Before buying, it is useful to know how everything works: the diagram of a double-circuit gas boiler and the operating principle

Heating a house with "blue fuel" is popular all over the worldA large number of modifications of gas boilers have been developed.

On sale are floor-standing, wall-mounted, single-circuit, double-circuit, with an open or closed combustion chamber, with a bimetallic heat exchanger or indirect heating boiler, condensing or atmospheric.

Choose the right functions and design boiler can only be accurately formulated by formulating the tasks facing the heating equipment.

One or two circuits for wall-mounted and floor-standing boilers?

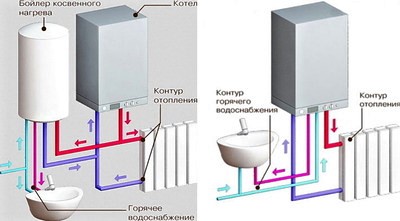

The main difference between a single-circuit boiler and a double-circuit boiler is the ability to heat running tap water.

Single-circuit consists of from three parts:

- Burners.

- Heat exchanger.

- Control and management systems.

Dual-circuit much more difficult single-circuit. It contains units responsible for heating hot water. This is an additional heat exchanger, a three-way valve, a circulation pump, a sensor system and electronic automation.

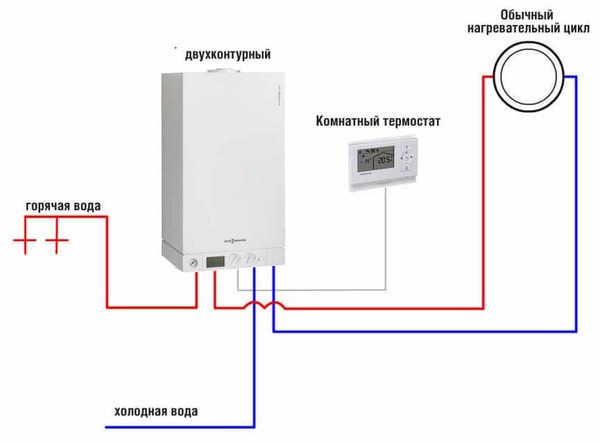

Double-circuit boiler works in two modes:

- Mode heating of the coolant heating. The burner burns gas, heating the coolant. The switching on and intensity of the flame is regulated by simple mechanical or electrical automation, the coolant is pumped by a pump.

- Mode DHW. The user opens the shower tap, for example. Water begins to circulate through the boiler, the pressure sensor turns on. The automation turns on the three-way valve. The hot coolant begins to circulate through the secondary heat exchanger, which heats the water for the shower. As soon as the user closes the tap, the circulation of the coolant through the secondary heat exchanger stops.

Photo 1. A diagram showing the operation of a dual-circuit boiler. The blue color shows the movement of cold water, the red color shows the movement of hot water.

If the house already has a heating system with a single-circuit boiler, hot water supply is provided additional boiler indirect heating. Such a scheme has both advantages, So and disadvantages. Using a double-circuit boiler is cheaper, modern boilers are technologically advanced and allow you to heat as much water as required with precision in maintaining the set temperature.

Heating equipment device

Various elements gas boilers are made from materials that meet the requirements of the tasks materials.

When choosing, it is worth paying attention to several useful details that affect the cost and durability of the device.

- Body and parts three-way valves or sensors with a moving part are made of brass, bronze or plasticThe use of corrosive metals is undesirable.

- Strapping pipes boilers are performed more often from the same material as the heat exchanger.

- Body and frame - from sheet steel.

- Single-circuit heat exchangers boilers are made of steel or cast iron, less often from aluminum or copper. For dual-circuit applies copper or stainless steelIt is best to choose boilers with copper heat exchangers, since copper is less susceptible to corrosion and has excellent heat transfer characteristics.

Important! When selecting and installing a boiler, it is advisable to ensure that no electrochemical pair was formed. If present in the system copper and aluminum elements, the latter inevitably corrode. Therefore, you should not install aluminum batteries and a copper heat exchanger.

Characteristics of a double-circuit gas boiler

When choosing a double-circuit boiler, it is worth paying attention not only to the materials, but also to the declared characteristics:

- Power. The larger the area of the heated house and the greater its heat loss, the more powerful the boiler will be required. For the house in 100 square meters in temperate latitudes you will need a boiler with a capacity of 12 kW.

- Efficiency. Improved heat exchangers and burners of double-circuit boilers, the presence of “smart” automation and control programs allow to bring the efficiency closer to fantastic 98%.

- View of combustion chamber. There are boilers with open and closed combustion chambers.

When closed In the combustion chamber, air is supplied and combustion products are emitted through a special coaxial flue. Open the combustion chamber uses the air in the room, and the exhaust goes into a stationary chimney with natural draft. For boilers with an open combustion chamber, a chimney and a separate boiler room are required. With a closed combustion chamber, they can be installed near any external wall, but they are more expensive.

