Efficiency increased several times! Pyrolysis boiler: what is it, principles of its operation

You are viewing the section Pyrolysis, located in the large section Boilers.

The operation of a pyrolysis boiler is based on a special chemical reaction - pyrolysis.

This term refers to the process of decomposition of organic fuels. for gas and coal. At the same time, thermal energy is released in large volumes.

The process is possible only under certain conditions: lack of oxygen in the space. High temperature: 200–800 °C.

Principles of pyrolysis for heating

Pyrolysis is widely used in various industries. This chemical process is in demand and for heating living spaces.

Pyrolysis occurs with any type of solid raw material:

- Firewood.

- Small branches or wood shavings.

- Briquettes.

- Peat.

- Brown coal.

- Pellets.

- Coke.

However, the pyrolysis unit operates most efficiently on fuel with a higher level of volatile matter output – wood. thickness 80-100 mm. Pellets or wood waste are used together with them.

Attention! It is not advisable to use only sawdust or pellets - with them the boiler does not generate heat or it Efficiency is reduced to a minimum.

Pyrolysis boiler: what does it mean, its device

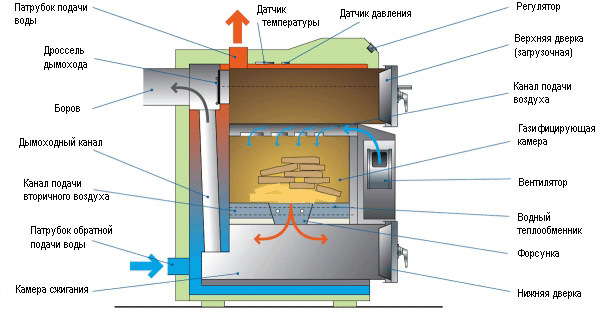

Design pyrolysis boiler looks like this:

- Chimney.

- Control unit.

- Loading hopper.

- Nozzle.

- Combustion chamber.

- Heat exchanger.

The pyrolysis heating boiler is a two-chamber unit - this is its special feature. The main chemical reaction in these chambers is:

- Loading chamber or gasification chamber. Here, the preliminary thermal decomposition of the raw material occurs. The organic matter under the influence of high temperatures turns into combustible gas. Primary air is directed into the chamber to maintain smoldering. Combustion at a temperature of 300—800 °C.

Photo 1. Fuel loading chamber in a pyrolysis boiler. The interior is finished with fireclay bricks.

- Combustion chamber. After smoldering, the released air and gas get here. Here, the resulting gas burns like ordinary natural gas. Temperature on average 1200 °C. It is at this stage that a lot of heat is released, which is necessary for heating. At the same time, there is a strong aerodynamic resistance, so forced draft is necessary, the role of which is performed by a smoke exhauster.

Two spaces between the chambers divides the grate, into which the fuel is loaded. There it is ignited and the smoke exhauster is started. The grate prevents heat from escaping from the upper loading chamber and provides a light flow of primary air.

Pyrolysis furnaces equipped with traction switches, which ignite the fuel. Thus, at the beginning of ignition, the boiler functions as a direct combustion device, and after closing the valve, it switches to pyrolysis.

Types of pyrolysis devices, characteristics

Pyrolysis boilers differ in their design. So, there are:

- Afterburner chamber on top. Rarely encountered. The advantages of the design are that the flue gas passes unhindered into the afterburning chamber, and after burning out, it immediately enters the chimney for further cooling. Among the disadvantages is the location of the smoke system is uneconomical, since more consumables are initially required to manufacture such a design.

Photo 2. Pyrolysis boiler with a lower afterburning chamber. The arrows indicate the components of the device.

- Afterburner chamber at the bottom. The most common and most comfortable type of design. It is convenient for the user to load firewood, since the chamber is not on the floor. The chamber also has a direct outlet to the lower flue, and from there to the chimney. However, such a design also has its drawbacks. Thus, ash from the loading compartment clogs the second chamber, so it is cleaned more often. In addition, it is necessary to provide increased draft so that the smoke moves downwards.

And also pyrolysis boilers differ in the type of traction used:

- Natural draft. No need for electricity. However, for operation it requires a fairly high chimney with a powerful natural draft, which will be expensive.

- Forced boost and traction. The boiler becomes energy-dependent, however, the speed of entering the mode increases. Such a unit is equipped with fans and smoke exhausters, which are controlled by automation - the dependence on weather conditions completely disappears and combustion efficiency increases. This type of furnace can operate with the maximum efficiency level throughout 4-5 hours, and this 20% more, than a natural draft boiler.

There are two types according to the heating method. pyrolysis devices:

- For water heating. The heat carrier is water, which is heated in the heat exchanger, then poured through pipes into the radiators. The temperature is maintained due to constant circulation.

- For air heating. It is used much less frequently in domestic conditions. It is often used to heat outbuildings or production facilities. Thermal energy is distributed in the room using warm air masses. They are heated as a result of combustion of raw materials. Heat is distributed by means of aluminum pipes and blowersThis system is controlled automatically, so the owner can easily customize it according to his needs.

How to choose such a device

When choosing a pyrolysis-based unit pay attention to its key characteristics:

Quality of the case. Previously, the firebox body was made mainly of cast iron.

