And let it always be warm! How to make a heating system in a private house with your own hands?

The choice of heating system depends from the accuracy of the calculated data and the characteristics of the heated room. For heating private houses, they most often use water heating.

To install the system yourself, it is advisable to have certain knowledge in plumbing and construction.

Content

Components of water heating in a private house

The water heating system has become widespread due to its reliability and ease of operation.

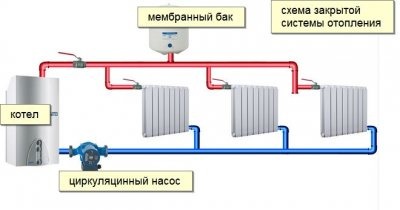

Its main elements — boiler, expansion tank and radiators. Additional equipment includes a circulation pump, thermostat, safety valves and ventilation openings.

For water heating system All available fuel options are suitable. The reliability and durability of the installed equipment depend on the choice of heat generator.

Gas boiler

Gas boilers designed for heating a private home, are divided into two groups: floor and wall mounted. The most convenient option — a wall-mounted gas boiler, since its use does not require the installation of a chimney. The device has high power, does not require electricity and is capable of heating a large room. For continuous operation, constant access to a gas pipeline is required.

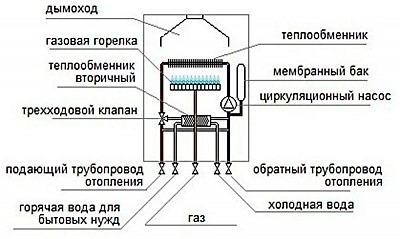

Scheme and principle of operation

The boiler is a closed vessel. Key Components - burner, combustion chamber, heat exchanger and control elements.

Hot water or pressurized gas is used to retain and distribute heat throughout the room.

When water boils at atmospheric pressure, its volume increases by approximately 1600 times, which makes the use of gas boilers unsafe if not properly maintained.

The process of fuel combustion takes place in the combustion chamber, and heat is transferred to the water through a heat exchanger.

The controls regulate the combustion rate, fuel supply, water temperature and boiler pressure.

Hot water produced by the boiler, spreads throughout the entire pipe system.

Installation

Before installation, make sure that the installation location of the device is suitable for further use of the boiler. Provide open access to water, gas and electricity in advance. Get rid of flammable substances. It is advisable to check all valves and taps before final installation so that you have the opportunity to eliminate the leak.

Number of circulation pumps and pipes varies depending on the size of the system. If an insufficient number of elements are used, the risk of failure of not only the heat generator itself, but also the entire system as a whole increases.

For safety reasons, please provide ventilation. Ventilation type depends on the specific boiler modela. Please read the installation instructions supplied with the heat generator in detail.

The gas supply system differs depending on whether you are using propane or natural gas.

After connecting the boiler to the pipeline, turn on the water supply using automatic valve. Make sure there is no leakage before placing the device into permanent operation.

Attention! If you do not have a license to install gas equipment, Contact a qualified professional.

Pros and cons

The advantages of using a gas boiler include:

- Energy efficiency. Heating a room requires less gas than any other fuel.

- Price. Natural gas is one of the cheapest fuels for home heating.

- Convenience. Natural gas heats water faster than electricity.

- Environmentally friendly. Natural gas does not generate dirty emissions.

Disadvantages of a gas boiler:

- Expensive installation. To bring gas and pipelines to a private home requires a considerable amount of financial investment.

- Safety. Gas leaks are often the cause of explosions and fires in residential premises.

Electric boiler

These boilers operate on a similar principle to gas boilers, but Electricity is used as fuel.

Photo 1. Electric heating boiler from the outside (left) and its internal structure (right).

These systems offer great space savings as they combine the water heater and central heating boiler into one unit. Basic elements - pump, switch and thermostat.

Operating principle

The electric boiler is connected to 220-volt circuitThe temperature is controlled by a thermostat. As soon as the temperature drops, the thermostat closes to ensure the supply of electricity and opens again when the temperature reaches the set limit.

When the hot water tap is opened, the cold water water enters the tank through a dip tube, the decrease in temperature causes the thermostat to operate. When cold water enters the upper part of the tank, the temperature on the upper thermostat drops.

