heat up quickly and give off heat longer than steel. But cast iron is a more brittle and at the same time heavy metal.

Photo 2. Wood stove with a water circuit, made of cast iron. Heating pipes are made of copper.

They are very popular steel structures. They heat the coolant less and faster. Furnaces with water heating are free from the traditional disadvantages of metal devices. They give off heat not only during fuel combustion, but also for a long time after it.

For metal and cast iron stoves no separate foundation required. It is enough to protect the floor from the effects of heat and accidental sparks. For this purpose, refractory materials, for example, a metal sheet.

Reference. There are models with a firebox door made of heat-resistant glass. They allow you to admire the play of fire. The atmosphere in the room becomes more comfortable.

Factory models of furnaces are produced on legs with adjustable height. Thanks to this, they can be easily placed even on a not entirely level floor.

Placement of heating devices

There should be a distance of 10 m to wooden and other flammable partitions. not less than half a meter. When using protective screens, this minimum gap is significantly reduced.

It is important that there are no beams above (or below) the stove. When the device is used for cooking, it is convenient to place it in the kitchen.

If the stove is located close to the entrance, firewood or other fuel will not have to be carried far.

In general, the stove has a water circuit less demanding on the location, because the house is heated not only through the walls and the firebox door. First of all, it is heated by the radiators.

Useful video

Watch the video, which provides instructions on how to connect a stove with a water circuit to the heating system.

Advantages over a boiler

Water circuit structures combine advantages of stove and water heatingThey heat the room evenly.

One device can be used to maintain the required temperature throughout the entire house, even if there is more than one floor.

For work no electricity required (if a circulation pump is not used) or it is spent much less than in electric boilers. Gas is not used either., connection to which is not possible everywhere.

Comments

Considering such stoves for heating a house instead of gas or electric is not serious, but it seems quite realistic to install it into the heating system and use it when the gas or electricity is turned off. Many people have gas heating boilers, and they do not work when there is no electricity. The material costs of purchasing and installing such a stove seem to be expensive, but they will pay for themselves when the electricity is turned off and for a long time. Loss of health and defrosting of the system will cost much more.