A new revolutionary type of fuel: how to use briquettes for heating and is it possible to make them yourself

Heating briquettes – a relatively new type of raw material for kindling, which is gradually replacing wood and coal used for these purposes.

Made from waste agriculture, plant growing, from the processing of boards, etc., they effective, easy to use, save money on electricity, are a good alternative to other, not at all cheap materials.

This type of fuel is great suitable for combustion in solid fuel boilers any type and does not require any changes in the design of the equipment. But how profitable is such heating? What distinguishes briquettes from other types of fuel? Which type is better and how much may be needed to heat a private house?

Purpose of briquettes

The use of briquette products allows for quite good heat an area of up to 200 m2These may be premises:

- warehouse and workshop in production;

- utility rooms and boiler rooms;

- houses, cottages, mansions and summer houses personal use;

- baths, saunas etc.

Features of production

This fuel is produced by pressing its components. using high pressure, in some cases - with the simultaneous use of temperature exposure. Intra-briquette gluing in this version provides lignin - a material of natural origin, located in plant cellsThe use of high temperatures allows the product to retain its shape, gives it strength, which has a positive effect on the safety of the briquettes, as well as their packaging and transportation.

Reference. The fuel material production scheme itself is simple and involves initial grinding of the main component briquettes, pressing it and, if necessary, heat treatment.

To ensure better combustion, some versions of this type of fuel product are made through holesThe resulting briquettes are then packaged (except for protected types) and sent to consumers.

They produce such raw materials in several variations:

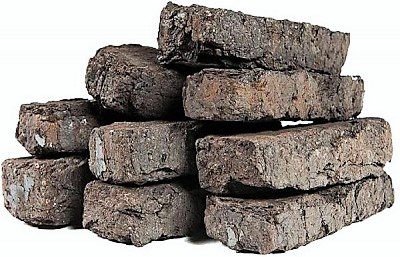

- RUF - bricks with rounded corners;

- Nestro — cylinders of various lengths;

- Pini-kay - elongated polyhedrons with holes in the middle, which, in addition to being pressed, are also fired, due to which they acquire greater strength.

Advantages

Briquette fuel has become increasingly popular since its appearance. And this is quite understandable, since advantages its advantages over other heating methods are obvious:

- high performance - give off twice as much heat as firewood;

- comfort - they are easy to light, do not produce sparks, burn to the ground without creating any soot that pollutes the room and air;

- burning duration - with good air access continues approximately 2.5 hours, and in the supporting mode of smoldering the briquette bookmark can burn up to 7 hours, providing the room with warmth;

- zero waste - there are practically no combustion products in “euro-firewood”;

- smokelessness - one of the main advantages of this heating. There are absolutely no risks of harm to health, because during the combustion process carbon dioxide is practically not released.

Important! The most important thing about briquette fuel is that it is distinguished by its perfect security for a person.

The required amount for heating a private house

Fuel briquettes have a lower consumption, which makes it possible to reduce costs compared to electricity or other types of raw materials. But the main thing is that they generate more heat, than the same firewood or any type of coal.

This is especially noticeable when heating is organized using solid fuel boilers. But even with stove heating, you can feel the difference well.

Besides, Firewood and coal wear out the stove much faster: form carbon deposits that disable chimneys, which, of course, is not observed when using briquette materials. And storing them is much easier - they don't take up much space.

Only 2.5 tons standard briquettes will be needed for the season in order to heat house 100 m2If you compare the same amount of coal and firewood with their cost, the advantage in favor of briquettes will be obvious.

Types of briquettes

Since today there is a new fuel market many kinds such products, it is necessary to have a good understanding of the main representatives and their heat output.

Woody

This is a fuel that has cylindrical shape and characteristic color, is mainly produced from wood waste - sawdust, shavings, substandard materials, dead wood.

These briquettes are distinguished by:

- insignificant humidity - only 10% (wood in its solid form has - 40 - 60%);

- high heat capacity;

- uniformly distributed density;

- smokelessness;

- long lasting combustion period (at least 4 hours);

- education waste, allowing their subsequent use to ignite another batch;

- environmental safety (emit a small amount of carbon dioxide);

- ease of storage and transportation.

As for heat transfer, the raw material from wood waste is 4500 kcal/kg (firewood does not exceed 3000 kcal/kg).

