An effective way to automate heating: the principle of operation and the device of a circulation pump for heating

Decide the problem of slow heating and reduce the cross-section of the main lines It's simple - just install a circulation pump.

This is a device that maintains constant orderly movement of the coolant inside the pipes and compensating flow resistance the system itself.

As a result, the boiler works with less load, the heating speed increases, the lines become more compact and invisible. And it is already possible to effectively heat a larger volume. Plus, the efficiency increases by at least a third.

Construction of circulation pumps in the house: how are they arranged?

The design of the circulation pump is not complicated. Car pump or drainage system work on the same principle.

There is an electric motor used as a drive and a turbine.

More precisely, a centrifugal impeller. The impeller is enclosed in a snail-shaped housing from which the two pipes.

One of the pipes creates a leak during operation underpressure, the other one has - compression.

Reference! In addition, each device has an electrical part responsible for switching and changing operating modes.

Two main types of devices for the heating system

Circulation pumps are distinguished according to working conditions. If the rotor comes into contact with the working medium, it is called wet. If the rotor is isolated from the pumped liquid, it is called dry.

Dry rotor operating principle

- Higher efficiency;

- able to work with contaminated liquid;

- fits for pumping large volumes;

- less sensitive to temperature changes.

The rotor is designed without active excitation (permanent magnet) and is in contact with the pumped liquid - the so-called wet. It is located in a separate glass, isolated from the electric stator.

Attention! The transported medium plays the role of lubrication and cooling.

Pros:

- simplicity of the device;

- relatively low price;

- long service life;

- silent operation;

- compactness.

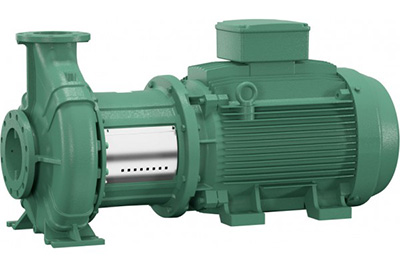

Photo 1. Circulation pump with dry rotor Wilo Crono Bloc-BL 50/220-3/4 with high efficiency.

Cons:

- low efficiency;

- the need for precise compliance with installation rules — the rotor is positioned strictly horizontally;

- sensitivity to cleanliness — abrasive impurities in coolants sharply reduce service life;

- increased noise;

- need for regular maintenance and shorter service life.

What mode does a wet rotor operate in?

Most often, wet rotor circulation pumps are installed in a private home. In this case, their low efficiency doesn't play a big role, since the final power consumption is low. Much more important are the silent mode, durability, undemanding maintenance and compactness.

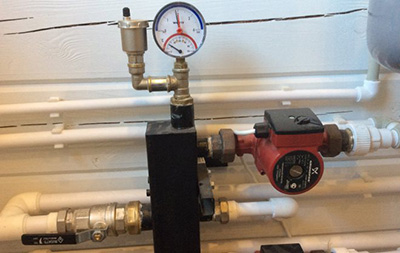

Photo 2. Wet rotor circulation pump Making Oasis Everywhere CN-22/2, compact and durable.

Connection Features

When connecting the device, it is advisable to take into account a number of recommendations. Following simple rules will increase the service life of the system, it should work more efficiently.

It is better when the flow created by the pump is oriented horizontally. When vertical directions efficiency drops by 30%.

As already mentioned, the motor rotor is located horizontally.

Otherwise, overheating and premature failure may occur. Compliance with this condition is mandatory!

It is better to install the device on the return line to reduce thermal stress.

In addition, it is worth installing before it mud filter — the rotor is sensitive to the presence of impurities such as scale, sand, and scale.

Important! During installation, a bypass line is provided - a bypass with a mandatory shut-off ball valve or automatic valve. This will allow changing equipment, without disrupting the operation of the system.

Shut-off ball valves are also installed at the inlet and outlet of the device in case repair or maintenance. They can be replaced with a single tap or automatic ball valve.

It is better to connect the supply line before the pump - its place is between it and the boiler.

Useful video

Video review of popular circulation pumps, their characteristics and operating principle.

What should be the efficiency?

The power consumption of such a device is low, but a solid debit accumulates over the year. Therefore, most models are equipped with a three-stage regulator, allowing you to optimally adjust the operation of the heating system.

In addition, modern designs provide for electronic power control, changing the impeller rotation speed depending on the coolant temperature. This makes the heating system more efficient.