The efficiency of the boiler is incredibly high! What other features does solid fuel heating have?

Why heating is called solid fuel is clear from its name - solid fuel acts as an energy carrier in it, which, in turn, can be renewable (wood) and fossil (peat, coal, shale).

Types of solid fuel

Popular types of solid fuel for heating a home or for use in boiler rooms are considered:

- coal fuel - hard coal, anthracite, brown coal;

- peat fuel - peat briquettes or pellets;

- oil shale;

- wood fuel and its derivatives.

To decide which raw material is best to choose for heating a specific facility, take into account boiler characteristics (consumption of various types of fuel), prices for energy sources and their delivery in the region.

For heating a relatively small building, the most acceptable environmentally friendly fuel is wood and its derivatives: sawdust, shavings, chips, briquettes and pellets. Wood fuel is somewhat inferior to coal in terms of calorific value, but the advantages of firewood are undeniable:

- Availability in most regions of Russia, and accordingly the price is low.

- Eco-friendliness - firewood does not emit harmful substances (sulfur) into the atmosphere.

Coal beats wood due to longer burning time.

Types of solid fuel boilers for heating

The task of heating equipment of any type consists of heating the coolant: water, antifreeze, oil or special liquid to the specified temperature.

Therefore, all types and models of solid fuel boilers have a number of common characteristics.

All boilers of this type have one common drawback. - the need to constantly add fuel throughout the heating season. It is impossible to eliminate this drawback, but it is quite possible to increase the frequency of adding firewood, coal, and peat by including additional units in the boiler design. To implement this, you need to clearly understand the operating principle and mechanism of a solid fuel boiler.

In total, there are different three types of solid fuel boilers — classic, pyrolysis and pellet devices.

Classical scheme

Traditional, standard model of solid fuel boiler is capable of operating normally on any solid fuel.

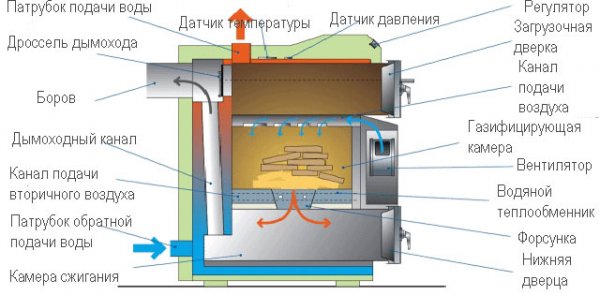

The operating principle, like other types of boilers, is based on the combustion of the "offered" raw material in order to heat the coolant to a specified temperature, with the heat released during the combustion process. Classic boiler works in the same way as a conventional oven, but the walls and "roof" of the firebox are a water jacket. The boiler's fuel chamber itself is voluminous, separated from the ash pan by grates at the bottom. The air needed for burning the raw material enters the firebox through the ash pan door with a damper and the grate.

Photo 1. The structure of a solid fuel boiler of the classic type. The arrows indicate the parts of the device.

The flue gases formed in the boiler firebox are removed through the chimney, and along with them also A significant portion of the heat "goes down the drain". This point should also be taken into account when choosing a device model. Many manufacturers use additional smoke corridors and bends in the designs of their boilers to increase efficiency.

The obvious advantage of a classic heating device - absence of electronics, automation, various types of control systems, which are very "fond" of breaking down. If the boiler design has a thermostat, it works on a mechanical principle.

Such arguments speak about the reliability of the classic solid fuel boiler. As for the disadvantages of the design of the boiler of this type, there is only one - the equipment requires constant attention throughout the heating season: fuel supply, ash removal, cleaning of walls and chimneys.

Pellet heating devices

Pellets are small cylindrical granules made from wood, peat and agricultural waste. This biofuel has a heating capacity one and a half times greater than that of firewood. 20% humidity.

An automated installation with high efficiency has been developed specifically to reveal the potential of pellets (92%). Pellet boiler can go unnoticed for quite a long time human.

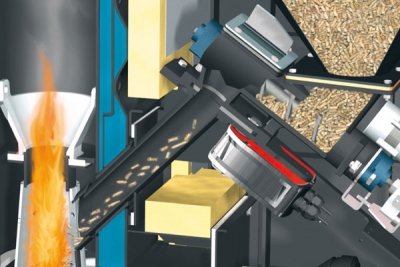

Photo 2. Pellet solid fuel boiler. On the left is a funnel-shaped tank for loading pellets.

The continuous burning time of the boiler depends on two conditions:

- Bunker capacity with a supply of pellets, from where they enter the firebox.

- The need to clean the device parts from soot and ash.

The main elements of the boiler are combustion chamber (firebox) and tubular heat exchanger. The main unit is a burner with forced air supply. The hot air produced by the furnace, passing through the fire pipes, transfers heat to the water jacket, and through the chimney, already cooled, is thrown out. In high-power boiler models, a fan - a smoke exhauster is installed for such work.

Pellet heat generators also have a manual fuel loading scheme. In this design, the boiler differs from classic models only by a special torch burner that provides a continuous flame. It has an attached small-capacity hopper with a fuel reserve. for 1 - 7 days of continuous burning.

Specific gravity of pellets from 600 to 700 kg/m3, and the average daily fuel consumption is 2 kg per hour for a device with power 10 kW, i.e. 48 kg per day.

The benefits of using a pellet boiler include the following features:

- Increased heat transfer of fuel and the boiler design itself allow achieving efficiency up to 92%.

- Automation ensures ease of maintenance and operational safety.

- High continuous burning time.

- Minimum amount of harmful emissions into the atmosphere.

The disadvantages of pellet boilers include:

- Energy dependence.

- High cost - the most expensive among their "brothers".

