Heating in seconds! Features of heating from a boiler, diagram of connecting the device to the system

It is important to choose the right working scheme heating from an indirect heating boiler (IHB) in buildings that need to be heated in cold winter conditions.

Pipeline system must function well and reliably, since the operation will be carried out at high pressure.

Content

Where to place the device

Installation of equipment begins with choosing a location. It is recommended to place the water heater near the heating boiler or central heating outletThe closer the unit is to the boiler, the more effective the process of heat transfer from the heating system to the hot water supply will be.

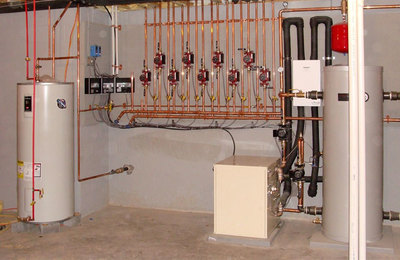

Photo 1. Floor-standing indirect heating boiler (left), installed next to the heating boiler (right).

Indirect heating boiler is located in the boiler room, and there are also ways of fixing in the corridor, bathroom and other utility rooms. In such options, there is a significant loss of heat. If hot water consumers are closer to the indirect heating boiler, the heat loss in the DHW will be significantly reduced and the time of supply of hot coolant in the system without circulation will be reduced.

General rules for the placement of BKN

- Wall, on which the boiler will be located, must be of load-bearing type — concrete or brick. The unit is not installed on foam concrete, wooden, plasterboard partitions.

- It is recommended to choose a location closest to the layout of central water communications.

- There should be an electrical outlet nearby. for the convenience of direct connection.

- In the place where the device will be located, provision should be made some free space for ease of repair and maintenance.

- Place horizontal or vertical types of equipment better in the area close to sewer pipes to remove water from the storage system.

Installation of BKN in a boiler room

Exists four ways of installation indirect heating boiler in the boiler room - wall, horizontal, vertical and floor.

The first ones have fittings for mounting on the wall surface, the second ones do not have such a fastening part, and the set includes stands for floor placement.

Wall-mounted models have a small size and volume from 30 to 200 l, floor from 200-1500 lThe system for installing the BKN on the wall is the same as the mounting of a conventional electric water heater - the same anchors and installation.

Important! When installing an indirect heating boiler, it is necessary to place pipes for supplying and removing the coolant towards the boiler. Otherwise, you will have to construct a complex system of pipes, bypasses, corners and the pipeline will be incorrect. You should get two straight fittings that go from the heating system.

Connecting an indirect heating boiler

It is better to install the unit according to the diagram, Additionally, the following materials will be required:

- distribution manifolds;

- valves;

- three-way valve;

- check valve;

- hydraulic arrow;

- pressure relief valve.

Connection:

- Having decided on the location and type of fastening of the device, the main task when starting the system will be ensuring sufficient water supply.

- Make a connection in the pipeline for the water heating device. The connection is made using flexible hoses. It is recommended to mark the cold water inlet with a blue marker.

- After The pressure relief valve is connected.

- To ensure trouble-free drainage during maintenance, A tee should be installed to connect the hose.

- All joints need to be carefully sealed., the most suitable material is fum tape, tow or silicone sealant.

- The hot water taps are connected to the corresponding outlets on the unit. When connecting to the water supply network, it is necessary to take into account that cold water is supplied to the lower part of the device, and hot coolant comes out of the upper zone. The circulation point will be located in the middle part.

- The next step is electrical work.. Connecting the BKN to a socket or to a power distribution board. The second option requires mandatory grounding. It is recommended to install an automatic switch near the device. The extended wire is stripped up to 10 cmThe exposed phase is screwed to the terminals - from the water heater to the lower ones and from the panel to the upper ones.

- When starting the electrics, you need to make sure that the indicator light has turned on. In the opposite case, the power supply is turned off and the connection is checked again.

- The heating mode is adjustable according to the recommendations specified in the operating instructions.

Reference. When the system is first started, it is recommended to supply water with weak pressureto check the correct connection and make sure there are no leaks.

How to install on the floor or wall?

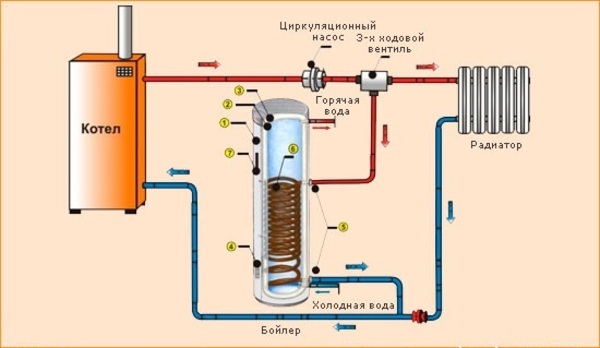

Connecting the indirect heating device to the boiler will allow you to accumulate hot water, distributing it across several points — heating radiators, in the kitchen and bathroom. The schematic image shows the connection of the KN water heater and boiler to the communications system.