Installation

Installation and wiring depend on the height of the buildingIf the house has more than one floor, the boiler is installed in the basement and the expansion tank in the attic.

In order for the system to heat the entire room, take a serious approach to the choice of heating devices, the quality and quantity of radiators, the location of all parts of the heating system and calculate the area.

Calculate the number of radiators in advance (it depends on the number of rooms and the size of the system itself). The pipeline must pass through both the basement and the attic.

Important! The main stage of boiler installation is connecting it to electricity. It is advisable to entrust this work to a professional craftsman, if you don't have enough experience.

Pros and cons

The advantages include:

- heating efficiency;

- compactness;

- easy to install;

- safety;

- ease of use.

Cons:

- dependence on the power grid;

- high price;

- small heating area.

Solid fuel heat generator

Heat generator, heated with wood, peat or coal, is used much less frequently than gas and electric counterparts. Fuel is fed into the boiler through the door, after which it heats the entire structure. The chimney and ash pan throw out waste such as smoke, soot, ash and foreign debris. Maintenance of a solid fuel boiler requires a lot of time and financial costs. An additional inconvenience is the need for constant temperature control.

Photo 2. Solid fuel heat generators used for space heating. The devices are quite massive and require a lot of space.

Operating principle

As the solid fuel burns, it gradually heats the cold water, after which the heat is distributed throughout the room via a radiator. Under the influence of high temperatures in conditions of lack of oxygen, wood (or other type of solid fuel) breaks down into pyrolysis gas and coal. In the process, oxygen and pyrolysis gas mix, as a result of which the latter begins to burn and generate heat.

Installation

When installing a solid fuel boiler, an important role is played by correct connection of equipment to the system. It is not recommended to carry out installation work without experience in handling boiler equipment, since an incorrectly installed boiler may cause a life-threatening explosion.

When installing a boiler, most of the work is spent calculating the slope and installing the pipeline. The chimney is installed last, but if installed incorrectly, smoke will flow back into the room. Before installation, concrete the floor in the room where the heat generator will be located, since heat coming into contact with wood or fabric can cause a fire. The construction of a solid fuel boiler consists of the following stages of work:

- preparation for boiler installation;

- installation of boiler equipment;

- wiring;

- installation and connection of the entire system to the chimney;

- boiler start-up and efficiency testing.

First phase of works is the preparation of the floor for the installation of the boiler. An alternative to concrete can be steel (less often gravel).

The most difficult is second stage. Since the boiler is installed on a pre-prepared base, all joints between the heat generator and the floor are filled with silicone or mounting foam.

Next stage — connection to the hot and cold water supply system. The final stage — installation of the chimney and its connection to the boiler. All work is carried out in accordance with specifications and compliance with fire safety regulations.

Pros and cons

Advantages of solid fuel boilers:

- relative environmental friendliness;

- recycling of wood waste;

- wear resistance of equipment.

Flaws:

- large dimensions of the system;

- high cost of equipment;

- the need to comply with fuel storage conditions;

- the importance of regular boiler cleaning;

- unstable prices for timber and coal.

How to make a water heating system with your own hands

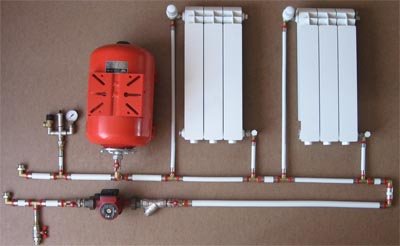

The system requires the installation of such elements as: circulation pumps, distribution manifolds, expansion tank, measuring instruments and shut-off valves.

All holes for pipes are prepared in advance, as boiler models differ from each other. The method of connecting pipes is selected depending on the material.

Pay attention to such an element as radiators. They can be improved and standard. Reinforced radiators are designed for system pressure 16 bar. The installation is carried out in such a way that the distance from the floor to the radiator is 10-12 cm And 2-5 cm from the wall. At the inlet and outlet of the radiator, blocking and regulating valves are installed. Thanks to them, it is possible to regulate the temperature and flow of water.

Reference. Use a special sealant for sealing threaded connections. In this case, they will serve you much longer.

Expansion tank

Expansion tanks are designed to reduce the pressure inside the boiler. The main elements of the device are an air chamber, a membrane and a water chamber.

