Some useful tips on choosing and installing cast iron heating radiators

You are viewing the section Cast iron, located in the large section Types.

Cast iron radiators have been used to heat private houses, apartments and office premises for a long time now. a hundred yearsThe batteries are made of iron-carbon alloy.

The equipment has advantages and disadvantages, it continue to use in rooms with a modern design.

Content

Construction of cast iron batteries

Heating radiators consist of separate cast sections connected to each other nipple system.

The section consists of metal columns, inside which there is a space for the coolant. Places of connection of parts sealed with rubber or paronite gaskets.

The completeness of the delivery varies among manufacturers. Factories RF, Ukraine and Belarus produce products from 4 and 7 sections. Czech manufacturers – 10, Turkish - 8 and 10 sections.

The devices are made in height from 35 to 150 cm, depth – 6.5–50 cm. Batteries are mounted under window sills. Radiators are attached to the wall or installed on legs.

Technical specifications

Technical characteristics of cast iron batteries differ depending on their type and manufacturerThe table shows the properties of the most popular models.

| Model name | Depth, mm | Power, kW | Amount of coolant in section, l | Weight, kg | Working pressure, atm |

| MS-140 | 140 | 0.12–0.16 | From 1.11 to 1.45 | 7 | 9 |

| MS-110 | 140 | 0.125 | - | - | 12 |

| World Cup 1 | 70 | 0.075–0.11 | - | 4 | 9 |

| World Cup 2 | 100 | 0.1009–0.1423 | - | 6 | 9 |

| World Cup 3 | 130 | 0.1083–0.1568 | - | 7 | 9 |

| Demrad | 99 | 0,110 | 0.65 | 7 | 15 |

| Demir docum | 203 | 0.208 | 2.1 | 9.8 | 9 |

| Viadrus | 95 | 0.108 | 0.6 | 4.35 | 18 |

The appearance of the classic model

The usual models of cast iron radiators, known since Soviet times, are still being produced. The battery consists of sections connected to each other. The appearance of the structure resembles an accordionDetails with a rough surface have an unpretentious appearance.

New models are made in a modern design, the sections are made flat and with a smooth surface. Both types of radiators needs to be painted.

Benefits of using

Heating devices made of cast iron have a number of positive properties:

- High hydraulic resistanceThis allows the equipment to work with any type of coolant.

- Possibility of working with forced and natural circulation of the coolant.

- Efficient heat transfer by radiation and convection. Convection currents rise, warming the air. Radiation warms objects. The result is high-quality heating of the surrounding space.

- Resistance to aggressive chemical and abrasive influences technical water that has an alkaline environment and contains sand grains.

- Corrosion resistanceThe device will not rust during the summer period when it is without water.

- Long service life – 50 years. With proper care and timely cleaning, the equipment can work up to 100 years.

Flaws

The main disadvantage of radiators is their heaviness. Battery weight from 7 sections in the classic version it is almost 50 kg and it is impossible to carry out its installation and maintenance alone.

The disadvantages also include appearance simple models that do not fit into a modern interior. However, manufacturers offer improved and decorative radiators.

It is also worth noting long-term heating due to the thickness of the walls, but this is compensated by the retention of heat after the heating is turned off for several more hours.

Designer heating radiators

Domestic and foreign manufacturers offer designer models of radiators. The peculiarity may consist of:

- in a coating of gold or silver paint;

- in casting elements, bas-reliefs, various protrusions;

- in the "Retro" style.

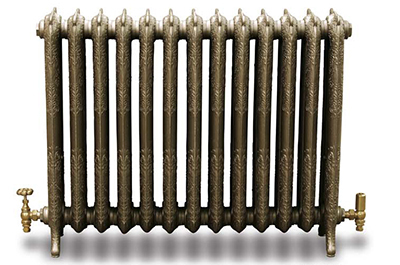

Photo 1. Designer cast iron heating radiator, covered with silver paint and decorated with bas-reliefs.

Decorative coating and the elements are usually applied to classic radiators. Such batteries are often made on legs, designed in the same style as the device.

Reference! Foreign-made equipment is sold at a high price. It is distinguished by its original design and less space for the coolant. Russian radiators in retro style are cheaper.

How to assemble and disassemble devices

Heating devices are sold already assembled, therefore, they are simply installed after purchase. But their service life is long, so periodic maintenance, repair, and equipment cleaning are required. Before disassembling the radiator, it must be removed.

Dismantling

Tools for dismantling a cast iron radiator:

- key No. 3 for pipes;

- grinder or other device that can cut the pipe;

- hacksaw;

- chisel;

- heavy hammer;

- rust cleaning brush.