Now manufacturers produce a welded body made of sheet material.

The main thing here is its thickness.

It depends on the boiler power:

- 15—65 kW: internal structures 5 mm, external - 4 mm;

- 75-110 kW: internal - 6 mm, external — 5 mm;

- 135-195 kW: inside - 8 mm, outside - 6 mm;

- 200 kW and more: internal components - 10 mm, external - 8 mm.

Power. This indicator depends on the heated area. There are many methods for determining the power. The simplest and most optimal among them is to take as a basis 1 kW per 10 square meters heated area.

Experts recommend the unit with 10% power reserve. So, for placing on 120 square meters a boiler will do 16 kW. If the area of the territory 160 square meters, the power of the device must be at least 18 kW, and so on according to the same principle.

Reference. If the height of the ceilings in the heated room exceeds 3 m, for each additional meter the boiler power is added by 1-3%.

Energy efficiency. Indicates the ratio of useful heat that was spent to the volume of raw materials used. This indicator depends mainly on the fuel. Thus, for effective heating, only dry consumables are needed.

However, the volume of the loading chamber, which holds the firewood, is also taken into account. up to 60-65 cm. Besides this, both cameras coated with a special a layer of ceramic concrete - it maintains a suitable temperature inside. As a result, the fuel burns more efficiently and effectively.

Important! A boiler that provides is considered optimal at least 10 continuous hours of burning raw materials and serves without interruption for a long time 20 years old.

Price. Pyrolysis boilers are more expensive than other types of heating boilers. However, there are options here too. Thus, domestic 2-3 times cheaper imported, and their characteristics are not inferior to foreign analogues.

Benefits of using

- Burning duration.

After one bookmark, such a device works smoothly. up to 12 o'clock, that is, it has to be loaded further 2 times less often, than other solid fuel boilers.

However, it all depends on the type: a regular wood-burning fireplace works for about 4 hours, and with top combustion - on average 30 hours on firewood and 5-7 days on coal.

This effect is achieved due to the controlled combustion process. Many modern models have automatic control of operation. The duration of combustion also depends on the volume of living space, the air temperature in the room and outside, the design of the unit and its power.

- Efficiency 85-90%.

- Complete combustion of raw materials.

Less consumption of raw materials, The flues and ash pan need to be cleaned less often.

- Environmentally friendly.

As a result of the smoldering of wood or similar types of fuel, 3 times less harmful substances, than in other solid fuel boilers. In addition, harmful emissions into the atmosphere are minimized under the influence of hot temperatures in the upper chamber.

- Cost-effectiveness.

Even large unsplit firewood is suitable for combustion. In addition, two-chamber combustion reduces excess air in the exhaust gas, which also increases savings. Compared to other types of solid fuel boilers, the efficiency of pyrolysis units is higher by 5-8%.

Cons

- Energy dependence. Most often, such boilers cannot operate without a smoke exhauster. A system with a generator is required for forced draft. The fan uses electricity in the amount of at least 80-100 W.

- High price. On average 1.5-2 times more expensive other types.

- Fuel moisture sensitivity. Maximum dryness is necessary. Thus, when burning 1 kg firewood with 20% humidity, the operating power of the equipment will be 4 kW. If you take 1 kg firewood with 50% humidity, the power decreases 2 times and achieves everything 2 kW.

- Unstable operation of the unit at low loads (below 50%), tar build-up in the flue gas duct.

- Large dimensions pyrolysis equipment.

- Pyrolysis boilers are exclusively single-circuitTo heat water for domestic use, a separate unit will be required.

- It is not possible to automate the fuel loading process — loaded exclusively manually.

Safe to use

Functioning of the pyrolysis boiler implies operation at the highest possible temperatures. Therefore, each manufacturer places high demands on the installation and operation of equipment.

The installation is carried out by a specialist with the necessary competence. The boiler is placed in a separate room with good ventilation, and a chimney is installed on the unit.

Also taken into account the following operating rules:

- If there is no sufficient draft or the required coolant, the boiler cannot be used.

- Loading and lighting of the equipment must not be entrusted to children or any other unauthorized persons.

- The temperature of the water in the system of pipes going through the boiler, should not exceed 95 °C. If the indicator is exceeded, the flame in the unit chamber is weakened for a while using sand. In parallel with this, all possible flue dampers are opened.

- The boiler becomes very hot during operation, so there should be no flammable materials or objects near it.

- Modifying the boiler design or using it for other purposes is strictly prohibited.

Photos of pyrolysis boilers

Photo 3. Pyrolysis boiler installed at home. Firewood for kindling is stored next to it.

Photo 4. Pyrolysis boiler from the manufacturer Viessmann. The device is equipped with electronic control.

Photo 5. Pyrolysis boiler with bottom fuel loading of fairly large dimensions.

Useful video

Watch the video, which demonstrates the operation of the pyrolysis boiler, and tells how to fire it.

Conclusions

Pyrolysis boiler - a good alternative to direct combustion units. However, some experts recommend purchasing pyrolysis equipment as a backup heat source in a set with an electric or gas boiler. If you still install pyrolysis as the main heat generator, you will need competent design and highly qualified specialists for installation.