What should you pay attention to when buying a wall-mounted gas boiler for heating a private home?

Wall-mounted gas boilers are also called mini boiler houses — they allow you to regulate heating parameters and monitor the status of the equipment.

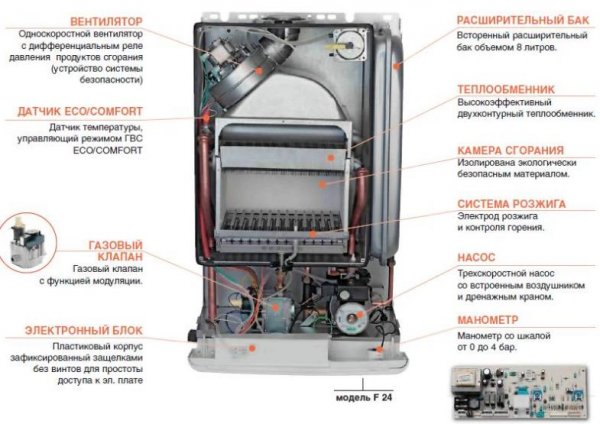

The small body contains heat exchanger, burner, control panel, as well as pumps, tank and sensors.

Boilers are used to heat private homes; it is difficult to install such a device in apartment buildings.

Content

Features of wall-mounted gas boilers for heating a two-story private house

The following types of boilers are distinguished.

By the principle of the device:

- single-circuit;

- double-circuit.

Photo 1. Wall-mounted double-circuit gas boiler model Gepard 23, manufacturer - "Protherm", Slovakia.

Representatives first category serve only a heating purpose, and second They will also heat up the water for washing.

There are also gas wall-mounted units:

- convection;

- condensation.

By combustion chamber - open and closed. With plate or bithermic heat exchanger.

Single-circuit boiler diagram

The single-circuit boiler for wall mounting is quite simple. The design includes:

- gas burner;

- circulation pump;

- heat exchanger;

- expansion tank;

- pipes.

With the help of the latter, the device is connected to the heating system and boiler, and the unit is attached to the gas main using a special valve.

Photo 2. Diagram of a single-circuit wall-mounted gas boiler with a closed combustion chamber, model F24, manufacturer - "Ferolli".

The operating principle depends on the presence of a connection to the boiler. It happens that the external heater is not connected, then the pump pumps water into the heating system until it heats up to the required level, after which the device goes into standby mode. If an external boiler is connected, then as soon as the water in it heats up to the required temperature, the fuel combustion stops.

Key technical characteristics

Wall-mounted boilers are much more advantageous than floor-mounted boilers for a number of reasons. The main thing is that all control devices and units are located in one building, the boiler does not require additional equipment.

The wall-mounted version is much more compact and fits into any interior more easily than floor. The parameters of the boilers are equivalent in characteristics:

- power indicator;

- type of fuel;

- efficiency;

- temperature "fork";

- tank volume;

- fuel consumption;

- gas pressure indicator;

- level of electricity consumed;

- dimensions;

- size of the heated room;

- flue diameter.

These are the main parameters. And depending on the type of boiler, other indicators are often included here.

Requirements for installation and wooden premises

Installing a gas boiler, no matter where it is located, on the floor or on the wall, is a redevelopment, the inclusion of an element not previously envisaged by the project. Therefore, before starting work, get permission from Gorgaz. At the slightest discrepancy with SNiP installation will be denied.

Then the designers develop a model, which necessarily describes connection point, provide a detailed diagram of gas supply to a specific area (if a private house is meant).

No matter what kind of room we are talking about, you will have to take into account a number of requirements, without which it will not be possible to hang the boiler on the wall:

- room area - not less than four m2;

- doorway - not narrower than 0.8 m;

- good lighting boiler room;

- the ceiling is quite high (minimum 2.5 m);

- present ground loop;

- smooth walls, covered with a special fire-resistant composition;

- availability cold water supply.

Attention! Any room after installation of the boiler potentially explosive. A wooden house requires a separate extension with direct access to the street.

Installation of a heating device

The work includes several stages:

- wall mount (the distance between the wall and the device cannot be less than three to five centimeters!) on brackets;

- examination traction in the outlet pipe;

- examination diameter (the flue and inlet opening are the same size);

- testing tightness connections;

- connection to water supply;

- connection water softening devices;

- connection to gas source (a flexible hose and paronite gaskets are used).

After this, the tightness is carefully checked again.

Tools and materials

To install the device on the wall, you will first need: fastening devices (hooks, power dowels). They usually come with the boiler. If there are no fasteners, you will have to buy them yourself.