Coal

This artificial fuel is obtained from screenings of coal. It is first andcrushed, then pressed, adding binding agentsThis material always burns well, it is only important to ensure sufficient air flow.

It is completely possible to use coal briquette safely, since it does not emit carbon dioxide when burned. It is quite reasonable that this raw material is often used in houses and cottages when burned in boilers and stoves.

The distinctive features of such fuel include:

- high density;

- low moisture capacity;

- opportunity continuous flow control and the process of combustion of the product;

- good flammability, which allows you to quickly warm up the room;

- ease of transportation (quite strong briquettes do not crumble);

- formation after combustion ashes, and not slag, as is the case with coal.

Important! Coal dust briquettes provide the longest burning timeWhen heating a room, you need to put them in the stove only 3 times a day.

Coal briquettes burn predominantly 6 - 7 hours, if a good air supply is provided - then up to 10 o'clock, which leads to long-term maintenance of the temperature regime. The heat output from them is 5200 kcal/kg.

Peat

Fuel produced from peat (it was previously dried and then pressed). These briquettes are burned in boilers, stoves, fireplaces, and also in fires.

Their features primarily include:

- possibility of application in all types of furnace equipment;

- ease of use (the product is ready for use);

- long burning period;

- opportunity using combustion residues as fertilizer;

- low content of additional impurities;

- accessible price.

The heat transfer of peat briquettes is good - 5500 - 5700 kcal/kg.

Important! When using such raw materials, you must always remember to be careful and not place it near open fire sources - peat highly flammable.

From the husk

Now everything that was previously recyclable is not thrown away. This is straw, and processed products of sunflower and buckwheat, rice, oats and ryeHeating materials are produced from waste, the most common of which are sunflower husk briquettes.

Features of this raw material:

- perfect harmlessness;

- acceptable price;

- ability to support burning for a long time;

- convenience in storage and transportation.

This heating material is characterized by excellent dryness and good combustion: 100 kg of raw materials will provide heat comparable to that produced by combustion 150 - 200 kg of firewood.

Due to the presence of oil, the heat output of husk briquettes is almost the same as that of their coal counterpart - 5200 kcal/kg. True, such fuel has high level of waste, if compared with other types of briquettes. But at the same time it is quite popular among buyers.

Fuel briquettes at home

Turns out, the production process is so simple, that you can prepare briquettes for heating yourself. The main thing is to have raw materials and equipment, which is important for pressing the material. The simplest thing is manual screw drive tank. Some use a mechanism that pushes out the bricks. And experienced craftsmen also use screw press, with the help of which it is possible to obtain products of higher quality. Of course, it will be necessary to spend a lot of money to provide such equipment.

Reference. To create the necessary pressure and obtain products similar to industrial production, it won't work at home under any circumstances.

People make briquettes at home from all kinds of flammable raw materials: paper, cardboard, leaves, straw, sawdust, husks, shavings, dry plant stems, manure, etc. Water, clay, starch and components with adhesive properties are also used in the work.

Photo 1. A machine for producing briquettes, with the help of which raw materials are pressed into small “bricks”.

The technology for producing briquettes is quite simple. Sawdust (or other crushed products), placed in water, they add there clay (proportion 1:10), Fine stir, pour in adhesive substance (for example, inexpensive wallpaper glue). The finished mixture is placed in a homemade pressing device and squeeze.

The resulting briquettes take out of the mold and lay out for drying in the sun. After complete drying, they are ready for use. But it should be noted right away that homemade ones will not be as strong as industrially made forms.

Useful video

Check out the video for a thorough comparison of birch firewood and two types of fuel briquettes: purchase method, price, density, quality and burning time.

Storage Features

Fuel briquettes if necessary you can buy in reserve. Due to their high density and small size for storage it doesn't take up much space. For example, 2500 kg briquette bricks can be placed in 1 cubic meter.

To ensure that they do not lose their properties, you should adhere to the basics storage rules:

- Humidity level in the room where the briquettes will be stored, should not exceed 80%.

- For storage in winter use closed spaces with a good roofto protect the briquettes from precipitation.

- But there is no need to worry about fire safety measures, that's it the fuel does not ignite spontaneously.

Briquetted raw materials - not only cost-effective but also efficient heat source. It is especially suitable for heating a solid fuel boiler as an additional way to ensure combustion duration. But in other cases, briquettes show only good results, which ensures their ever-increasing popularity.

Comments