For those who like to swim even in cold weather: a wood-burning stove for a pool. How to build it yourself?

For those who love water treatments cold season you involuntarily have to choose bodies of water with cool or completely icy water.

But not everyone can withstand swimming in an ice hole or an unheated font with a temperature 12–15 degrees.

Therefore, the problem of heating the water arises. Of course, it will be impossible to heat an entire lake or river. But a bath tub or a small pool it won't be difficult to heat it up.

How to Heat a Lot of Water for a Pool

In practice, heating of water in a pool is carried out using different methods:

- By using flowing method. To heat a large amount of water, its circulation is organized through a heating device. The liquid is taken from the bottom of the pool, filtered and passed through the heater. Warm water under pressure is injected down the pool from the opposite side from the intake opening.

- By using indirect heating. In this case, the water is heated by the warm walls and floor of the pool. This is how heating of stationary year-round pools is organized.

In different cases, electricity, solar energy, gas combustion, oil products and wood-burning stoves help to heat the pool.

Wood burning stove

Solid fuel stoves can handle any volume of heated water in the pool, they are easy to operate and economical.

You can choose the right stove for heating your pool by determining the task that the equipment faces:

- Heating year-round pools with a large volume of water, maintaining a constant temperature. Massive brick ovens with a heat exchanger, long-burning boilers of the type "Stropuva", pyrolysis boilers with shaft design.

The advantages of such furnaces are the possibility maintain the same temperature for a long time in the heat exchanger and regulate the heating speed, long autonomous operation time without loading, the ability to heat the pool using indirect heating. The downside is the relative high cost of the equipment, complex plumbing piping.

- Fast heating seasonal indoor pool and maintaining the required temperature. The main requirement for the equipment is high power. It can be calculated knowing the volume of the pool, the difference in water temperatures, heat loss. To heat 1 liter of water by one degree for 1 hour you need 0.001 kW. Heating 1 thousand liters in 1 hour will require power in 1 kW.

Taking into account heat loss, this indicator must be multiplied by 1.2-1.3. So the boiler for 25 kW will heat 1 a cube of water by 1 degree in 15-20 minutes. The water heater must be installed permanently; it is better to use a flow-through heating system.

- Fast heating small street pool at low ambient temperatures. The main requirement for a boiler for this operating mode is high power and mobilityThe low weight and compactness of the stove will be a pleasant addition.

Optimal choice of material for the heater

To choose the right material for your pool heater, you need to consider the following factors:

-

Opportunity transportationDue to its heavy weight, it is better to place a brick device permanently on a good foundation.

If the pool is collapsible and installed in different places, it is better to use a metal structure.

- Availability free space. Metal boilers take up less space than brick ones; a brick structure will need to be protected from the effects of precipitation: build a roof or assemble a stove in the building.

- Cost and availability materials.

- Opportunity to attract a qualified welder or a stove-mason.

A brick boiler is durable and looks good. A brick oven can also perform a number of other functions: heat the room, cook foodIf you have the skills, you can make such a device yourself, which will significantly reduce the cost of the entire heating system.

A homemade metal structure is chosen if the budget is limited.

Boiler diagram

Various types of structures are used to heat water in the pool. The devices consist of a firebox, a heat exchanger, a body and a chimney.

Metallic the units are mobile and have high efficiency, do not require a solid foundation.

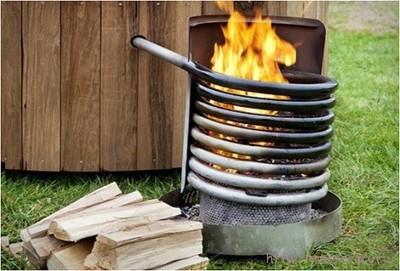

The simplest homemade device for heating water in a pool is a metal cylinder with a layer of water laid inside along the walls. Heat exchanger: stainless steel coil. Wood is burned inside, water is pumped or flows by itself into the pool located nearby.