- Availability additional condensation system. Temperature of exhaust gases ordinary boiler near 150 degrees, A condensation — total 40The temperature difference is used to heat the house.

Heating schemes

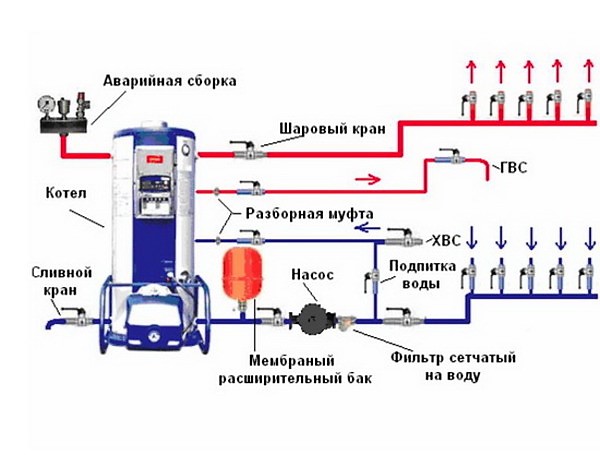

Double-circuit boilers work only with closed ones heating systems with forced water circulation.

Photo 2. Connection diagram of a double-circuit boiler to the heating system. The main elements are indicated.

Such systems consist of:

- Boiler.

- Expansion tank membrane type. It keeps the whole system under a certain pressure - 1.2—2 atmospheres.

- Security groups. It consists of valves and fittings steam discharge. When the coolant boils or the pressure is too high, excess coolant is discharged into the sewer system. It is installed at the highest point of the system and serves to bleed air when filling with coolant.

Attention! No relief valve may lead to rupture heating systems, failure of an expensive boiler.

- Pipe and battery systems to distribute heat throughout the house.

Operating principles of different types of systems

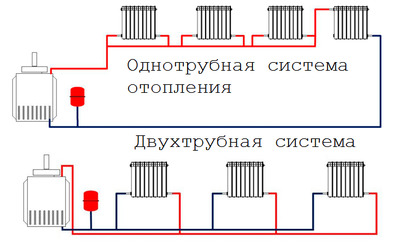

They highlight three popular types of layout:

- Single pipe. The batteries are connected to one pipe in series. One end of the pipe is the feed, the other one comes to the boiler as a return. A single-pipe system allows you to easily heat a small one-story house.

- Double pipe. The coolant heated in the boiler enters the heating batteries through the feed pipe, and cooled returns through the return pipe. Such a system is appropriate if the house consists of several floors or is logically divided into sections by rooms.

- Warm floor. This system is gaining popularity. Long thin plastic tubes are laid in uniform spirals in the thickness of the floor screed. A coolant with a low temperature circulates through the tubes, and the entire floor area gradually heats the room. Connection of different rooms occurs through a manifold-comb with thermostatic valves. If there is a need to connect warm floors and batteries, a three-way valve for mixing hot water is installed in the system.

Parameters

When planning heating for a private home, it is worth paying attention to the following characteristics of heating systems:

- Power. It is calculated taking into account the heat loss of the building and the volume of air.

- Temperature adjustment option. Gas double-circuit boilers are capable of maintaining the coolant temperature within precisely specified limits.

- Energy independence. The downside of dual-circuit boilers is their dependence on electricity. The operation of the control unit, sensors and pump requires the connection of current with certain parameters. Autonomous power supply systems can offset this downside: uninterruptible power supply units, solar panels, autonomous generators with internal combustion engines.

Useful video

Watch the video, which examines the parameters of gas boilers and explains how to make the best choice.

What to consider before choosing

When choosing, you need to determine positive and negative qualities double-circuit boilers:

- Price. It is worth calculating whether there is a need to overpay for expensive equipment, whether some additional elements are needed. A double-circuit boiler is more expensive, but will be cheaper than a combination of a single-circuit and a water heater.

- Ease of use. Cheap systems are regulated and serviced manually. If the boiler has an electronic control unit that takes into account dozens of parameters, you will need to approach the heating equipment less often. Such a system is more expensive and is not always needed. Double-circuit systems, due to their complex configuration, require proper control.

Photo 3. Double-circuit gas boiler Ariston ALTEAS X 24 FF NG with electronic control unit and touch display.

- The need to heat an unlimited amount of running water. Double-circuit boilers cope with this task brilliantly. But it is worth understanding that in most boilers both circuits cannot work simultaneously. Either heating or heating of running water functions.

- Correct regulation of the temperature of hot drinking water. Double-circuit boilers have problems with this - tap water can change temperature abruptly. Indirect heating or electric boilers cope with this task better, but the amount of water in them is limited.

Double-circuit boiler - a great compromise for heating and supply private home. This device copes wonderfully with the tasks assigned to it, and is suitable for any closed heating system.

Comments