The heart of the heating system: nozzles for a gas boiler. What are they, why are they needed?

Gas burner is a device where oxygen and gas are mixed, this mixture burns and forms a stable flame.

Nozzle – simple design, extremely reliable and efficientThere are several types of devices.

Content

What are gas boiler nozzles used for?

Gas burners are important part heating boiler. They are used for the preparation of a combustible mixture from gas and oxygen molecules taken from the air. The nozzle then continuously feeds the finished substance to special holes and ensures combustion. The result is a fiery torch. In addition, the nozzle can have additional equipment aimed at security, automation of work systems and ignition.

Photo 1. Gas nozzle in working condition. It is possible to regulate the boiler power.

Types of devices on natural or liquefied gas

Gas injectors are distinguished by the type of fuel, which is used in the system. They are for natural gas from the main line or for liquefied gas from a cylinder. They have different diameters and operating pressures. As a rule, burners for both types of fuel are included with the heating device.

Injectors are classified according to the operating principle of the device, how the gas-oxygen mixture is prepared, how the gas is supplied to the combustion chamber and some other features. Two main types injectors: fan or atmospheric.

Ventilators

The design of these nozzles is considered complex and includes a built-in fan and turbine, so they are also called forced-draft fan. Air is forced in and in controlled volumes, so the combustible mixture is prepared in strict proportions. A boiler with such a component is productive and economical. They are used in devices with a high degree of automation.

Important! This type depends on electricity. Without electricity, the gas supply will be cut off!

Pros fan nozzles:

- economical, reduce fuel consumption;

- combustion is under absolute control;

- power is adjustable;

- The efficiency is significantly higher than that of atmospheric ones;

- can be used in houses where there is no chimney;

- no need to reconfigure for another type of fuel.

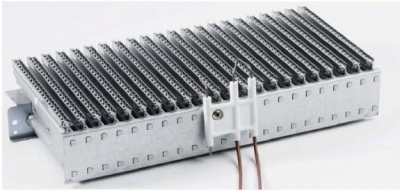

Photo 2. Fan-type nozzle for a gas boiler. The device contains a fan and a turbine for air injection.

Cons:

- high price;

- energy dependence on electricity.

Atmospheric

This type of equipment is usually used in floor-standing boilers for houses with an area of not more than 100 square meters. The power is set at the factory.

Reference. When changing the type of fuel reconfiguration required.

These burners take air for the preparation of a combustible mixture directly from the room where the heating device is installed, that is, from the atmosphere, hence the name. The atmospheric nozzle works on the principle of an elementary ejector. Gas under pressure is directed through specially shaped nozzles. These nozzles have access to normal air from the room, which is drawn into the system.

The finished mixture comes out through the slits., located a little further away, where the ignition occurs. The air becomes rarefied as it moves from the nozzle to the outlet, which creates a constant draft.

Pros atmospheric devices:

- simplicity of design;

- low price;

- noiselessness;

- safety;

- reliability;

- do not depend on electricity.

Cons:

- you can't adjust the power yourself;

- low efficiency;

- need a chimney.

Burners They are also divided according to the possibility of power regulation:

- Single stage - no adjustment possible.

- Two-stage — two modes of operation of the heating device.

- Smooth two-stage — allow a smooth transition from the first stage to the second. Something in between two-stage and modulating burners.

- Modulated version - There is a possibility of regulation within the range from 10 to 100 percent.

How to choose a device

To select the appropriate component for the boiler, it is necessary study technical specifications devices, find out the combustion power heating device.

It is better to consult a specialist. The most important factors when choosing are: power, range and control method.

First, select the nozzle according to its power. must exceed the boiler capacity, but not very significantly. The range of system power regulation will depend on this.

The injectors are selected according to the type of regulation based on the size of the roomFor a private boiler room with low power, any type is suitable, for industrial scale or for very large houses, systems with smooth two-stage or modulated regulation are needed.

Replacing the gas injector

Installation steps burners:

- Removing the old burner.

Photo 3. The process of dismantling the burner from a gas boiler. This work should be done exclusively by a specialist.

- Fastening of reinforcement.

- Nozzle installation.

- Connecting the electrical connector.

- Installation of a gas ramp to the main line.

- System start.

- Setting and adjustment.

Attention! Install components on the boiler Only a specialist has the right!

Materials and tools

To replace the nozzle in a gas boiler you will need a minimum of tools: instructions for the boiler and burner, screwdriver, soap solution and brush.

Preparing the site and dismantling the old structure

Dismantling sequence burners:

- close the gas supply valve;

- remove the nozzle from its mounting location;

- carefully unscrew it.

Preparing the site involves removing excess dust., ensuring free access to the boiler and supply of fresh air to the boiler room.

Fan Burner Installation Instructions

The first stage is extremely simple. The injector comes with all the fastening elements. You only need to check whether the gaskets are installed correctly in the fastening points.

Second stage It will also not be difficult if a suitable burner has been purchased.

If not, then replacement is necessary; it is strictly forbidden to operate the system with unsuitable components. The nozzle is installed in place so that the nozzle does not touch the walls of the hole in the heating device. Screws are screwed into the mounting holes.

The connector can simply be turned on, if the inputs on the boiler wires and on the burner match. Otherwise, the burner comes with a suitable connector, you need to replace the one on the boiler wire with it.

Important! Make sure that the boiler electrical circuit is compatible with the burner! The diagrams are provided in the description of the boiler and burner.

It is mandatory on the gas pipeline install a shut-off valve, to turn off the gas supply to the burner. The burner is connected to the pipe either using an anti-vibration coupling or a bellows pipe, since the turbine vibrates quite noticeably during operation, which leads to depressurization.

System startup and testing

The heating device is connected to the power supply, the valve on the gas pipeline is opened. The valve is turned for the first time to a minimum.

If there is a gas supply regulator, then it they put it on maximum. Then press the button on the dashboard. The fan turns on, blowing occurs and a spark appears, the gas ignites.

This can happen not the first time, because air accumulates in the system. If the burner is blocked, it is unblocked according to the instructions and started again.

To exploit boiler without adjustment it is impossible. It is better to perform the adjustment using a gas analyzer and special tables, but it is also possible by eye. To do this, look at the flame through a special viewing hole. The gas supply is gradually reduced so that the flame, instead of an orange hue, acquires a bluish color, this will be the optimal mode.

If you hear a humming sound when burning, then the flame length is reduced. Finally, check the system for leaks using soapy water. Apply the solution to the joints; if there are no bubbles, the system is leak-proof.

Useful video

Watch the video, which talks about the features of reconfiguring a gas boiler to liquefied gas using special nozzles.

Conclusion

The gas burner is the most important element of the boiler, its choice the durability and quality of the heating device depends. An incorrectly selected nozzle can significantly increase fuel consumption, damage the combustion chamber of the boiler and even lead to a gas leak. Work related to the installation and maintenance of gas equipment is carried out only by qualified specialists. Self-replacement of a gas burner is illegal and very dangerous.

Comments