To hang a gas heater on the wall you will need:

- electric drill;

- hammer drill;

- set of metal pipes;

- construction laser level.

The latter is used to check whether the boiler hangs level. Deviations from the vertical are unacceptable. If this is neglected, even an expensive device will break soon after connection.

Job Description

Typically, the installation is done in the kitchen. Before you begin, make sure it is well ventilated and has an outlet with a through hole in the door.

Otherwise Gorgaz and fire service they simply will not legitimize such an innovation, even if the supervisory authorities are presented with a fait accompli.

The result will be an order to eliminate the innovation or a fine, or even more serious trouble.

When installing a gas boiler, rely on SNiP 42-01-2002. And also the norms SNiP 2.04.08-87 - this source as of 2018 has lost its validity, but contains a lot of useful data from a technical perspective.

Inspect the surface where you are going to attach the heater. Not all walls, especially plasterboard ones, will support a hanging boiler with reinforced fastening. If in doubt, it is better to reinforce the wall wooden boards. It should also be taken into account that the wall covering itself must be fire-resistant. If necessary, the surface is covered sheet made of non-flammable material.

When hanging, keep the distance. The heater should not be placed close to the wall. less than 45 cm. About to the floor up to 1.5 meters, but not less than 80 cm. The remaining walls can be covered with ceramic tiles.

Important! When hanging a condensing gas heater, remember that upper part the boiler is closer to the wall than the bottom one.

Features of operation

A gas boiler, wherever it is located, is a complex and dangerous device, the operation of which requires constant control.

The latter will be provided either by a person constantly on duty in the boiler room, which is almost always physically impossible, or automatic control system.

It provides multi-level protection against danger in case of failures. The main action is automatic shutdown of the device in case of failure and elimination of its causes.

Recommendations for selection

Which device is better to buy depends on the parameters of the home and the financial capabilities of the person. Single-circuit the boiler is cheaper. It is the one that is bought if the task is only to heat the room, and not to solve the problem of constant availability of hot water.

You can connect a boiler to it, which is responsible for indirect heating, but this will require much more space. For smaller houses, it is better to dual-circuit. And also choose it if it is important to save electricity.

The dual-circuit device turns on when the power goes out. hot water, and a single-circuit one - as soon as it cools down. It turns out that a cheap option with one circuit does not save money at all if its purchase does not solve all existing heating problems.

Photo 3. Wall-mounted double-circuit gas boiler model Logamax UO72 with a closed chamber, manufacturer - "Buderus".

It should also be taken into account ignition type. It is better to choose models with electric ignition, it is simple and economical.

Plays a role and burner. A gas unit with a closed burner is suitable for any home, including an apartment building.

For added security, choose a device with flame regulation capability (This is especially important for flow-through heaters). It is necessary for the boiler to have temperature sensors outside and inside the room.

When choosing a manufacturer, you should trust those that have a good reputation, provide a long warranty and have access to specialized service centers.

Pros and cons

Advantages:

- high efficiency;

- possibility to heat large room;

- cheap fuel;

- high energy output at low consumption;

- Continuous fuel supply: human presence and supervision of the continuity of the process is not required;

- ease of use;

- durability.

Flaws:

- set special conditions (not all of them can be observed);

- agreement with gas service Necessarily;

- high demands on ventilation premises (otherwise soot will appear and efficiency will decrease);

- gas boiler is not suitable for indoor use less than 100 m2 due to the risk of leakage.

Reference! Any unit, including a wall-mounted one, must have automatic control system, only then can we talk about the absence of risks.

Useful video

Watch the video to learn about the rules for choosing a gas boiler.

If the gas boiler is faulty

Signs that something is wrong with a gas heater include:

- the fire soon goes out;

- the boiler does not start;

- loud noise;

- rapid wear of parts;

- leak in heat exchanger;

- the gas burns, but there are popping sounds;

- the appearance of fistulas;

- rapid decrease in water temperature;

- blown out.

All that can be done here is to call quickly specialist. The only thing that a layman can do without risk to himself is to take up chimney.

The sensors the boiler is equipped with show the concentration level of waste products. If the pipe is clogged, there is no draft, you can clean the flue, fix the problem or even replace it. As soon as the sensor detects the required ventilation level, the operation will return to normal.

Attention! Opening the boiler is extremely dangerous! You can trust repair work on a gas boiler only to a qualified technician with a special level of clearance.

The fact that a working boiler suddenly starts to turn off, the burner weakens and goes out, may indicate the filter is clogged or the automatic system is about to failWhether this is true can only be confirmed by a specialist with diagnostic equipment.