There are two models of expansion tank - open and closed.

Features of the open model are as follows: if the liquid in the tank significantly exceeds the maximum level, and the pressure increases, then the water returns to the supply line.

Closed model blocks water with valves. The problem with this system is that when the pressure increases, the water does not leave the tank. This leads to deformation of the equipment and destruction of welds.

Radiators

There are two types of radiators - bimetallic and cast iron. It is very difficult to distinguish a bimetallic radiator from its aluminum counterpart by appearance. Despite this, a bimetallic radiator is heavier than an aluminum one. by 50-60%.

A bimetallic radiator uses two metals — steel (inside) and aluminum (outside). Aluminum provides an effective heat flow, due to which the radiator body heats up faster. The core of the structure is made of steel to protect the radiator from the negative effects of alkali and other aggressive impurities that are present in old heating systems. The steel coating allows the device to be used even at high internal pressure.

Photo 3. Bimetallic heating radiators. Currently, they are the most popular.

Cast iron radiator It will take longer for the body to heat up completely. This is due to the size of the cast iron radiator. The thermostatic valves of the device help eliminate wasteful heating and regulate the temperature throughout the house.

Accessories

In addition to the basic elements, the heating system also requires additional ones in the form of various fittings.

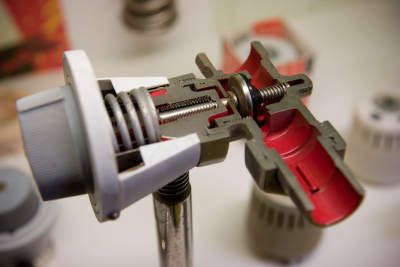

Valves

The valves are intended for removing condensate, air and gases from steam systems.

Eat three main factors, which play an important role when choosing valves, are the size, body shape (angled or straight) and control type (thermostatic or manual).

Most radiators have a horizontal system, which requires the use of angle valvesIf the connections rise from the floor, straight models are required.

Thermostatic valves are self-regulating system, which works in combination with temperature, pressure regulators and time-setting devices.

Valves

During operation of the heating system appears excess air.

To prevent this phenomenon, an air valve is used.

Depending on the purpose, there are two types of safety valves.

Some are for removing air from the system, others are for preventing the backflow of water in the pipes.

Cranes

The choice of a faucet is determined by convenience and durability. Regardless of which model you choose, installation occurs in the usual way. The only point that is important to note is replacing traditional gaskets with waterproof putty. Constant high temperatures can damage the faucet, which means frequent replacement of gaskets. Try to check the taps daily for leaks.

Pressure gauges

Manometer determines the pressure of gas or liquid in pipes. Often installed immediately during the installation of drainage.

Making a pressure gauge yourself is not difficult. You will need U-shaped piece of plastic tube, half filled with water. The upper ends of the U are connected to two taps. When a certain difference in pressure appears between the taps, water moves from the left side of the tube to the right. The difference in water levels helps to correctly determine the pressure difference.

Mayevsky taps

Excess air often accumulates in the heating system, which disrupts normal circulation within the pipe system. The Mayevsky crane is a rotating cone and helps to cope with this problem.

When open, the tap gradually releases all excess air. As soon as water starts flowing from the tap, This means that all excess air has been released. After this, the crane is returned to its original position.

The Mayevsky crane is installed if there is no water in the system (to avoid leakage). If the crane is constantly kept open, it will quickly become unusable.

Hydroaccumulator tank

To increase the efficiency of the heating system and reduce emissions, a hydraulic accumulator tank is used. It acts as a large flask, keeping warm for a long timeThis tank is especially important when using a solar battery.

Natural circulation system: operating principle, installation features

For systems with natural circulation, no pump installation is required.

Operating principle

In a system with natural circulation, it is observed the difference in density as the water in the boiler heats up. In more complex designs, warm air rises and exits the top of the unit, and cool air enters the system through the bottom. This design uses little energy.

Divorce

Bottom wiring is carried out in the basement of a private house. Hot water passes through radiators, rises through the pipeline and returns to the boiler.

The risers connect the air line to an automatic valve for removing air from the system. A Mayevsky valve is additionally installed on each heating element.