Pyrolysis

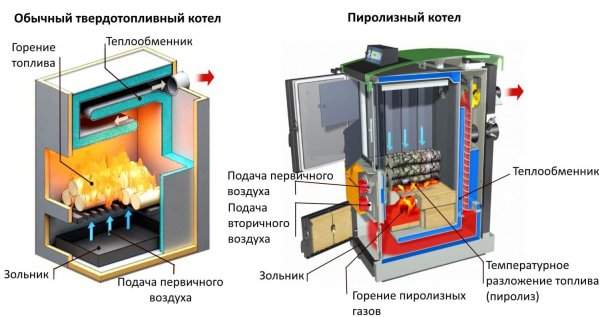

From traditional boilers to pyrolysis boilers are distinguished by a double combustion cycleOne of the chambers is used for burning fuel, the other for the released gas.

The raw material in the first chamber of the boiler burns at a low oxygen level and high temperature (up to 800 °C) and starts the process of formation of pyrolysis gas, the amount of which depends on the humidity of the fuel.

The best energy source for such a device is hardwood. It is permissible to add pellets, as well as wood waste (no more than a quarter of the volume of firewood).

Scheme of operation of the gas generator:

- Fuel is placed on the grate.

- Primary air supply is provided.

- The ignited fuel is brought to the required temperature.

- By adjusting the valve, the air supply is limited, thereby starting the pyrolysis process.

- The resulting gas is pumped into the secondary chamber simultaneously with the air supply.

- The gas, when in contact with oxygen, burns with a large release of heat, thereby heating the liquid in the heat exchanger.

- The combustion product, smoke, exits through the chimney.

Photo 3. Comparison of the structure of a solid fuel boiler of the classic type (left) and a pyrolysis boiler (right).

The rate of reaction of gas with oxygen regulated by an automatic valve, which allows maintaining the required temperature of the coolant.

The advantages of gas generator boilers include:

- complete, almost 100% fuel combustion (efficiency) 85 - 95%);

- easy regulation of coolant temperature.

The disadvantages of boilers are considered to be:

- high cost of equipment;

- high demands on fuel quality (humidity no more than 20%).

Attention! The temperature in the return line should be not less than 50°If this regime is not observed, condensation will form, leading to corrosion of steel elements.

Materials for making a boiler

Once the issue with the type of fuel has been resolved, they begin to select the material for the main element of the heating system - the boiler.

- Cast iron

Its advantages include durability, a cast iron boiler serves 35 years and olderBut this is where the positive qualities end.

The negative characteristics of a cast iron boiler include: high risk of thermal shock.

Fragile According to its physical properties, cast iron is an alloy of iron and carbon, reacts poorly to sudden temperature changes. Due to this quality of the material, the boiler requires piping, i.e. connection of one or more heating circuits, equipping the heating system with automation.

Price - an important point that deserves attention, because the cost of a cast-iron boiler is high, and if repairs are necessary, you will have to pay a considerable amount. This is explained by the impossibility of repair - cast-iron elements in boilers cannot be welded or sealed effectively. A defective part will have to be replaced completely.

Cast iron afraid of sudden mechanical impact (shock).

Experts and users have not come to a consensus on this issue. long cooling of the cast iron elements of the boiler. In terms of operation, this is good, but in case of urgent repairs or the need to quickly switch to another heating mode, it is bad.

- Steel

This is the same alloy of iron and carbon. But unlike cast iron, it contains other chemical elements - metals and non-metals. Given this fact, steel is considered an alloy containing not less than 45% iron.

Important! Cast iron boiler, with automatic control, is worth it 2 - 2.5 times more expensive than steel, and is used primarily for heating schools, hospitals, and small industrial facilities.

Steel boilers are subject to corrosion and serve 10 - 15 years less than cast iron, but alsohave some advantages:

- The equipment is cheaper than the previous option.

- A low-power steel boiler can have a firebox of quite a large volume. For cast iron devices, the firebox depth depends on their power, for example, 15 kW corresponds 30 centimeters. Whereas with steel boilers - with similar power, the depth can be up to 60 cm.

- Steel boilers can be repaired and can easily be brought into working condition by welding.

- Almost all devices are equipped with automation, which cannot be said about cast iron products.

Useful video

Watch the video, which demonstrates the process of installing a solid fuel boiler in a house.

How to choose the power of the device

To make a final choice of a heating boiler, You need to know the heat transfer of the fuel and the procedure for calculating the required power.

Heat dissipation:

- coal - 6500 kcal/kg;

- wood waste briquettes - 4500 kcal/kg;

- firewood 20% humidity - 3600 kcal/kg;

- firewood 50% humidity - 1900 kcal/kg.

Coal has the highest heat output, but the use of wood is advisable at a low price in the region of residence.

Retailers offer a wide range of heating equipment, but not all manufacturers are in a hurry to indicate the primary fuel in the characteristics of the devices.

If the boiler is designed for coal, wood will also burn perfectly in it, but the efficiency will not correspond to the declared one. This will affect on the duration of combustion and the amount of wood consumed.

Make the right decision for the user simple arithmetic calculation will help.

On average for heating 10 m2 rooms height up to 3 meters required 1 kW boiler capacity. That is, to heat a space with an area 100 m2 enough 10 kW.

A similar result will be obtained if the calculation is made based on the volume of the room. In this case, with effective thermal insulation of the building, it is necessary 40 W per 1 sq. m. For example: the height of the walls 2.5 m, square 100 m2, 100x2.5x40=10000 W (10 kW).

This calculation is appropriate when the boiler is used only for heating. For a double-circuit boiler, which serves as an indirect heating boiler, take into account heat exchanger capacity.

Comments

It is better to take a cast iron boiler rather than a steel one.