And the heat will not go anywhere! Choosing a heat exchanger for a sauna stove

A heat exchanger is a special device. to transfer thermal energy from a heat source, usually a stove or a boiler, liquid coolant.

The coolant in the heat exchanger is water, as well as any other liquidAfter heating, the unit is used for domestic, industrial or other needs.

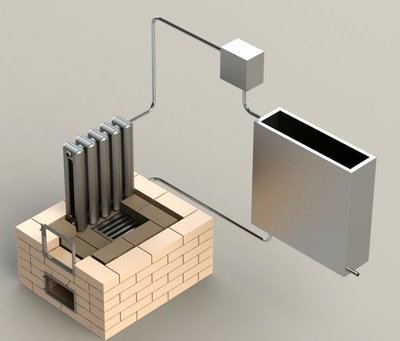

Heat exchanger device for a wood-burning sauna stove

High heat output of sauna stoves, increased intensity of combustion of fuel in them are actively used for placement in them devices for heating water for washing.

Heat exchangers for baths are a hollow, sealed container for water, having the form of a serpentine (register), placed in the firebox, as well as sealed tank, placed on its wall or chimney.

Water heating device circulation type are connected by a pipeline system to a hot water storage tank.

Operating principle of indirect water heating devices based on fluid circulation as a result of its natural convection.

Reference. Natural convection of liquid occurs when the lower layers of liquid heat up and become lighter, rising to the top, while the heavy and cold ones descend, taking the place of the heated ones.

For operation of an open liquid recirculation system (without using a circulation pump), the diameter of the pipes delivering water to the storage tank, should not exceed one inchto ensure the required circulation rate.

Length of pipes from heat exchanger to storage tank should not exceed 3 meters. This length is often enough to move the storage tank from the steam room to an adjacent room for washing.

The capacity of hot water, according to the laws of natural convection, is set above the heat exchanger level.

Threaded pipes are welded to the water heating equipment on the inlet and outlet sides to connect the circulation pipes that connect the device to the tank.

The most commonly used storage steel tank volume 60-120 liters, depending on the power of the oven.

A drain tap for washing is installed on the storage tank, and a tap for draining liquid from the system is installed on the cold water circulation pipe (lower).

Important! Specialists not recommended install a circulation pump in the water heating systems of sauna stoves.

Types

The following types of devices are commonly used:

- Interior. The simplest option, manufactured in the form of a coil built into the furnace firebox, directed towards the active use of the heat generated by the fuel.

- External. It is a water tank mounted on the outer side wall of the furnace. The high temperature of the wall heats the tank by transmitting thermal radiation to it. This option is easier to manufacture than an internal heat exchanger.

- Outer. A water tank installed on the chimney pipe is an effective way to install a heat exchanger, which does not require much effort in its installation and does not take up much space in the steam room.

- External flow-through (economizer). It is a small flow heater of medium capacity. from 5 to 10 l, installed on the chimney pipe and connected to the storage tank by a system of pipelines. This is probably the best heat exchanger in terms of its installation and use.

Photo 1. External heat exchanger for a sauna stove. The device is made of stainless steel and is placed on the chimney.

- Combined models. At the same time, the design includes a coil built into the firebox and an external water tank installed on the chimney pipe. Both devices are connected by a pipeline system and have a separate connected tank for collecting hot liquid.

What are they made of?

Internal heat exchangers (registers) in the form of an L-shaped grid are made of bent steel, cast iron or copper smooth-walled pipes diameter 40-50 mm.

Water tanks are made from cut and welded sheet steel with a thickness exceeding 2.5 mm.

The most popular material for making water heating devices is stainless steel, because it is an inexpensive metal with high heat resistance.

Attention! In the manufacture of heating devices of this type undesirable use galvanized steel, because at temperature above 200 degrees Celsius zinc begins to evaporate.

Disadvantages of cast iron units - their fragility and weight, and copper - high price and insufficient heat resistance.

Location: on the chimney, inside the firebox, on the side wall

Internal structures are located inside the furnace firebox along its contour in such a way that they are not in the zone of maximum flame temperature and hot gases leaving it, so that the device lasts as long as possible.

External units heating elements are installed on the side wall of the stove so that they do not interfere with the use of the stove.

External, including flow-through (economizers), installed directly on the chimney pipe, encircling it in a circle.

Recommendations for selection

Advantages and disadvantages of the options heat exchangers:

- Interior. Directly contacts the combustion zone, so the heating rate of the coolant is high. However, the efficiency of fuel combustion in such a system is low, since the coolant takes away part of the energy generated from the fuel, which leads to its overconsumption when heating the steam room. According to calculations, the efficiency of internal heat exchangers does not exceed 50%.

- External. It heats up slower than a coil due to its distance from the heat source, however, it also takes heat away from the firebox wall, reducing the efficiency of the system. Disadvantages of the scheme - a tank placed on the wall of the stove requires constant addition of cold water due to its rapid heating, as well as a possible risk of burns when touching the tank.

- Outer. Increases the efficiency of fuel combustion in the furnace up to 60% by cooling the hot gases passing through the chimney, which reduces the time it takes to heat up the steam room and the amount of fuel required. The disadvantage of the external option is the need to add cold water when it boils in the tank.

- External flow-through (economizer). When using an economizer, the water in the tank has time to warm up to the temperature required for washing while the steam room is heating up, which makes this system the best option for use in baths.

Important! When manufacturing a heat exchanger and storage tank, it is better to choose the shape and size by comparing them. with furnaces of similar power from well-known manufacturers, as these stoves have passed the required efficiency tests.

Combined models include the disadvantages of the listed options and are not very popular today.

Types of devices in pictures

Photo 2. External heat exchanger installed on the pipe of a sauna stove. The device is filled with water.

Photo 3. External flow heat exchanger for the furnace, made of copper. The device is put on the chimney.

Photo 4. External flow heat exchanger for a sauna stove. The device is connected to the water tank using pipes.

Useful video

Watch the video, which demonstrates the process of installing a heat exchanger for a sauna stove, made by yourself.

Fuel for sauna heat exchangers: wood, gas, combined

Today, the market offers sauna stoves with direct and indirect water heating devices. all of the above structures.

These include inexpensive wood-burning stoves, powerful cast iron stoves, and stoves that run on gas or combined fuels.

When choosing a heat exchanger for the required fuel, experts advise paying attention only to the fact that it is made made of high-quality stainless steel, which will extend its service life and make using the bathhouse convenient and safe.

Comments