And let the cold weather pass you by! Steam heating in a private house: what is it, principles of operation

Steam heating is a closed system designed for heating rooms.

It consists of interconnected components: heating boiler, steam supply pipes and heating devices (radiators).

Content

The principle of operation of steam heating in a private house or in the country

The room is heated by steam, which gradually circulates through the system due to natural or forced circulation. transfers heat through pipes to heating devicesAs it moves, the steam cools and the resulting condensate returns to the heating boiler through the “return” pipe.

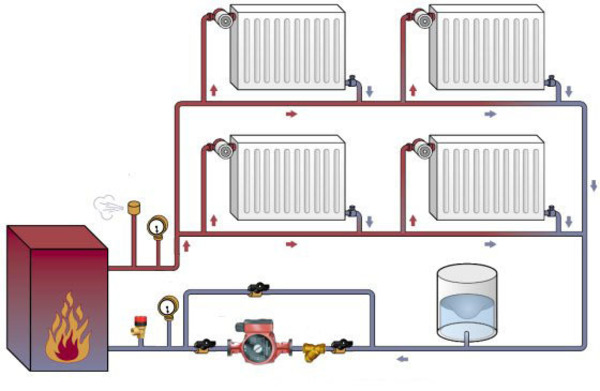

Photo 1. Steam heating diagram. The movement of hot steam is shown in red, and the resulting condensate is shown in blue.

The main advantages of steam heating:

- economic benefit;

- high heat capacity;

- operational safety.

The main disadvantages of steam heating:

- labor-intensive installation and operation (for some types of systems);

- the need to constantly monitor the operation of the heat generator;

- Installation of a heating system is only possible when building a house or undergoing major renovations.

Basic errors when assembling a system

When installing a steam heating system, mistakes are sometimes made that lead to the installation inefficient or unsafe heating system.

Incorrect selection of heating boiler power

Choosing a low-power boiler will not allow you to heat the premises to a comfortable temperature.

A device with an overestimated power due to a number of technological features will lead to a significant reducing the service life of the system.

Hasty, ill-considered choice of heating system design

The desire to save on the installation of a heating system often leads to the simplest and least expensive option being chosen. The result of such “savings” is often the installation of a model that is technically unable to heat all rooms in the house to the desired levels.

Important! It is better to choose a heating system model after a conversation with specialists.

Incorrect choice of smoke removal system

Very often, customers and installers install a smoke exhaust system without taking into account the wind rose in a specific region, therefore:

- smoke turns out to be the end result in the customer's house or in a neighbor's house;

- on the facade (roof) of the customer's house or the neighbor's house will be condensation settles (with subsequent freezing) and soot.

Types of heating systems

Steam heating systems are divided according to their characteristics into closed and open, single-pipe and double-pipe.

Open and closed

Open steam heating system differs from the closed one in its operating principle.

In an open system Water circulation occurs due to natural thermodynamic processes: water heated in a heating boiler creates “pressure” that directs hot water through the system.

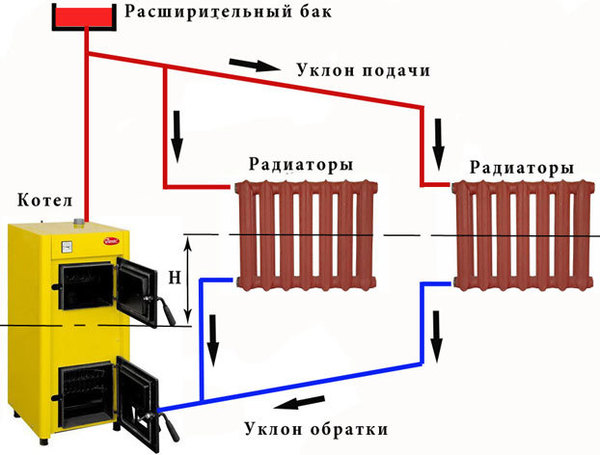

Photo 2. Scheme of an open steam heating system. Here, liquid and steam move due to natural processes.

Having reached the highest point, the water enters an open expansion tank, which is usually installed in the attic, cools down and returns to the heating boiler through the return line.

In a closed system forced circulation of water occurs. Water heated in a hermetically sealed heating tank moves through the system with the help of a circulation pump under a given pressure, eventually ending up in an expansion tank consisting of from 2 halves rolled together: Water enters one half, and the other contains nitrogen pumped in by the manufacturer, which is intended to cool the water entering the expansion tank.

The differences in the operating principle are reflected in open and closed heating system diagrams:

In an open system the heating boiler is installed at the lowest point of the system, then the water is "delivered" through thick pipes with a minimum number of turns and connections to the radiators in the heated rooms and to the expansion tank, after which it returns to the boiler through the return pipes. Taking into account the natural process of water evaporation from the open tank of the boiler, the installation location of the boiler is tied to the source of possible replenishment of evaporated water.

In a closed system In addition to the heating boiler, pipes supplying water to the radiators, expansion tank, return drain pipe, there is also a circulation pump, which creates water pressure in the system. But unlike an open system, the location of the heating boiler and expansion tank is not of fundamental importance.

The main thing is this sequence of cyclical movement of water.

Considering that water is supplied under constant pressure, pipes of relatively small diameter with any number of bends and connections are used.

Everyone makes their own choice of system, but experts recommend installing an open system. only in small one-story premises (mainly in summer cottages). But in spacious and multi-storey buildings it is better to look at the option of installing a closed-type heating system.

One-pipe and two-pipe wiring, how they work

According to the type of wiring, heating systems are divided into: single and double pipe.

