Deviation from the norm is dangerous! How to prevent pressure drops in the heating system in a private house?

Water heating systems have long gained popularity as a simple and effective way of heating living spaces.

Undemanding to types of fuel, universal in the choice of configurations, they remain popular to this day.

The cost of its operation and the comfort of the people living in the house depend on how correctly the heating system is designed, installed and adjusted.

Content

Water pressure standards in heating systems of a private house

Water heating systems are:

-

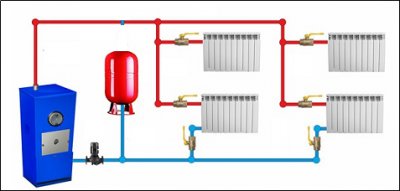

Open. The system communicates with atmospheric pressure through open expansion tank, installed at its very top, and the boiler is installed at its very bottom.

In this case, water circulates through the pipes according to the laws of natural convection - the lower layers of water heat up and rise to the top, and the colder and heavier ones sink down, where they heat up again.

- ClosedIn closed systems, the water pressure is isolated from the atmospheric pressure, and the water moves through the pipes of the circuit with a special water pump.

What should be the operating parameters in an open circuit?

The pressure in an open circuit is determined by the hydrostatic pressure of its water column. The water column is 1 meter creates an increase in pressure per unit surface area at its lowest point, equal to 0.1 kgf/cm2, or 0.09 atmospheres.

Reference! To calculate the pressure at a selected location in an open system, it is necessary to measure the height from the measurement point to the water level in the expansion tank, adding 0.1 kgf/cm2 for each meter of water column.

The pressure in open circuits is self-regulating and do not require balancing, their design is less complex and requires lower maintenance costs.

However, the laws of heat exchange establish height restrictions of such a system, associated with uneven heating of the coolant and, as a result, a decrease in its overall efficiency.

Partially solves this problem installation of a circulation pump, increasing the flow of coolant, however, an open heating circuit, due to its limitations, is only suitable for single-story houses.

Normal values in a closed system

In practice, closed systems are more often used due to their wider application possibilities. In particular, if the house has two or three floors, and one pump cannot cope with maintaining the water flow, additional circulation pumps can be installed at various points in the circuit, connected in series or in parallel, which reduces the load on the boiler.

The working pressure of a closed heating system is usually considered to be the value at 1.5-2 atmospheres. The maximum permissible working value, usually regulated by a safety valve, is 2.5 kgf/cm2.

How does the adjustment work?

The pressure in a closed heating system is regulated pumping water into the heating circuit through its connection to the cold water supply system, as well as membrane steel expansion tank.

One half tank separated by a membrane, filled with air with the so-called excess charging pressure, and the other with circulating water.

As in open heating circuits, the membrane tank serves to contain the expanding water during its operating heating, and also reduces pressure fluctuations (water hammer) when the water flow suddenly stops.

The membrane tank charging pressure when the circuit is not working is equal to the water column pressure. The standard factory expansion tank charging value is 1.5 kgf/cm2, and the maximum value for which the equipment is designed is up to 3 atmospheres.

Causes of pressure drop

The system's operating pressure level is not always at the required level and may fall or rise.

The main reasons for its decline:

- Leaks coolant. Leaks can appear in all elements of the heating circuit - in pipes, radiators, and are usually associated with manufacturing defects.

Leaks at connection points often occur due to loose fasteners or connection damage during its assembly.

- Wear structures. Usually caused by incorrect installation contour or nviolations of operating standards — too high pressure or significant pressure drops, high water temperature or high water hardness. Individual system elements, including the circulation pump, have a warranty period, and after its expiration, their performance may decrease, requiring adjustment or replacement.

- LimescaleIt appears when the water heats up. to too high temperatures. Scale is hard salt deposits, formed on the heating surfaces of the heat exchanger. Accumulating in the heat exchanger, the scale blocks the flow of water and reduces the operating pressure.

Important! Too much "hard" water contains increased amounts of oxygen, chemical impurities and salts that form rust deposits. Hard water may be present in the system due to frequently replenishing it with fresh water, including due to coolant leaks.

What causes the sharp increase?

The increase in pressure in the heating circuit may be caused by the formation of air pockets. Traffic jams can occur due to incorrect wiring contour, not taking into account its bends and slopes, and also due to leaks or his damage (poor sealing of joints, coolant leaks).

The cause of the formation of traffic jams can also be low coolant pressure, creating voids filled with air, as well as incorrect filling of the circuit with coolant at the stage of its start-up.

The absence or ineffective operation of air intake devices or air release valves allows air locks to accumulate especially quickly.

Air locks form areas difficult for water to pass through, locking its movement in individual nodes of the structure, thereby increasing the water pressure.

The following may become an obstacle to movement: coarse filters (mud traps), usually installed in several sections of the heating circuit. Untimely cleaning of mud collectors (less than once a year) can also create conditions for the occurrence of the above situations.

Control methods

Monitoring pressure indicators in a closed system, in conjunction with the operation of the air vent and safety valve (the so-called safety group), is a prerequisite for its safe and effective operation.

Manometer

To control the required values, use pressure gauge — a device that shows on its scale the pressure of a liquid or gas in a closed circuit. Manometers usually have 2 scales, showing values in kgf/cm2, bars or atmospheres. The pressure gauge can be combined with a thermometer showing the temperature of the measured coolant.

Photo 1. Pressure gauge for measuring pressure, shows values in bars and pounds per square inch, manufacturer - "FERRO".

For a private house, they are usually used spring pressure gauges because of their simplicity and reliability. The pressure gauge measurement scale has a wide range, but a more convenient one is usually used scale from zero to four atmospheres.

Important! The pressure gauge must have necessary seals and stamps upon passing the test, be undamaged, and the pressure gauge needle should return to the zero position in the absence of pressure in the system.

Usually a pressure gauge crashes into the highway at the outlet of the boiler, at the minimum possible distance from it, and is located so that it can be conveniently read.

Air vent

Automatic or manual air vent is placed in at the highest point heating system, and, if necessary, in other places, and is structurally intended for automatic or manual air removal without compromising the tightness and leakage of the coolant.

Safety valve

Safety valve — a special protective device designed to protect the system from exceeding the permissible pressure, which is usually about 2.5 atmospheres.

If the specified value is exceeded, the tightness of the system may be broken and an emergency situation may occur. Such a valve is called bypass and is installed on the outlet pipe of the heating boiler.

Why check for leaks?

In order for the system to function properly during the heating season, it is important to check the condition of its equipment and identify all the weakest and most worn-out areas. Such a check is carried out regularly and is called pressure testing.

The test is usually carried out at the end of the season by pumping fluid into the system using special equipment that raises the pressure above the working pressure. 1.2-1.5 times.

Pressure testing reveals all weak, breaking or leaking areas structures that require inspection and preventive maintenance. After inspection and repair, the heating is put back into operation.

Useful video

Watch the video to learn why the pressure in your heating system may drop and what to do in such a situation.

Optimal performance during the heating season

Optimal pressure values in the system largely determine its thermal efficiency and significantly extend its service life. Fall or rise values on 0.2 atmospheres from the working norm at 1.5-2 atmospheres is sufficient reason to look for its cause.

This allows notice and eliminate the malfunction in time and bring the system to an optimal operating mode without the development of emergency situations and unplanned repairs.

Comments