Photo 1. To make a pool heater, you need a similar coil: this is a heat exchanger through which the coolant will circulate.

A metal stove with a built-in heat exchanger It is more difficult to make, but it is more effective. The firebox is located under the heat exchanger, which can be a mesh of welded pipes, a coil, ribs of cast-iron batteries, car radiators with sparse plates. Hot gases, passing through the heat exchanger, heat the circulating liquid.

In boilers based on a long-burning stove "Buleryan" all the fuel goes to heating the passing water. Home craftsmen have long learned to make such devices from profile pipes and sheet metal.

Building a boiler with your own hands

When working with metal, it is important to follow the simplest rules safety rules.

Selecting a project

For a home craftsman, the real challenge will be to make it yourself Buleryan type heater, however, with patience and metal welding skills, this task is feasible.

To create a device for heating water, you will need a square profile pipe with a wall thickness of 4 mmDuring the work, a welding machine, grinder, clamps and other metalworking tools are used.

In addition to the square pipe, you will need several sheets of iron for the second chamber and doors, a valve, a pipe for the expansion tank, plumbing threads for the outlet and inlet of the coolant.

The procedure for welding a hot water stove using wood

First of all, the collectors are welded: lower and upper. The lower one has the shape of a “box”, the entire structure will stand on it, the upper one is of any shape, and functions as an expansion tank.

The heat exchanger consists of L-shaped, square or curved in the form of a clamp round pipes. Their bottom is connected to the manifold, the top - to the expansion tank. The gaps between the pipes are welded tightly with sheet metal.

On 2-3 heights a secondary combustion chamber is installed in the resulting tunnel. Hot gases rise along a hot shelf. It is better to make it out of metal 5-7 mm thick, Air ducts are connected to the beginning of the shelf.

A firebox is arranged below the firebox grate.

The ends of the tunnel are welded, a chimney is mounted on the back wall, and doors and an ash pan are hung on the front side.

It is convenient to make an ash pan in the form of removable scoop: it makes it easier to clean the oven.

The legs are welded on, handles and wheels are hung on - the stove can be moved like a wheelbarrow.

The stove is ready, now you can connect the chimney, fill the system with water and do a test run.

Difficulties in manufacturing

The only difficulty in making this type of oven is tightness of welded seams. If you 4th category welder, then you can weld with any welding machine. If you are a beginner, buy a semiautomatic machine and carbon dioxide cylinders and take welding courses.

Before starting work, draw a simple sketch of the boiler with all its parts.

Attention! Violation of work technology, lack of special clothing or personal protective equipment may lead to mutilations. Use glasses, protect your hands, do not cut with a grinder while hanging, do not weld without a protective mask!

Useful video

Check out this video that shows how to build a homemade wood-fired pool heater.

Conclusion

It is not difficult to operate a pool heater correctly. However, there are several recommendations that will help prevent breakdowns and extend the service life of the equipment.

Light the stove dry firewood. The moisture that evaporates from the damp firewood in the firebox condenses in the chimney and causes corrosion of metal parts. Most stove owners dry firewood in natural conditions: under a canopy. Optimal humidity levels in 15-20% the firewood reaches beyond two years of drying.

Avoid carbon monoxide getting into the room. If the coals are still smoldering in the firebox, the chimney damper must not be closed completely.

Some parts of the stove become very hot when fired. Touching the doors or damper may cause burn.

Make sure that there is enough heat in the heat exchanger during firing. coolant, and he was constantly circulating. If the coolant boils, the system may explode. Before lighting the wood, make sure that the system is in good working order, all taps are open, and the circulation pump is energized.

Harness The furnace for heating the pool must be made made of metal. Plastic and polypropylene are not suitable: the temperature near the heating element can be high, and plastic joints may not withstand it.

The highest efficiency of the stove is achieved when burning wood in an intensive mode. Therefore, it is better to do it more often small bookmarks.

Comments