Independent and simple heating setup: how to connect a boiler to a double-circuit gas boiler

Double-circuit gas flow-through boilers simultaneously provide heating and hot water supply (HWS) systems. Household models are not powerful enough for a family of several people.

For example, just one shower consumes up to 15 liters of hot water per minute, and domestic boilers give out only 13-15 l. If two or more consumers operate simultaneously, the DHW pressure will drop significantly.

The problem can be solved by replacing the boiler, but it will require permission from supervisory authorities. An alternative is to connect the boiler to an existing water heater. A boiler is a storage tank that stores heated water for DHW needs. It allows hot water to be supplied to several consumers at the same time under the required pressure, but it takes up a lot of space and, if connected incorrectly, poses a threat to human health.

Content

Types of double-circuit gas boilers with a built-in boiler: are they necessary?

Boilers are used together with single- and double-circuit gas boilers. In the second case, the unit itself only works for heating. freestanding and built-in boilers.

The first ones are often purchased separately, have a large capacity, are suitable for single- and double-circuit devices of open and closed type. Require complex connection.

Built-in tanks are part of ready-made solutions based on double-circuit boilers. Compact due to small volume, equipped with advanced automation from the factory, easy to connect.

Important! The volume of a separate boiler is selected proportionally to the boiler capacity. If the tank is too large, the water in it will not heat up to the required temperature. according to sanitary standards 60 °C. This is fraught with the appearance of dangerous colonies of legionella.

Modern devices with built-in storage tanks have an “anti-legionella” function: the boiler automatically warms up from time to time up to 65 °C for 30 minutes, thereby killing harmful bacteria.

Double-circuit gas boilers with water heaters differ in location, type of storage tank and its capacity.

By location: floor-standing, energy-independent and wall-mounted

Floor standing energy independent boilers are distinguished by their large size and high power. The mass of the heating device without liquid reaches 100 kg. Equipped with built-in boilers with a volume of up to 120 l, external wall-mounted or floor-mounted — 50–500 l.

Photo 1. Floor-standing double-circuit gas boiler with an indirect heating boiler, installed in a special room.

Often require placement in a specially equipped boiler room. They heat and supply water quickly, but sensitive to voltage surges. They create problems when connecting the recirculation system.

Wall-mounted equipment is smaller and weaker than floor-mounted equipment. It does not require a separate room, and can be installed in bathrooms and kitchens. It is usually equipped with built-in indirect heating tanks. capacity 10-60 l with constant heating of liquid by the secondary DHW circuit.

Less often they are connected to separate boilers of similar volume. Their heat exchangers have a small internal cross-section, which is why the devices afraid of scale and are very sensitive to water quality.

By type of boiler with electric heater

Direct heating boiler equipped with its own heating element, independently increasing and maintaining the water temperature. Often this is a tubular electric heater (TEN), powered by the mains or gas. Installation of the second option also requires permission from regulatory authorities.

The DHW system may be based solely on a direct heating storage tank, bypassing the connection to the boiler.

Indirect heating boilers do not have their own active heating element. The water tank contains coil, passing through itself a coolant, preheated in another heating device. They are installed with gas equipment with a capacity of from 25 kW, For the automation to work, a connection to the network is required.

Photo 2. A double-circuit gas boiler with a combined boiler heats the water in the tank due to the operation of the coil.

Combined boilers have a coil that operates on an indirect principle and a heating element that directly heats the water in the tank. The working element maintains the temperature at the required level, but most of the heating is provided by the coil.

Reference! Combined storage devices are suitable for single- and dual-circuit low-power equipment. Reduce electricity consumption during the heating season, providing the necessary heating of water during the entire service life.

How to connect a device for a boiler with two circuits

The boiler is selected after determining its type, location and volume relative to the power of the water heater. In indirect and combined type storage tanks, it is recommended to provide additional protection against scale inside the coil.

Attention! It is prohibited to connect the boiler before the boiler is put into operation gas service.

