An unusual but effective heating option - a fireplace stove with a water circuit

It is perfect for fully heating all rooms in the house. fireplace (stove) with a water circuit.

Such cost effective solution will allow you to heat all the rooms at once using a fireplace and radiators installed in each room, without the use of auxiliary means.

Content

Features of a fireplace stove with a water heating circuit for the home

To understand everything nuances this device, it is necessary to understand it in more detail.

Design

This unit is visually very similar to classical fireplace with the only difference being that its variety with a water circuit in the upper part of the firebox or in the walls of the stove itself is available heat exchanger.

The air circulates through the coil built into it. water selected as coolant. Coil connects to a closed-loop heating system consisting of radiators and pipes.

If the area that needs heating is quite large, then this scheme also includes circulation pump.

In the lower part of the firebox of a fireplace with a water heating circuit there is a grate that serves as an exhaust hood - grateIt allows air to pass through for burning wood and serves as a place for ash accumulation.

There is a firebox located under the firebox ash panIt is a pull-out tray and functions as a blower.

At the top of the firebox is located smoke collector, passing into the chimney.

This is a classic model of a fireplace-stove with a water heating circuit. Depending on the complexity of a particular model, there may be different pockets for hot air outlet and other elements.

There are also fireplaces in which water heating is carried out using a plate-type heat exchanger.

Material: cast iron or brick?

Source materials for a fireplace with a water heating circuit:

- Steel metal construction has comparatively light weight and low cost. Cons: susceptibility corrosion.

- Cast iron The fireplace is distinguished by its durability and resistance to rust. Disadvantages: big weight and intolerance to temperature fluctuations, which leads to cracks.

Best combine these two materials, using their positive sides. Thus, metal parts are mounted in the fireplace body and places protected from overheating. Cast iron elements are best mounted in the firebox: grate and doors.

It is also possible to make a fireplace from brick.

Properties

Basic properties of a fireplace with a water heating circuit

- usage natural fuels: wood and coal — the cost of both is quite reasonable;

- the design features of the unit allow heat large areas, while consuming the same amount of energy as a classic type oven;

- the possibility of using a fireplace with a water heating boiler in the design of a heating system gives a positive result: increased productivity;

- efficiency of thermo-fireplaces 35% higher indicators of a classic type furnace;

- fuel is loaded into a fireplace with a water heating circuit just a few times a day;

- The source materials used to form such devices have low and acceptable cost.

Advantages and disadvantages of long-burning thermo-fireplaces

The advantages of the design include the following:

- ease of use;

- Possibility of installation in premises with the presence of minimum fire safety rules;

- by the fireplace with a water heating circuit loyal price range;

- fixed electricity consumption indicator;

- usage inexpensive fuel;

- full autonomous operating mode;

- warming up large area;

- appearance does not spoil the design premises.

When purchasing such a design, you should also know about the disadvantages:

- Insufficient efficiency in severe frostsIn such conditions, it is better to use this type of heating as an auxiliary one.

- The unit's operation is not completely automated. You need to light a fire in the fireplace yourself.

Varieties

They differ depending on the type of firebox:

- Open type firebox. The heat goes out into the room, the heat output of such a fireplace is extremely small. It has more of an interior significance.

- Closed type firebox separated two metal walls, where the coil-shaped heat exchangers are located. When connected to the heating system of the entire house, such a fireplace will become an independent source of heating.

Photo 1. Fireplace with water circuit model Pryzma PL-190, efficiency 75%, manufacturer - "Lechma", Poland.

Connection systems

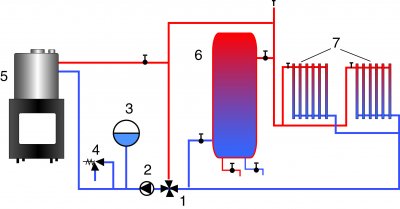

There is a basic process flow chart which includes:

- fireplace (mounted on the top floor or in the basement);

- radiators (water heated in the tank enters them);

- water tank (heat and hydraulic accumulator, installed in a technical room);

- coil (required for the passage of heated coolant from the heat accumulator).

Depending on the location of the tank, it is customary to distinguish two different schemes.

Open

With it, the capacity is installed at the highest point of the building, and the liquid goes into the heat exchanger under the influence of gravity. The excess heated water goes back into the tank.

The liquid is heated in a coil located in the furnace nozzle (its open boiler part). The installation of such a system will not cause any difficulties, but it is very impractical due to water loss, its specific gravity and other reasons.

Closed

In this case, the coil is located in boiler closed sectionWith the help of a circulation pump, the liquid passes into the storage tank, and then into the heating system.

Attention! To prevent the water from boiling and the device from failing, a firebox is mounted at the back of the firebox. additional coil for supplying (if necessary) cold water.

The main advantage of such a connection system is that the water jacket of the firebox contains special temperature sensor, at the signal of which the necessary water discharge into the sewer is carried out.

This connection system, unlike the first one, allows you to heat the premises large area.

Choosing a fireplace: corner or regular?

It is important to take everything into account Main design parameters:

- power rating (it is necessary to make a preliminary calculation based on from 1 kW per 10 m²);

- original material the fireplace itself and the heat exchanger (cast iron or steel, but it is better to consider combined type models);

- base under the fireplace (Formation is mandatory non-flammable foundations under the structure itself, this could be ceramic, iron base. For a metal or brick fireplace stove, it is best to make the flooring from asbestos sheets);

- long burning (There are fireplace options with a damper, and you can also find ones with a thermogenerator. Second option serves as an additional source of heat. Both varieties will allow you not only to heat water for food, but also to heat your home);

- fireplace functions with a water heating circuit (in addition to the main heating purpose, these units can act as a source of hot water supply for the house or a hob);

- designer decoration (there is a wide choice of fireplace stoves, so everyone can choose a device based on their own taste, home interior and financial situation);

- corner fireplace with a water heating circuit it looks very stylish, heats several rooms, has a wider view of the flame, takes up the non-functioning area of the room, has a high efficiency;

- manufacturers (most popular: german Schmid, Italian La Nordica and EdilKamin, Czech AVH, Finnish Harvia, Helo and Kastor, domestic Termofor, Ermak, Vulcan).

How to install it yourself

Initially, the design of the structure is thought out. For this, several points are taken into account:

- Size fireplace is determined based on the dimensions of the room. Thus, the unit should be the size 1:70 of the room area.

- Firebox depth

Important! The greater the depth of the firebox, the less chance of smoke getting in into the room.

- Height the chimney is from 4 to 8 meters.

- Original material constructions - brick. The quantity is calculated.

- Under development ordering — a diagram indicating the layout of brick rows.

- The back wall of the fireplace is protected sheet metal — for fire safety reasons.

After completing the calculations, we begin the main work:

- Formation of the foundation: into the hole to the depth 0.6 m The crushed stone is laid and compacted. Then the formwork is formed, roofing felt is laid, and the foundation is poured on top.

- Laying out a double layer of roofing felt on the frozen after 7 days foundation.

- Ordering bricks.

- Conducting finishing works (with materials you liked).

Useful video

Check out the video that shows how to install a fireplace with a water circuit yourself.

Operation and maintenance

Before starting the heating system, an inspection of all components is carried out; for the summer period, it is completely drain the coolant. The chimney is being cleaned at least twice a year, and the ash pit - regularly. The fireplace glass is treated with special solutions as needed.

Follow these simple rules and extend the life of your eco-fireplace with a water circuit for a long time.