Why do we need this unusual unit? Purpose and principle of operation of the elevator in the heating system

The elevator unit performs several functions, providing consumers with heat.

With its help the coolant is distributed equally between all, regardless of distance.

Despite the fact that there are more modern models, the classic model of the device is still installed in homes.

Why do you need an elevator: the main purpose of the device

Initial parameters of the coolant at the outlet of the thermal power plant or boiler house: 105—150 °C, pressure 6-10 BarSuch high rates are necessary for:

- achievements maximum efficiency heating equipment;

- possibilities deliver coolant to areas that are very remote from the supplier;

- For economic benefit (a ton of water with a higher temperature contains more thermal energy than a ton with a lower temperature);

- preventing vaporization water.

When the liquid comes to the consumer through the pipes, it does not immediately get into the heating radiators. Its indicators for the in-house network are too high and dangerous. They need to be lowered.

The water temperature needs to be reduced up to 95 °C, reduce pressure. This requires SNiP 41-01-2003 "Heating, ventilation and air conditioning".

Reasons:

- hot water in radiators with temperature above 95°C, may cause burns to the consumer;

- intra-house pipes and radiators with such indicators may leak or explode;

- plastic pipes cannot be used at such high temperatures.

This is the main purpose of the elevator. It is a device that brings the coolant parameters to normal. This happens by mixing cooled water from the return heating circuit with hot water. In addition, it is a water pump.

Elevator functions

- temperature drop coolant;

- pressure reduction in pipes;

- ensures water circulation in the system.

Elevator - non-volatile device. No connection to the electrical network is required.

The principle of operation in the heating system

The body unit of the house is located, most often, in the basement. The elevator is installed in this unit between the supply pipes and the return circuit. He connects them.

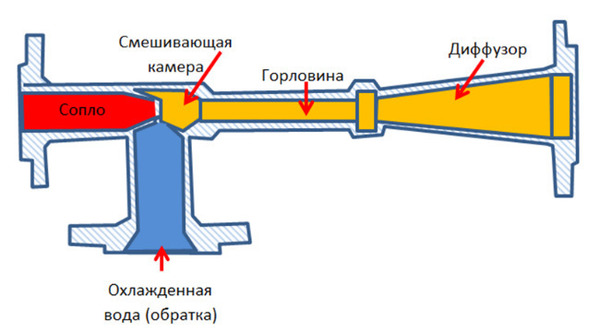

The material from which the mixing unit is made is cast iron or steel. Consists of 3 flanges. The operating principle of the device is based on the laws of physics. Water in the node goes through the following stages:

- Highly heated and under high pressure, it enters the nozzle., which has a cone shape, one end narrows. As a result, the flow rate of the coolant increases, but the pressure decreases. Here the elevator begins to act as a water-jet pump.

- Then, with reduced pressure, water enters the mixing chamber, where it mixes with the cooled one. The liquid comes from the return circuit from below. At this stage, the temperature and pressure of the coolant decrease.

- Next, through the pipes treated water is delivered to the consumer.

Photo 1. Schematic diagram of the elevator unit. The arrows indicate the components of the elevator structure.

The main condition for normal operation of the unit is pressure difference between the inlet line and the return circuit.

Attention! For uninterrupted operation of the elevator you need to install a harness, which includes: mud filters, inlet and outlet pressure gauges, temperature sensors and repair valves.

Useful video

Watch the video which explains why an elevator is needed in a heating system.

Pros and cons of the elevator unit

Advantages elevator:

- does not require connection to the power grid;

- inexpensive;

- simple in editing;

- does not take up much space;

- easy to maintain;

- works in the multi-apartment system houses.

These advantages allow the use of elevator units in most homes in our country for a very long time.

Flaws:

- A water pressure difference is required between the return and the inlet, which is difficult to provide.

- If the system is not standard, An exact individual calculation is required to select a model and installation of the elevator.

- When a non-volatile device is installed, then it is impossible to adjust the nozzle diameter. This means that the temperature cannot be regulated.

- For use only in a central heating system.

Elevator models are available in which the nozzle cross-section can be adjusted automatically. They require an electrical connection. With the help of such regulation, the temperature and consumption of the coolant are changed. But one of the main advantages is lost: energy independence.