Affordable and inexpensive heating of premises: features of a pyrolysis boiler of long burning

Pyrolysis - decomposition of material at high temperature and limited oxygen supply.

In the case of a long-burning pyrolysis boiler, maximum combustion of solid fuel and gas released from it occurs.

For example, in a conventional oven, pyrolysis is not provided, so heat is released there mainly due to the combustion of wood. And pyrolysis boilers are designed so that allow additional gas combustion, which is released during fuel combustion.

As a result, one load of fuel burns longer and less firewood is required.

Content

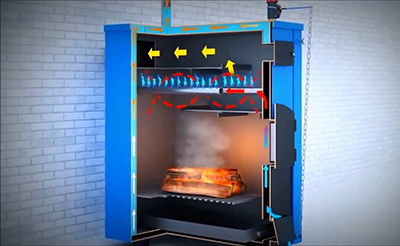

Operating principle

The main feature of pyrolysis boilers is the presence of a second chamber for afterburning the gas released during combustion. This increases the work one load of firewood up to 12 hours, and the efficiency is up to 90%.

The diagrams of such boilers include the following set of elements:

- ash pit;

- chamber for loading fuel and gasification;

- heat exchanger;

- combustion chamber;

- afterburning chamber;

- chimney.

Since the boiler's task is to heat not only the adjacent territory, but also other areas of the building, the heating system is connected to it. Therefore, the design provides inlet and outlet for water circuit. Operation begins with loading solid fuel and igniting it.

The released heat goes to the combustion chamber, and the gases released during combustion are burned in the corresponding chamber. The resulting heat goes to the heat exchanger, from which it is transferred to the heating system. Often, such units require forced draft, so a booster is installed for supercharging. fan.

Attention! The device requires maintenance, experts recommend taking breaks if the system is running longer than a day.

Natural draft pyrolysis boiler

The natural draft device can operate due to chimney pipes. In this case, hot air rises upwards, and cold air comes in from below. This option, if designed well, can cope with its task even in houses without electricity.

Photo 1. Atmos pyrolysis boiler, operating on natural draft, with a small compartment for firewood.

But the specificity of pyrolysis, in which the release of additional heat occurs due to afterburning gases, involves the use of a design with a complex air duct.

As a result, natural draft encounters more obstacles than, for example, a conventional stove. Therefore, it works less efficiently than the forced draft option. In addition, the space for firewood in such a design is smaller, and they have to be loaded more often.

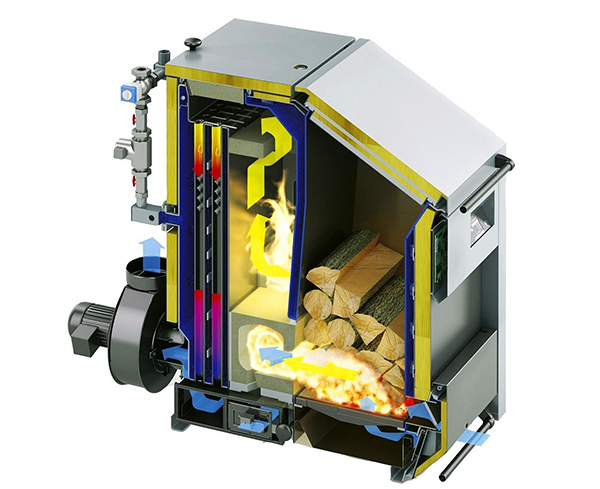

Advantages of forced draft

Forced draft provides a regular air flow. Its intensive supply allows you to overcome boiler tract and chimney in the mode necessary to maintain the process.

Photo 2. A pyrolysis boiler that operates on forced draft, providing a constant flow of air.

Although the fan requires electricity to operate, it pays for itself in a number of ways Pros:

- longer burning time;

- lower fuel consumption;

- more space between bookmarks;

- less waste and emissions into the atmosphere.

Reference! The most efficient version of a long-burning pyrolysis boiler is a design with forced draft. Efficiency reaches up to 90% thanks to the maximum fuel combustion.

What do you need to make the device yourself?

To make the device yourself, you need to choose a project that suits specific conditions and the operating principle. Of course, you can go and buy a device in a store, but make it yourself with your own hands cheaper and more efficient.

Before you start making it, you need to estimate the required power. To do this, you need to take into account area of the premises, which is to be heated.

Then it is necessary to determine whether additional automation will be installed on the boiler or not.

Automatic block allows you to monitor the room temperature and, depending on this, regulate the operation of the boiler, as well as turn off its functions in case of danger. But you can do without it too.

