Examples of popular connection diagrams for a single-circuit gas boiler with an indirect heating boiler

For the installation of a hot water supply system (HWS) there is several options, some of them are double-circuit and single-circuit boilers with a separate boiler.

If in a dual-circuit device a small heat exchanger that heats water for hot water supply is already built in, then in a single-circuit system with a boiler, the task of heating water for domestic needs is assigned to it.

Double-circuit boilers are usually equipped with relatively small capacity for hot water supply, therefore they cannot provide the required temperature for many consumers over a long period of time.

Content

Types of gas boilers with indirect heating boilers

Eat two options water heaters for hot water supply:

- indirect heating (IH);

- direct heating.

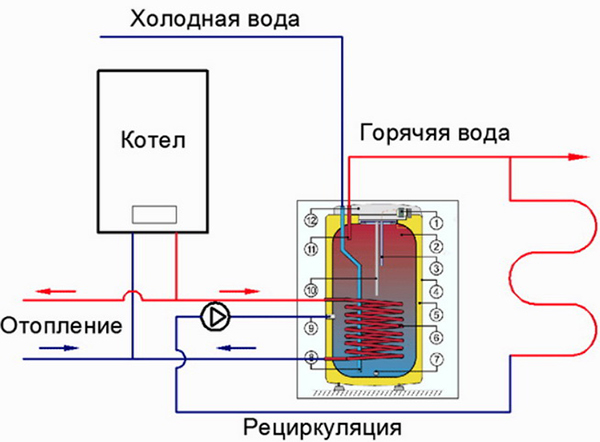

The BKN is connected to the installed gas boiler. Inside it is a heat exchanger (this can be a pipe twisted in a spiral or a "tank in a tank" scheme).

Hot water from the heating system circulates through this heat exchanger, heating the water in the boiler. The latter is connected to the cold water supply network (CWS), and hot water from the detachable pipe is supplied to consumers.

Direct heating boiler can be compared with a conventional gas boiler heating. It also has a gas burner and a water tank. The burner heats the water in the tank independently of the central heating system.

Important! When installing a BKN, it is necessary to estimate the power that will be spent on hot water supply. If there are many consumers and water is used frequently, the boiler capacity may not be sufficient for heating, and the temperature in the rooms will be lower than set.

In this case, it is advisable to replace the boiler with a more powerful one, or use a different type of water heater.

Schemes for connecting a boiler to a single-circuit boiler

Exists three ways connecting the boiler to the boiler.

Direct connection of the water heater to the heating system

In this version, the BKN is included in the heating system, in series or parallel with other radiators. The simplest and most ineffective scheme, not recommended for use and given for reference.

Photo 1. Diagram of direct connection of a single-circuit gas water heating boiler to the heating system.

If the boiler temperature is set below 60 °C, this scheme becomes even less economical, and the water takes a very long time to heat up.

Temperature increase

The following is added to the connection diagram three-way valve — a special device that switches the movement of the coolant when the temperature in the water heater tank drops to DHW and vice versa.

Thus, if the hot water cools down, The heating is temporarily turned off.

All boiler power is redirected to hot water supply.

The temperature on the device in this circuit is set higher (usually 80–90 °C).

And the heating temperature is regulated by a three-way valve.

Reference! The boiler temperature must be set by 5 °C above the required water in the hot water supply.

Using a thermostat in a water heater and automation

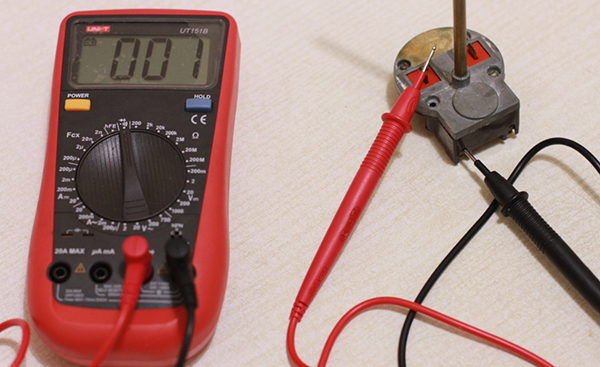

If the BKN has a thermal relay (a device that sends a signal when a set temperature is reached), and the boiler controller has contacts for connection boiler thermostat, then this scheme is the most preferable.

