Every home needs a hot “heart”: how to choose and install a metal wood-burning stove

Small Cast iron and steel stoves are installed in temporary buildings, summer cottages, and small rural houses. Big ones Metal heating devices of modern design are placed in spacious residential buildings and cottages.

Homemade iron stoves are distinguished by their simplicity, but some craftsmen are able to turn their own devices into real works of art.

Content

How to choose a home metal stove?

Enterprises create tens iron stoves, which differ in size, firebox volume, design, appearance and operating modes. When choosing a metal heating device, consider a number of factors:

- region accommodation;

- house area, number of heated rooms;

- frequency of use stoves;

- design interior and preferences the owner of the house.

In regions where sub-zero temperatures last up to 5-6 months in the year, the requirements for heating devices are increasing, homeowners give preference brick structures. But if in winter the temperature rarely drops below 10 degrees, home heating metal The device is quite suitable for heating a home.

If the owners live in the house permanently, the metal stove must support comfortable temperature for several hours after burning one portion of fuel.

Area of the dwelling and number of heated rooms also influences the choice of device. If the house consists of spacious rooms, choose a large, long-burning stove with good heat output. For small houses with only a kitchen and a couple of rooms, a medium-power unit is enough. If the owners only come to the house from time to time, you can install a small stove that quickly gives off heat.

The choice of device is also influenced by the tastes of the owners of the house. There are iron stoves for sale, designed in the styles of high-tech, baroque, Provence.

Photo 1. A very unusual metal stove, designed in the form of a ladle from a Cat tractor.

Specific examples of choice

The choice of a metal stove begins with determining places of its installation. The heating unit is placed near a wall protected by heat-resistant material. Some owners place the device right in the middle of a large kitchen or room.

The wall where the stove is located gets hot, so it protected with heat-resistant material. The screen is made of brick, ceramic tiles, bars and tiles made of natural stone. The thickness of the screen depends on the degree of heating of the wall.

For a wooden house

For a wooden house, wood-burning stoves are often chosen. To heat a wooden structure, you don’t need as much heat as a brick or concrete cottage. Let’s consider the choice heating and cooking stove for a small log house area up to 50 square meters.

There are hundreds of models of metal stoves on sale from dozens of Russian and foreign factories. Have proven themselves well heating and cooking appliances foreign manufacturers:

- Konig Feuer;

- Trend;

- Olympus;

- Magnum;

- Thorma;

- Alma Mons;

- Efel;

- Ferlux.

The stoves are installed made of steel and cast iron, have different designs and constructions.

The fireboxes are made of cast iron, and all models have firebox walls fireclay, vermiculite or other fire-resistant liningThe vermiculite lining of the firebox allows it to be heated up to 1200 degrees, fireclay - up to 1300 degreesFood is prepared on the hob and in the oven.

There are dozens of reliable and high-quality ovens on sale from Russian manufacturers such as “Termofor”, “Ligov”, “Teplodar”, “Ermak”. The devices have a steel body and channel fireboxes, which allows you to regulate the temperature and firewood consumption. In many stoves, in addition to the cooking deck, an oven is installed.

In all devices There is an ash pan section covered with a grate, throttles for regulating the air supply. The doors are solid or with a window made of fire-resistant glass.

For a country house

For a country house and a summer cottage, they often choose compact stovesThese structures allow you to quickly heat small rooms and maintain an acceptable temperature for 2-3 hoursIf there are no problems with electricity in the village, it is enough to purchase a stove designed only for heating the room.

Photo 2. The Buleryan stove. Hot air passes through curved tubes and the heat is retained longer.

There are compact heating and cooking devices on sale. If the unit is needed exclusively for heating, small stoves of the models “Buleryan”, “Cinderella”, “Vesuvius”, “Student”, “Engineer”.

Reference. Companies usually produce dozens of furnaces with the same name, but with different digital codeAmong them are cooking and cooking-heating devices.

Schemes of iron wood-burning stoves

There are chamber, channel, pyrolysis and long-burning fuel stoves. They differ in heat transfer, gas circulation, combustion modes, type of fuel.

Chamber design

It consists of a steel or cast iron body, which contains one combustion chamberFor loading firewood, the body has a hatch with a door.

At the bottom A grate grate is installed in the furnace, under it there is an ash pan (blower) and a door for removing ash. At the top A round or square hole for the chimney is cut out of the casing (on top or on the side).

Channel device

The stove consists of a steel or cast iron body, which contains a firebox, a grate, a ash pit with a door. Inside the firebox are located horizontal partitions-channels (from 1 to 3), forming an afterburning chamber. Air enters it through gaps in the burners or through a regulator (throttle). The chamber creates an obstacle to the direct discharge of gases into the pipe, air and gases circulate inside the chamber, are burned and give off heat.

Reference. Most iron heating and cooking devices are ducted.

The furnace gases are discharged into the chimney through a horizontal pipe. Depending on the throttle adjustment, the stove operates in two modes: long and fiery combustion.