Having assessed the required effect from the boiler and having chosen a project, they begin to manufacture the unit. The most common project for self-assembly is considered to be Belyaev's scheme.

To implement it, appropriate measures are needed. materials and tools. Of great importance for materials is their resistance to high temperatures. In order not to make a mistake in choosing, you can contact a consultant at a metal warehouse or in a store.

Necessary tools

Typically, the materials required to make a boiler include:

- metal and profile pipes of different diameters;

- fireclay brick;

- metal sheets;

- air pump or fan;

- temperature sensor;

- heat-resistant fittings.

The list of tools required for work on the unit, includes:

- inverter and electrodes;

- grinder with circles;

- drill and metal drill bits;

- jigsaw.

Other tools may be added to these tools during the assembly process. The main thing is that they allow you to cut and connect the boiler parts, to achieve its strength and tightness, and also mount the required elements on the body.

Stages of construction of a long-burning pyrolysis boiler

Once a suitable drawing has been selected, a working version is created based on it.

The dimensions of the compartments, combustion chambers and other elements of the unit are established in accordance with the calculations carried out.

For example, the volume of the loading chamber is calculated according to the principle 2 liters per kilogram of fuel, which is planned to be used, plus 30%.

This is because the firewood may have uneven edges and will not fit flush against each other, increasing the area taken up.

The dimensions are also worth estimating. based on a power of 20-25 kW. You can still find materials for it when assembling it manually. With greater power, you need thicker steel, which is extremely difficult to weld at home due to the need for powerful equipment.

The list of actions for making a pyrolysis boiler includes:

- Cutting pipes and sheets with a grinder.

- Drilling holes.

- Welding of the firebox.

- Installation of partition for smoke circulation.

- Installing the grate between the combustion chamber and the afterburning section.

- Connecting the pipe with a valve at the top.

- Making holes from metal scraps for combustion chambers and ash chambers.

- Installation of vertical steel lintels between the inner and outer sides of the heat exchanger.

- Installation of water supply connections.

- Installation of doors of the unit with asbestos layer for thermal insulation.

- Laying fireclay bricks in the afterburning zone.

- Installation of adjustable legs for boiler balancing.

- Grinding the surface of the unit.

- Coated with heat-resistant paint.

- Installation of a smoke exhauster or air pump.

- Installation of a temperature sensor or automation.

The number of operations may be reduced or increased depending on the requirements.

Connection to the heating system

The pyrolysis boiler of long burning can be connected to natural and forced heating systems. In the first case, it is necessary to carefully check the slope of the pipes. In the second - determine the pump power to pump water flow.

Important! Adjust the mixing of hot water from the outlet to the inlet so that the temperature of the liquid does not drop when it enters the heat exchanger. below 60 °C. Otherwise, there is a risk corrosion of the device.

The procedure for connecting the boiler to the heating system includes:

- Filling the system with coolant.

- Connecting the pump to the network for air.

- Loading fuel into the chamber and ignition.

- Air supply regulation to the afterburning section.

Depending on the volume of supplied air, the intensity of gas combustion and the heating temperature of the coolant change.

Therefore, it is necessary to adjust the operation of the boiler so that so that the fuel burns completely.

Difficulties

Tightness — one of the main difficulties that arises when building a pyrolysis boiler with your own hands. Therefore, it check twice.

The first time this happens is when everyone the main boiler units are welded, but its interior is still open. The openings for the coolant are tightly blocked with plugs and water is collected in the boiler. At the place where the leak is detected, a mark is madeThen this part is digested again.

The boiler is checked for the second time when the entire system is fully assembledFor this purpose, along with water, a pressure tester is used, which pressurizes pressure of 3-4 bar, which should not drop sharply. If it remains at a stable level, the unit is sealed.

Useful video

In the video you can see how a homemade pyrolysis boiler works after connection.

How to make equipment work as efficiently as possible?

The efficiency of a long-burning pyrolysis boiler directly depends on the rules of use.

Malfunctions of the unit can be determined by the smoke coming from the pipe. gray smoke with a strong odor.

This may be a sign that the fuel is not burning completely. To solve this problem, you need to adjust the air supply. using a pump (blowing fan) or smoke exhauster.

For more detailed monitoring, the device is additionally equipped with automatic groupIt allows you to adjust the operation of the device in a timely manner and ensures safety during its operation.

To fully guarantee the efficient operation of a long-burning pyrolysis boiler, it is necessary to periodically carry it out maintenance, including diagnostics, cleaning, and replacement of units and components of the unit.