What is the difference between closed-type heating systems with a circulation pump and open-type systems?

To ensure continuous circulation of hot coolant in the heating system and maintain a comfortable temperature in the house, They are installed near the boiler circulation pump.

It doesn’t matter whether it’s on the direct or return pipe, but before the branches. Most systems can withstand the temperature up to 115 °C, which is enough for any heating.

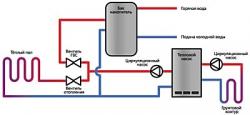

Circulation pump connection diagrams

The type of installation depends on the selected pipe and type of system. They also consider the diagrams for connecting electricity and additional equipment.

On serve

Installation on a direct pipeline is in low demand. Experts believe that it is better to choose the reverse one. This is due to for three reasons:

- The water temperature in the current case is much higher, but the pumps are able to withstand it up to 110-115 °C. At the same time, boilers installed in private houses do not heat the coolant even up to 90 °C.

- The density of hot liquid is lower, which makes it more difficult to pump. The difference at 20 degrees changes the indicator only 10 kg/m3, what for a quality device with pressure about 5 meters does not create problems.

- The pressure of the cooled coolant in the return line is higher, but the difference insignificant.

Therefore, the choice of installation location for the circulation pump depends more on convenience than on technical characteristics.

Attention! The only exception is solid fuel heaters. without automatic temperature control. When using them, the coolant it's boiling, which leads to damage to the device.

The installation location is gap between boiler (after the shut-off valve) and the first branch. In addition to the pump itself, it is necessary to install fasteners to facilitate dismantling and filters for protection.

On the return

The steam that is formed when the water temperature increases does not reach the boiler because it has time to cool down. Therefore, such a unit is used more often, especially when using solid fuel heaters.

It is recommended to install the pump at the point where the pipeline joins. in one after all the radiators. And also separate the shut-off valves. The further choice of location depends on the convenience of maintenance.

Typically the device placed in front of the heat generator, supplying dirt filter. It is advisable to place it on the metal part of the pipes for better temperature control.

To the open type system

Regardless of the type, the pump mounted horizontally, which reduces the noise generated. This is due to forced circulation, which in vertical devices takes longer to lift the water to the top.

Including the device in an open wiring does not bring significant changes. It is often placed on the return pipe, one and a half meters from the boiler. For safety, they install bypass and check valve, the latter being optional. The direction of water flow is also taken into account. It is possible to install filter for cleaning the coolant.

To a closed heating system

In a closed system, a circulation pump is also placed on the return pipe. The principle is no different from the previous one. The only remark is Installation of a check valve is mandatory. Otherwise, the normal flow of fluid through the piping is disrupted.

To the electric boiler

Electric boilers, like fuel boilers, work without problems with forced water circulation. It is enough to follow the pump installation rules, otherwise the efficiency factor will decrease.

It is recommended to look for a suitable place at the bottom of the harness, preferably — on the supply pipe.

For safety ground the system, but not to zero. Otherwise, the phases may become mixed up, causing a short circuit.

If the boiler is installed correctly, there should be no problems with the pump. It is enough to follow the installation instructions attached to the device. To install the system, you also need: a distributor, taps, a filter, a pressure gauge, piping elements and fasteners.

To the electrical circuit

Any circulation pump is connected to a power source for power supply. A separate line with a protective device is created. You will need three wires: for phase, neutral and ground. There are several connection schemes:

- through differentiation device;

- together with uninterruptible power supply;

- powered by a boiler (with built-in automation);

- With regulation of heat generation.

You can use the classic method - with with a regular fork, but in this case there is a high risk of an accident or fire.

First scheme It is used in most cases, ensuring the safety of wires and equipment. It is also quite easy to assemble by hand.

First they put differential circuit breaker, selecting the current strength and cross-section to suit the pump characteristics. Power is supplied to the upper part (odd numbers), load - to the bottom. Connectors for 0 are designated by the letter NTo automate the control process, thermostats are connected: one to the device, the second to the supply.

Important! To ensure that the devices operate on time, the controllers are installed on metal section pipes. This is due to the low thermal conductivity of plastic.

The circuit with the uninterruptible device is the second most popular. It has many connectors to which not only the pump but also the generator is connected.

For connecting devices powered by a boiler or with heat output regulation Contact professional electricians.

With additional units

In any system with one boiler, a pumping device must be installed. But in more complex layouts, additional ones will be needed. This happens in the following situations:

- when using two or more generators;

- when applied buffer capacity;

- if present multiple circuits or boiler;

- when installing hydraulic separator;

Photo 1. Heatmix model hydraulic separator with thermal insulation casing, connection thread - 1 1/2'', manufacturer - Grundfos.

- with a total length of pipes more than 80 meters;

- when using warm floor.

To create a proper system of several heaters on different fuels, it will be necessary to place backup pumps. In such a situation, the main line will be divided into two parts: heating and boiler. A buffer capacitor does the same thing, although there may be more circuits. Similar circuits implement in 3-storey and large houses.

As branching occurs, the pipes are broken into several independent sections, each of which is equipped with a pump. They evenly distribute the coolant across the floors. Regardless of the quantity, each is placed on a bypass. It is advisable to supplement them with ball valves to reduce consumption in the summer season.

When using heated floors, install two circulation pumps. A set of devices will help prepare the working fluid, heat it to the required temperature and maintain it.

To ensure sufficient power, the length of the harness should not exceed 50 metersOtherwise, the system operates unevenly.

Reference! When using some devices, pumps are not needed. This applies to wall-mounted electric and gas generators. The manufacturers install a forced circulation device into their design.

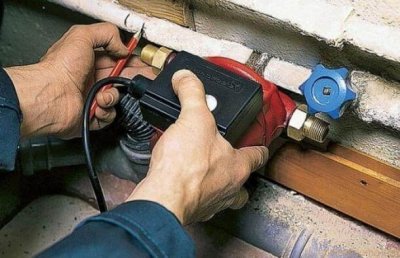

Features of installation in a private house

The installation is carried out according to the diagram attached to the pump. The principle is similar to that used during installation production devices. Choose a suitable place in compliance with the rules, the list of which depends on the type of device. Then, in one of the points with the most convenient service, place it according to the instructions.

Useful video

Check out this video that shows you the different types of circulation pump installations.

Conclusion

Install the circulation pump yourself not difficult, but for safety and uninterrupted operation invite specialistsThis is especially true for the installation of electrical components.