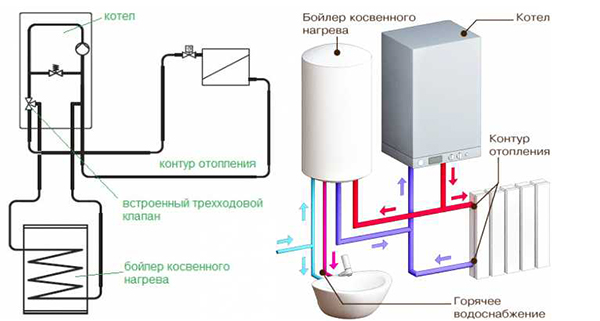

Wiring diagram

Wiring diagram depends on the type of tank:

Direct heating device

The inlet pipe of the storage tank is connected to the cold water supply inlet. The outlet pipe is to the entrance to the second circuit of the boiler.

Cold water flows directly into the boiler, where it is heated up to 60 °C under the influence of heating element.

From the boiler, the liquid is sent to the boiler, losing water along the way. a few degrees of temperature. Passing through the second heat exchanger of the heating device, the water restores losses and goes into the DHW system through the boiler outlet valve.

Indirect and combined heating

They have two additional pipes from the coils. They are connected to the first circuit of the boiler. The operating scheme assumes that the heated coolant of the heating system will first pass through the accumulator coil, and only then go to the radiators.

Due to this, the main heating gradient of tap water is provided by the coil. Cold water is entered directly into the storage device, heated liquid is diverted to the boiler's DHW circuit.

When clocking, i.e. periodically turning on and off the burner by the automation of the boiler operating with an indirect heating boiler, it is recommended to change the connection diagram of the tank. Clocking of the boiler indicates that the water in the storage tank does not heat up to the required 60 °C.

The hot water supply circuit pipes of the water heater are plugged, and the water from the boiler is immediately sent to consumers. The rate of heating of the liquid depends solely on the power heating systems, it is impossible to operate this system in the summer.

Photo 3. Connection diagram of an indirect water heating boiler for a double-circuit gas boiler.

Materials and tools

The internal elements of the boilers are made made of copper, steel or cast iron. Heating elements and coils are made of copper or steel. The steel walls of the tank are subject to corrosion, the service life does not exceed 15 years. Cast iron walls are twice as massive and expensive, but they work properly. up to 90 years.

When installing a boiler, detachable pipe connections are provided. For this you need:

- tape measure, pencil, chalk;

- hammer drill with a set of drills (for making holes for pipelines, wall mounting elements);

- adjustable wrenches and spanners (models with ratchets are recommended);

- set of screwdrivers;

- pliers;

- nippers;

- joint sealant (linen, FUM tape, plumbing thread);

- sealants;

- shut-off valves, tees;

- fitting;

- pipes.

If it is not possible to arrange detachable connections, they are used polypropylene pipes, welded on site.

Step-by-step installation and quality control

All work is carried out with the equipment turned off and the liquid removed from the system.

- Marking the fastenings with a pencil or chalk. Drilling mounting holes.

- Checking the load-bearing capacity of the wall. Relevant for wall-mounted models. The fasteners included with the storage unit are installed on the wall and loaded with bags of cement or sand at a rate of double the reserve.

If the wall material can withstand the load 100 kg, then you can hang a boiler with a volume of up to 50 l.

- Placing the container on the wall or on the floor.

- Cutting into the water supply.

- Installation of excess pressure valves along the water flow.

- Installation of expansion tank.

- Filling with water and checking the tightness of the connections. If after an hour of downtime the system filled with water does not leak, then the tightness of the connections is satisfactory.

- Connecting the equipment to the network, checking its operation.

Useful video

From the video you can find out the opinion of a specialist about how an indirect boiler with a boiler of two circuits will work.

Features of operation, prevention of malfunctions

The walls of a properly functioning boiler are at room temperature, the device does not make noise, and does not consume electricity in excess of that specified in the passport. warms up in 20-30 minutes.

Long heating indicates that scale or debris has accumulated in the tank. The problem can be solved mechanical or chemical cleaning. Both require draining the water and removing the tank.

For the first one disassembly is in progress boilers, walls and heating elements are cleaned manually. For dry cleaning no disassembly required.

The removed storage tank is turned over, a solution of citric acid or anti-scale is poured into the cold water inlet pipe, and the boiler is left in this form. for a few hours. Then the cleaning liquid is drained, the container is installed in place and washed with water.

A hot boiler body indicates a depressurization of the tank due to microcracksIt is impossible to fix the problem on your own; the device needs to be repaired or replaced.