Long burning stoves

Such devices give off heat up to 6-10 hoursAfter the wood has caught fire, the chamber is filled with fuel. by two thirds and restrict the air flow. Smoldering occurs in the upper layer of fuel, for complete decomposition of the wood, air is supplied through the regulator. The regulator is located in the upper or middle part of the furnace body. Complete combustion occurs under the arch.

Photo 3. Three models of long-burning stoves from the manufacturer "Termofor". The design is the same, only the color of the coating differs.

Making an Iron Home Stove with Your Own Hands

When making a home iron stove, it is of great importance selection of materials. It is better to take as an example proven scheme heating device. Let's consider the process of making a small channel heating and cooking stove for a country house.

Selection of materials

Home craftsmen often use as a material cast ironCast iron plates are well welded using arc welding, this metal is durable and reliable, heats up quickly and withstands overheating.

Important! Cast iron can't stand it sudden temperature changes and cracks from splashes cold water.

If the stove does not overheat to red heat, it will be suitable for the body regular steel 8mm thick. This metal will last a long time if it is not subjected to frequent heating to temperatures above 600 degrees.

Factory furnaces with a steel body thickness of up to 1.5-3 mm are made from heat-resistant steel, which is cooked using a complex technology, unavailable at home.

When arc welding, heat-resistant steel becomes brittle. The problem can be solved by joining the parts with rivets.

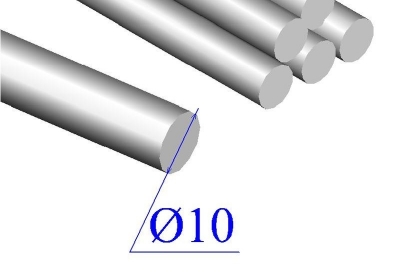

To make the door fastenings, latch and handle, you can use steel rod with a diameter of 8-10 mm and sheet steel with a thickness of 3 mm.

Preparation of tools and equipment

For work you will need welding machine, electrodes, plasma cutter, hammer, angle grinder with a set of disks, metal pencil, metal tape measure and ruler, piece of chalk. Work is carried out on a table made of non-flammable material or on steel trestles.

Place for building a home stove

The choice of an iron stove is often limited by its weight, since the construction foundation — a long and expensive process. Without a foundation, only a small device can be installed on a wooden floor.

A sheet of flat slate, asbestos cardboard, ceramic tiles, a layer of brick, or other material is placed on the floor. fireproof material.

Iron stoves weighing 300-400 and more kilograms are set only on a foundation that is not connected to the floor boards and joists.

The most reliable and durable option — a solid foundation made of concrete reinforced with a steel lattice. A layer of ceramic bricks is laid on the concrete using clay-sand mortar or slabs of natural stone.

Important! It is allowed to install a metal stove only on a level surfaceThe correctness of its placement is checked using a building level.

Step-by-step instructions for making

Before starting work, prepare materials, equipment, a work table or trestles. The process of creating a furnace consists of from the following stages:

- A steel sheet is placed on the table (or on the floor) and the markup with a steel pencil.

- The parts are signed with chalk indicating the dimensions.

- Details cut out plasma cutter.

- In detail, a round shape is cut out hole for the pipe and hole-burner.

- On the plate that will be welded to the front of the device, cut out portal for firebox door and ash pit door.

- A hole is drilled in the plate separating the ash pit grate holes.

- Details weld together according to the project. Plates forming channels and a grate plate are welded inside the furnace.

- To the hole for chimney weld a piece of steel pipe.

- Welded to the bottom of the oven racks, made of steel angle section.

- The furnace portal is welded hinge holders firebox door and ash pit door, latches and handles.

- They put the doors on on the hinges.

- Surface of the device cleaned from scale, metal splashes, ground and polished.

- In progress final finishing stove surface: hot or cold bluing, painting with heat-resistant enamel.

Possible problems and difficulties

For amateur craftsmen, the problem often becomes welding qualityIn this case, you should seek help from professionals.

The complexity is also weight calculation stoves. If the structure is heavy, you will have to take care of building a foundation.

For stove owners, an unexpected problem is ceiling heatingIn this case, a layer of material with low thermal conductivity is attached to it.

Useful video

A video that demonstrates in fast motion the entire process of making a long-burning stove: from an empty pipe to the finished product.

How to Properly Use a Metal Stove for Heating

In front of the firebox door, they are fastened with screws steel sheet, under which it is placed a layer of asbestos, or ceramic tiles. The tiles are laid on heat resistant glue, leaving no gaps.

To prevent carbon monoxide from entering your home, the valves are never completely closed until the end of the combustion process. Cannot be used for kindling gasoline, acetone, diesel fuel, alcohol-containing liquids, since when they ignite, the fire spreads to the room. In factory furnaces, only those materials specified by the manufacturer are used as fuel.

Comments