Wall mounted fastening:

- Using a tape measure and a marker they are marking a place for hanging the device. In the wall drill a hole, install mounting anchors or staples.

- The walls on which the boilers are installed must be load-bearing, it would be good if this were the case. concrete or brick surface.

- It is recommended to place the water heater as high as possible.so that the equipment does not interfere if it is installed in a common area.

Photo 2. Indirect heating boiler of wall type. The device must be installed on a load-bearing wall.

Floor standing installation:

- Installation of indirect heating equipment is performed on a flat surface. It will be necessary to create a small platform, about 10 cm highThis is necessary so that the floor heater is located above the boiler level.

- Inlet and outlet pipes should always be directed to the side boiler apparatus.

- In order to avoid dismantling the device in the future, the installation location of the boiler must have enough free space for further maintenance and repair.

Attention! Not recommended for use in construction corrugated hoses, they cannot withstand the pressure force, which leads to system failures and the creation of a dangerous situation.

Connection diagram of the heating and hot water supply system via the BKN

After the BKN is installed in its place in the boiler room or in the bathroom, you can begin connecting the unit to the heating system. For installation work a minimum number of tools will be required.

The indirect heating boiler has 4 pipes, which serve for the entry of cold water and the exit of hot water from the DHW system. If a circulation system is provided in the DHW, the last pair of pipes will be the entry for hot water from the DHW structure and the exit of the hot coolant back to the DHW with circulation.

Photo 3. The diagram of the connection of the boiler to the boiler and the heating system. The hot coolant is marked in red, the cold one in blue.

When the taps at the points of analysis are in the closed position, the coolant moves through the DHW system, heating up to the required temperature by the boiler. When the tap is open at the point of connection, water flows to the consumer. To connect the BKS, you should connect two upper pipes to the boiler heating and two lower pipes to the hot water supply.

When combined water heating units are operating, the water in the BKN will be heated both by the heat carrier and, if necessary, heated by electric heating elements built into the BKN.

Important! If the pipeline is long, you should use a boiler connection diagram that provides for hot water supply recirculation. This option will ensure instant supply of hot water to the consumer.

For example, the BKN and the boiler for providing hot water supply are located in the basement of the house.

Features of connecting a KN boiler to a gas boiler

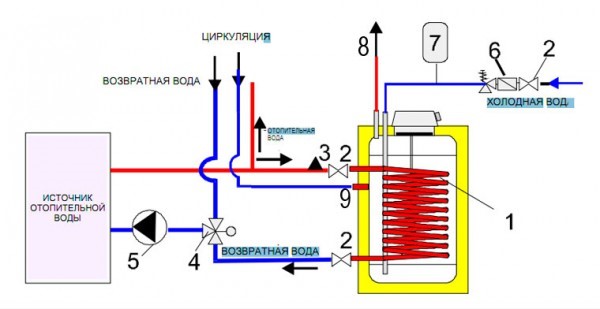

All boiler piping schemes in the general heating and hot water supply of the residential premises must be observed - the functional relationship of the water heater with another device, which is also a heat source, the role of which is played by a gas boiler. As a result, the following mechanism should be obtained (shown in the picture below), using control elements: The boiler thermostat, three-way valve, pumps or collectors distribute the gas combustion energy to provide heat to the heating and hot water supply system.

Photo 4. Boiler connection diagram. The numbers below indicate the component parts of the structure.

- Technical device, in which heat exchange takes place between two media having different temperatures (heat exchanger).

- Shut-off valve.

- Air bleed valve in the contour.

- Three-way valve.

- Pump for circulation of the coolant.

- Safety valve.

- Expansion tank.

- Hot water outlet.

- Retraction in the pipeline.

This circuit is a two-circuit one.

Heating circuit:

- Red marking line indicates the supply of hot water, the arrow indicates the direction of circulation of the coolant to the radiators.

- With a blue line The return of cooled water from the radiators to the valve (three-way) is noted, through which and the pumping device the liquid is directed back to the boiler for heating.

Water heating circuit in the boiler:

- The red line is marked from the boiler, passes through the air bleed valve and the shut-off valve. This is how the heated coolant is supplied to the boiler heat exchanger.

- The blue stripe from the heat exchanger indicates water return through valve and pump, then it is fed into the boiler.

Useful video

Watch the video, which tells about the features of the indirect heating boiler and the options for connecting the device.

Features of indirect boilers

Indirect water heaters use heat from the heating system. These The devices are economical and are used mainly in country cottages, which have an autonomous type of heating system. To get the maximum energy and use the device for a long time and safely, correct calculations of the heating scheme are required.