Photo 2. Tools for dismantling the old battery are needed to quickly remove it from the brackets.

Radiators are removed in the summer, after draining the water from the heating system. Then dismantling is carried out:

- The lock nuts are unscrewed with a wrench on the pipes from the water supply side and fittings.

- Remove the battery from the brackets.

Attention! If it is impossible to turn the lock nut cut pipes, supplying hot water.

Disassembly

The tool required to disassemble a cast iron radiator:

- key (for a modern model you will need a key 1 inch, for a Soviet-style device – 5/4 inch);

- Radiator key 4.0 x 2.4 cm (you can make it yourself by screwing a rectangular tip to a reinforcement rod) with a hole for the lever;

- adjustable wrench No. 3 or 2;

- inch pipe, 0.5-1 m section;

- construction hair dryer;

- chalk.

Photo 3. The nipple nut is unscrewed using a radiator key after the battery has been removed.

The order of disassembling the device:

- Prepare a level area, place the removed radiator on it.

- For blind plugs, the direction is determined, in which they are unscrewed, and turn them away.

- Using a radiator wrench, loosen the nipple nut in accordance with the direction of the thread. Turn over alternately from top to bottom. For old devices, heat the connection points with a building hair dryer.

- The sections are spaced at a distance of 5 mm. They are not spread wider, as this can lead to thread breakdown and distortion. An inch pipe is used as a lever.

Important! On plugs, stoppers, nuts of modern heating devices there is thread direction designation (D and S).

Assembly

Assembly tools:

- radiator or gas key;

- nipples;

- rubber or paronite gaskets;

- tow;

- silicone or paint;

- plugs.

Radiator assembly procedure:

- Unscrew the old plugs on the ends.

- Screw in the nipples, paying attention to the direction of the thread. A gasket is placed between the sections.

- The connection is clamped evenly. top and bottom.

- When installing an additional section, install end caps.

- The radiator is installed into the system.

- To check the integrity and tightness of the assembly the system is filled with water.

How to calculate the number of sections?

To maintain the microclimate of a living or working space, it is necessary to correctly calculate the required number of sections of heating devices. two options calculation:

- By squares premises;

- on the heated one volume.

By area

The following is taken as the norm:

- 120 watts per 1 m2;

- one window opening;

- one external wall.

When adding windows, the number of sections increases. For example, for a room with average insulation area 18 m2 you will need: 18 × 120 = 2160 (W).

When installing the MS model – 2160 : 140 = 15.43 (sections).

Rounding is always done upwards. That is, in this example, for heating a room with an area of 18 m2 will be required 16 sections cast iron radiator.

By volume

The volume indicator is used when it is necessary to heat a room with high ceilings. For brick buildings, the standard is 34 W per 1 m3. For panel houses it will be necessary 41 W.

Approximate calculation for a room with parameters 6m x 6m x 5m in a brick house: 180 m3 × 34 W = 6120 (W). Next: 6120 : 140 = 43.71 (sections).

So, to heat the volume 180 m3 will be required 44 sections.

Approximate price

Cast iron radiators Russian production is at a standstill 340–380 rubles per section. Foreign products have a higher price:

- Viardrus (Czech Republic) – 450 rubles;

- Konner (China) – 500 rubles;

- Demrad (Türkiye) – 600 rubles;

- Nostalgia (Türkiye) – 2000 rubles;

- Demir docum (Türkiye) – 2400 rubles;

How to choose a device?

Once the design has been determined, a radiator is selected based on the required calculated power for heating the room and the parameters of the room itself.

- According to passport data. The equipment passport contains information about the capacity. The required number of sections varies for different battery models.

Pay attention to the height and depth of the device segments so that it is correctly positioned under the window sill.

- By manufacturer. Production of heating equipment of this category in Russia established and successfully developing. Manufacturing is carried out in Bryansk region, Nizhny Tagil, ChelyabinskThe cost of the equipment speaks in favor of the domestic manufacturer.

In the Republic Belarus cast iron batteries are manufactured good quality in the same price segment. German, American, Italian, Turkish radiators have a more attractive appearance and reduced consumption of coolant. But the cost of such equipment is high.

Useful video

From the video you can learn about all the advantages of installing a cast iron radiator, as well as the existing disadvantages.

Why do users choose cast iron radiators?

Despite the presence of alternative offers on the heating appliances market, consumers continue to use cast iron equipment. The main reasons are their durability and heat transfer capacity.

It plays an important role resistance to damage chemicals and abrasives. Cast iron is irreplaceable in central heating systems, as they contain the most aggressive heat carrier.

The third reason for using is – creating a vintage interior, for which modern laconic models are not suitable.