Operating principle

In a one-pipe system, steam from the heating boiler rises to the highest point of the heating system through the main pipe, and then passes sequentially downwards through all the elements (radiators) of the system.

In the two-pipe version, the coolant circulates through two main lines:

- through one pipe, steam from the boiler is supplied to the radiators;

- Through another pipe the condensate returns to the boiler.

Wiring diagrams

At vertical In the diagram, the main riser(s) is(are) installed vertically, and when horizontal — horizontally.

With a two-pipe layout, it becomes possible to connect at one level of one main riser at once several "semi-autonomous" subnetworks.

Steam heating boilers: gas, electric, wood and others

One of the main components of a steam heating system is a heating boiler. The boiler is selected sufficiently power and taking into account personal financial capabilities.

Power calculation

Exists simple option for calculating power any type of heating boiler for a private home:

- In case of purchasing a boiler for both heating and hot water supply, the average value is taken 0.138 kW/m2 near a room with ceiling height 2.5-2.7 m and multiplied by the total area of the premises in the house.

- For rooms with higher ceilings 2.7 m a "ceiling height" coefficient is used, equal to the ceiling height ÷ 2.7.

- Then a “regional” coefficient is applied, which takes into account the peculiarities of climatic conditions in a particular region.

Coefficients for regions of Russia:

- southern regions - 0.85;

- the middle zone up to the Urals - 1,1;

- the latitude of Moscow to the Urals is 1.3;

- Siberia - 1.5;

- northern regions - 2.0.

- The final value is rounded up to the nearest whole number (for example, 8.3 and 8.9 are rounded to 9).

Example of calculations taking into account the coefficients:

House in the Krasnodar area with an area of 130 m2 and ceiling height 2.7 - 0.138 kW/m2 (average value) × 130 m2 (house area) × 0.85 ("regional" coefficient).

Fuel for boilers

Depending on the type of fuel, steam boilers are divided into:

- for electric ones (connected to the power grid or powered by a generator);

- for gas (connected to the gas network or powered by a gas cylinder);

- for solid fuel (mainly run on wood or coal);

- liquid fuel (run on diesel fuel, gasoline or used engine oil);

- pellet (work on wood granules - pellets);

- for combined boilers (boilers that can operate on two types of fuel).

For electric boilers are characterized by simplicity and a high degree of safety during operation, and are environmentally friendly. However, direct dependence on the power grid is fraught with consequences - any accident on the line will lead to the house being left without heating.

A slightly more economical option is to install a system liquid fuel boilers.

Tsolid fuel heating boilers even cheaper to operate, but labor-intensive to maintain: ash removal and new fuel loading are performed every 6-8 hours.

Pellet boilers — is a relatively expensive novelty that is rapidly gaining popularity among cottage owners. Thanks to the use of modern technologies, the use of wood pellets is environmentally friendly and economical, and the operation of the heating boiler is maximally automated.

Gas boiler — the most economical and common type of boilers. Despite the fact that its installation is carried out only after obtaining a special permit and during operation it is necessary to strictly observe fire safety measures, gas boilers are easy to use and quite reliable.

Heat exchanger material

Steel — the most common material for making heat exchangers in inexpensive boilers.

It is an inexpensive, easy-to-process material. However, It also has some serious disadvantages:

- Elasticity causes the surface of mild steel to crack when exposed to high temperatures for long periods of time.

- Steel is subject to corrosion.

But as for durability and reliability cast iron heat exchangers no questions: cast iron is almost not subject to corrosion. However, when using cast iron heat exchangers, uneven heating and the entry of very cool water from the return line into the boiler must not be allowed.

As for electric boilers, here the water is heated by an “electrode”, which is found in inexpensive devices graphite or steel (stainless steel), and in expensive (elite) models - titanium.

Features of wood-fired devices, their efficiency

Work efficiency "wood" boilers depends on:

- From use only low-ash hardwood firewood (ideally oak or beech).

- From the position thermostat flaps: the closed damper leads to a significant reduction in boiler efficiency.

Attention! Heat exchanger temperature drop up to 55 °C leads to accumulation of wet ash. Accumulated ash clogs the heat exchanger, and gases begin to penetrate into the room. carbon monoxideIn addition, corrosion processes caused by condensate significantly reduce the service life of the boiler.

- From availability small mixing circuit return water, which protects the heat exchanger surface from low-temperature corrosion and facilitates easier separation of condensate and resin.

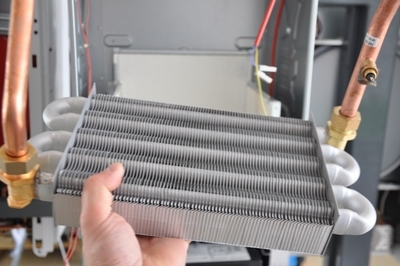

Photo 3. Wood boiler for steam heating. Quite often used in such a heating system.

Useful video

Watch a video that talks about the one-pipe type of heating systems.

A few words in conclusion

Regardless of the type of steam boiler, it is better to install it in a separate, well-ventilated room with a chimney.

This will not only protect other rooms from contamination with soot and smoke, but will also help to eliminate direct contact between small children and people with mental disorders and the boiler.

It is strictly forbidden to use it technically faulty boiler and hot water heating system.

Only full compliance with all operating and safety regulations will ensure maximum long-term and efficient operation of the system steam (water) heating.

Comments

Our batteries are metal-plastic, with them the whole system works properly, warming up the room well. The pump evenly spends heat, and accordingly energy.