Good heating source: pyrolysis boiler drawing and operating principle

Pyrolysis is a method of decomposing organic and inorganic compounds using thermal action. Simply put, Molecules break down into simpler parts when heated.

A pyrolysis boiler is a device from the type of solid fuel boilers (most often for heating water) using heating up to 200–800 °C.

The special feature is the separate combustion of the fuel itself and the afterburning of accompanying gases and combustion products in a separate chamber of the boiler.

Operating principle: operation of a pyrolysis boiler

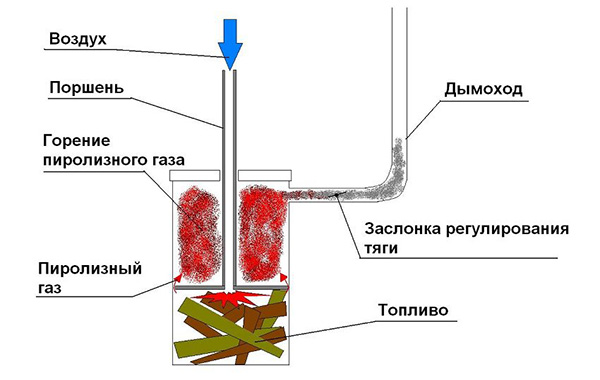

The general principle of operation of the boiler is in high-temperature heating of organic fuel with a lack of air, resulting in the formation of flammable gases.

They enter the secondary combustion chamber and there, mixing with oxygen, the gas is oxidized, releasing an additional portion of heat.

Classification

The boilers have differences by the location of the gas afterburning chambers:

- with top location;

- with a lower location.

Boilers with an upper chamber are more bulky, more material is required to assemble the flue. But they will have to be cleaned much less often, because particles from burnt fuel don't get into the camera for afterburning gases.

In boilers with a lower section, the fuel is located in the upper part, and the gases are discharged to the lower part, where they burn out. This is convenient, but you will have to frequently remove small wood particles from the gas utilization chamber.

By energy dependence Boilers are:

- without using electricity: boilers with natural draft;

- with forced draft.

Energy independent boilers imply the inclusion of a high chimney in the design (not less than 5-6 meters) to increase thrust and ensure sufficient vacuum in the combustion compartment.

The heating efficiency of such boilers will be somewhat lower than that of boilers with forced draft.

Devices with forced air flow are equipped one or two fans, which can operate in the air injection mode or in the exhaust gas extraction mode.

Some boiler models use combined method with the participation of gas injection and suction devices to increase power.

Reference! Mechanisms that pump out exhaust gases are manufactured made of special heat-resistant materials (austenitic) alloys, their cost is significantly higher than that of blower fans.

By heating method:

- Water heating - water pipelines are connected to the boiler heat exchanger, through which the heated working fluid is distributed to various rooms.

- Air heating - instead of water, air is used, receiving heat through the same heat exchanger and distributed through air ducts. The efficiency is lower than that of the water method, it is used in production areas, warehouses.

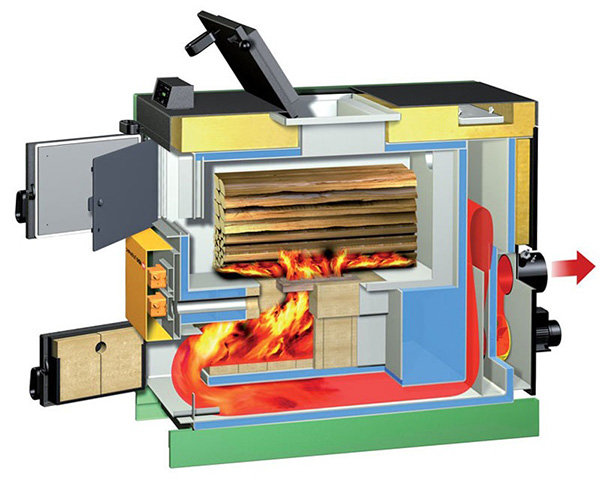

Photo 1. Pyrolysis boiler with heat exchanger, designed for water heating, runs on wood.

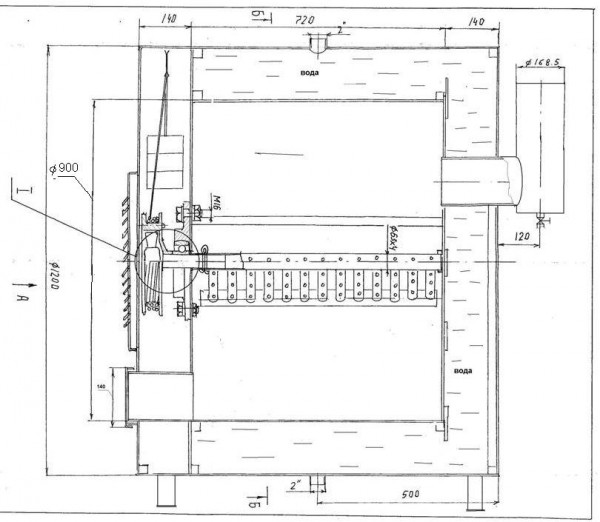

Drawing: general view, work process

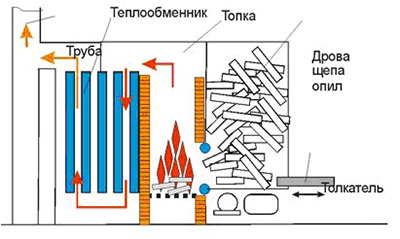

There are many design options for a pyrolysis boiler. The simplest type according to the drawing is arranged as follows.