In this case, the boiler electronics know about the temperature of the water in the DHW system, and it decides for itself, where to direct its power: for heating water in the boiler or for heating.

Photo 2. Thermostat for a water heater in a heating system, with it you can find out data on the water temperature.

Materials and tools

Materials:

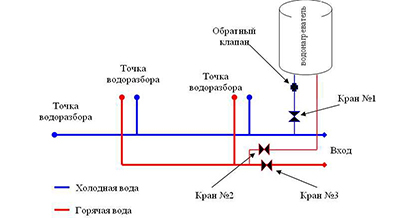

- Pipes, shut-off valves, check valves — there are no special requirements for them: use the same materials as for working with hot water supply or heating systems.

- Expansion tank — a separate one is required for the domestic water supply system, it serves to prevent sudden pressure drops when opening/closing taps.

Attention! The tank must be designed for use with hot water, usually such devices are marked special marking.

- Circulation pump — as a rule, a separate pump is installed in the heat exchange circuit with the water heater.

In addition, in DHW systems with recirculation, a separate pump is required to circulate water in the DHW circuit.

This will eliminate the need to wait for hot water to arrive through long pipes from the location where the water heater is installed: the water will be hot immediately.

- Wires and small electrical wiring — if you plan to connect the water heater thermostat to the boiler automation.

- Fasteners - especially in case of wall mounting, also for fixing pipes and pumps.

- Standard plumbing set of sealants, gaskets and gaskets.

Tool:

- gas wrench;

- spanners of various diameters;

- adjustable wrench;

- building level;

- hammer drill, screwdrivers, power screwdriver;

- Minimum set of electrician's equipment: knife, nippers, electrical tape, phase tester.

Installation process: how to connect

Ideally, the boiler should be located as far away as possible. closer to the heating boiler to minimize heat loss.

Cold water is always supplied to the lower pipe of the boiler, and hot water is taken from the upper one.

- Select a location for the water heater so that it doesn't interfere and is easy to maintain. Mount brackets, stands, and secure it to them.

- Connect to the cold water supply network: make a branch, install a shut-off valve and a coarse filter.

- Through the tee, take the cold water supply line to the consumers., connect the second output to the boiler through a safety valve.

- Connect the DHW line in the house to the boiler, not forgetting about the expansion tank on it. In addition, install bypass valves so that you can disconnect it from the circuit during maintenance.

- Now connect the boiler to the gas boiler using one of the diagrams provided. Don't forget to turn off the boiler and shut off the system before connecting!

- Connect electronics, sensors, pumps according to the instructions.

Launch and check

After installation, first of all, it is necessary to connect and fill the boiler with cold water. Make sure that all air locks are removed from the system and the boiler is completely filled, to avoid causing it to overheat.

When the boiler is full, set the desired temperature using the automatic control. Start the boiler, open the coolant supply from the heating system to the boiler.

Once the system is in working order, make sure that the relief valve (usually set at 8 bar) does not leak, i.e. there is no excess pressure in the system. And you should also check all connections, seals and taps for leaks.

Useful video

The video provides instructions on how to properly connect a boiler to a gas boiler.

Regular maintenance is the key to long-lasting hot water supply

The installed boiler requires periodic maintenance. By following these simple steps, you will ensure that many years of reliable and uninterrupted water supply:

- Do not overheat the water heater. Operating at very high temperatures may cause premature damage to the interior of the tank.

- Control your pressure. Inspect the safety valves once a month and also make sure that the pressure in the water supply system is not lower or higher than the values recommended in the instructions.

- Replace the magnesium anode regularly. This device "attracts" metal ions dissolved in water. If the anode is destroyed, the aggressive environment can lead to corrosion of the boiler walls and its failure. Depending on the manufacturer's recommendations, the magnesium anode is changed every six months, or once every 2–10 years.