Upper wiring differs in the direction of movement of the work flow (from top to bottom).

Often installed in the attic or on the second floor. The main riser (the pipe that rises from the boiler through the floor to the central expansion tank) supplies hot water to the ring section of the overhead wiring.

Two-pipe vertical heating system (with upper and lower water supply routes) requires constant balancing. Has hydraulic and temperature stability.

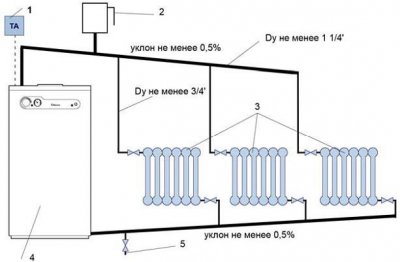

DIY installation

It is recommended to install the system in a separate specially equipped room, equipped with a boiler, expansion tank, chimney and ventilation.

Wall-mounted gas boilers do not require a chimney or a separate room. Oxygen for burning gas comes through a flexible corrugated pipe.

At the design stage, choose heating type and blowing type. To avoid freezing of the system, increase the power of the pumps and use high-quality antifreeze.

The viscosity, expansion coefficient and heat capacity of antifreeze slow down the heat exchange process and reduce the heat output of radiators.

To choose the optimal location for installation, consider the perimeter of the heated space and the location of the windows. A radiator installed near the front door will prevent cold air from the street from entering the house.

Shut-off valve in the heating system oprovides the ability to disconnect a section of the network or equipment for prevention, repair or replacement. Ball valves are installed on risers together with pumps, collectors and boilers. At the end of the work, safety and control valves are installed.

Forced circulation design

Forced circulation system requires the installation of an additional pump inside the heat generator. In some boilers with a similar system, the water circulates twenty times faster, than evaporates, which promotes faster vaporization.

Operating principle

The main factors in designing such systems are: flow rate and noise level.

Air ducts and ventilation systems are installed to increase the temperature by evaporating excess moisture.

For a permanent heating system, ceiling ventilation is used to maintain a constant temperature in the room.

Divorce

The type of wiring is similar to the system with natural circulation, but in this case it is installed additional element in the form of an electromechanical circulator. For the installation of a forced circulation system, horizontal wiring is often used, but in some cases vertical wiring is also used (example: “basement-attic”).

DIY installation

During installation, it is important to install the components correctly. Running the pump in the opposite direction will significantly increase the service life of the device. For installation of a system with forced circulation use pipes with a minimum diameter - this will allow you to save on pipeline installation and simplify the selection of an expansion tank.

It is recommended to use heating boilers, whose design provides for automation. These devices provide control and adjustment of all processes with minimal human intervention in the operation of the equipment, which allows the temperature inside the room to be regulated taking into account various factors.

Heating with bottled gas

Heating with bottled gas is less common and is used in certain regions. The system includes wall and floor stoves, which are characterized by the absence of air ducts and relatively low heat output. Effective for heating one small roomIf heating of several rooms is required, the doors between them are left open or an alternative heating system is used.

Photo 4. Heating a private house using bottled gas. It is less efficient than other heating systems.

Operating principle

The first step is to install gas to the boiler, which in turn heats the water in the pipes. To prevent the temperature in the room from dropping, It is recommended to use several cylinders at once. For this purpose, a gas ramp is used, connecting the cylinders into one system. This will allow replacing empty cylinders without interrupting the heating process.

DIY installation

Installation of balloon heating is produced by installing one or more cylinders to the generator, which is connected to the electrical panel.

To start using the system, buy a burner designed to work with liquefied gas cylinders. There are many options, but it is better to choose a burner with a power of about 10-20 kW. The cylinder is connected to the purchased burner using a special reducer. Before the first use, adjust the valve on the cylinder for uniform gas supply, since the pressure in the pipeline is much lower. Each burner comes with detailed instructions describing the purchased model.

Useful video

Watch the video, which tells how to assemble a heating system in a private house with your own hands.

Final thoughts

Manufacturers of heating equipment are constantly finding new ways to heat private homes. Choosing a system, heat generator and type of wiring depends not only on the price, but also on the calculation dataThe slightest deviation may cause a mismatch, which will lead either to the system not working or to the complete replacement of some of its elements.

Comments