- Combustion chamber boiler.

- Gasification compartment.

- Gas afterburning section.

- Grate bars.

- Heat exchanger (inlet/outlet pipes).

- Gas exhaust pipeline (chimney).

- Blowing holes.

- Door to the fuel loading compartment.

The boiler may include temperature sensors and devices for monitoring and maintaining normal operating modes.

And also hardware boiler for automating the functioning of the entire heating complex.

The essence of what happens inside the pyrolysis boiler is characterized by the following processes:

- An air flow from outside enters the gasification compartment with the fuel located there.

- Some oxygen will support the combustion process. (smoldering). The gases, which are products of combustion, enter the combustion chamber of the boiler through the nozzle and are oxidized there in the presence of secondary oxygen, which enters with the air from outside.

- Part of the pyrolysis gases is reduced in the presence of carbon from fuel to carbon monoxide and nitrogen oxide, consuming some of the energy in the process. The mixture passes to the afterburning section gases and oxidizes there, returning the energy it took away.

Photo 2. Drawing of a long-burning pyrolysis boiler; a device assembled according to it can heat a large house.

- The gas mixtures participating in the pyrolysis reaction are discharged to the outside through the chimney., bypassing the boiler heat exchanger.

Attention! Since the operation of pyrolysis boilers is associated with a large amount of energy generated inside the equipment and the possible release of various types of harmful gases, it is recommended to carry out independent construction of boilers only with a full understanding of all physical and chemical processes, arising during its operation.

Temperature phases:

- drying, pyrolysis of wood — 450 °C;

- combustion of wood gas and secondary air - 560 °C;

- blowing the flame and returning the heat - 1200 °C;

- removal of remaining combustion products - 160 °C.

Differences between the device and conventional boilers

Including wood (firewood), special fuel briquettes (pellets) and waste generated in production. One of the main differences between boilers is use of different types of solid fuel, virtually any substance that can burn.

The duration of the fuel combustion process is much longer than that of conventional boilers. From 8-10 hours and up. There are boiler models with a large compartment for firewood, the duration of continuous operation is up to 24 hours. This means that the combustion chamber is replenished with new portions of fuel. 1-2 times a day.

Important! Due to the fact that almost complete decomposition of solid materials occurs, pyrotechnic boilers less harmful to the environment.

Selection and calculation when purchasing: diagram

To select a boiler that is optimally suited for a particular house or complex of premises, the following considerations are used:

- Number of floors in the building. The more of them there are, the more difficult it will be to move the working substance (liquid or gas) through the pipelines.

- Defining the type of equipment, boilers of different designs operate with different efficiency. Before purchasing, you should read the documentation to determine what area the product is designed to heat.

Photo 3. Scheme of the operating principle of a pyrolysis boiler for a country house equipped with a chimney.

- Circulation pump power parameters, the possibility of its modernization or replacement to improve its performance properties.

- Chimney type and its ability to freely pass exhaust gases from the boiler into the atmosphere. Safe design implies fast removal of the gas mixture in 100% volume.

- Determining the total area heated premises. An error is allowed here: 2–3 sq. m.

- Degree of thermal insulation of premises. A carefully insulated brick house will lose heat more slowly than a metal garage or a “cold” warehouse, which means less energy will be required to maintain a comfortable air temperature.

- The region in which the premises are located. For southern territories, a simple pyrolysis boiler will do, for northern territories - a more powerful one, preferably with a reserve.

Useful video

The video tells how you can make a pyrolysis boiler for heating a room yourself.

Advantages and disadvantages

Pros:

- Efficiency 85–90%.

- Pyrolysis makes it possible to squeeze out maximum energy from a solid material during combustion.

- Economy, achieved with the help of a fan with an adjustable speed, which, in turn, makes it possible to change the boiler power as needed.

- Fuel in a pyrolysis boiler burns much longer, than in conventional boilers, therefore, it is necessary to heat and clean less often.

Cons:

- High cost factory equipment limits its use in private households. The price of such a boiler 2-3 times higher, than usual.

- Long payback period.

- The need to use dry fuel. Recommended moisture content of wood materials - up to 15–20%. Otherwise, there will be no stable operation, the heating efficiency will decrease. The boiler may not work on damp firewood.

- If you use wood that produces a lot of resin (spruce, pine), then the oven compartments and elements quickly become dirty and difficulties arise with their cleaning.

- Ash may be released through the chimney.

- Dependence on electricity supply. The absence or frequent interruptions in the supply of electricity will not allow the boiler to be installed in remote regions.