Building a ceramic kiln yourself: better than buying a factory-made one?

Having sculpted a product from clay, you need to dry it, to prevent ceramics from falling apart, kept its shape.

However, to make the clay durable and moisture resistant, it must be fired.

For this product heated to 900–1800 °C and are left for some time. The clay dries, bakes and hardens.

How to fire ceramics?

To properly fire ceramics, it is important to maintain the temperature regime in the kiln. Firing takes place in three stages:

- Evaporation of moisture. Products are heated to 250 °C and remain at this temperature.

- Incandescence up to 900 °C in a closed oven. The clay is sintered.

- Gradual cooling.

Kilns must not only develop the required temperature, but also allow it to be regulated. The design should be as simple as possible., loading and unloading of products is easy.

Types of furnaces

They differ in the types of thermal energy sources:

- The most ancient one is wood-burning oven. The masters kept the secrets of firing and passed them on only to their students. Today, firing with wood is a great rarity. Technological types have replaced it.

- The most popular is natural gas. With forced air blowing, products are easy to heat up to temperatures above 1500 °C. Gas equipment is easy to make with your own hands, and gas can be purchased in liquefied form in cylinders.

- The most high-tech is electricity. Inside the oven, electric coils are evenly laid out, quickly and accurately heating the chamber with products. Such equipment is more difficult to manufacture, high voltage requires compliance with safety precautions and electrical installation rules.

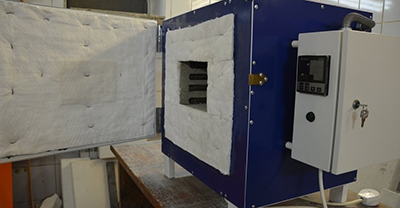

Photo 1. A small electric kiln for firing ceramics with evenly spaced spirals inside.

Wood burning: device and principle of operation

For a beginner potter, this is a great option. Does not require large material costs for manufacturing, and dry firewood is available everywhere. Wood stoves there are several types:

Earthen

A descendant of the ancient technology of roasting in a fire flame. Above a narrow pit - a firebox a clay roof is built on top, on which the products are placed. A vault of bricks or clay strips is erected around the products, with a smoke hole left at the top. The design works like this: charcoal is burned in the firebox, which produces a high temperature and does not smoke.

Hot gases without flames pass through the chamber with the products, heating them, and exit through the opening at the top. The temperature is regulated by the amount of coal and the "damper" on the chimney. After cooling, the vault of the stove is disassembled and the finished products are taken out.

Such a stove suitable for one-time work, since each time you have to lay it out again. But, despite the labor intensity, this option is the cheapest - the cost of components is zero.

Brick

They are collected from fired clay bricks and refractory fireclay. They are similar to earthen ones in their operating principle. They consist of a firebox with a grate, a chamber for products and a chimney.

Photo 2. A kiln for firing ceramics made of firebrick with a chimney and firebox outside, next to the house.

The difference is that the design is obtained reusable and more efficient. Products are placed into the chamber through a detachable wall or door; the stove can be fired with wood - the flame does not reach the products.

Reference! It is important to use dry firewood, otherwise the products will absorb moisture and become covered with cracks. Brick has high thermal conductivity, the stove cools down, so this design is characterized by gluttony.

Metal with lining

Thanks to the use of basalt and kaolin insulation the wood stove becomes more heat-resistant and efficient. Such a stove consists of a firebox on which a metal container is installed.

Photo 3. A ceramic kiln with a non-heated metal body and lining has heat-resistant properties.

The walls and the lid are insulated with non-flammable material, the metal frame sometimes does not even heat up. The heat from burning wood in the firebox rises up, heating the products, and the cooled streams of air descend and rush through the underlay into the chimney. These stoves much more economical than brick, easy to manufacture.

Minus - the need to use expensive insulation materials, plus - durability and mobility of the structure.

Gas

It has a number of advantages:

- The gas burns completely, does not contain moisture.

- Gas burners develop a high temperature.

- Temperature regulation is easy.

A gas furnace for firing ceramics is made using different technologies:

- Muffle. A muffle is a separate sealed chamber in which ceramics are heated and allows for the production of earthenware and porcelain, since the blanks do not come into contact with hot gases - combustion products.

The muffle is placed in the combustion chamber and the flames are distributed evenly over the entire area.

- Chamber. Perfect for firing regular ceramics. The items are loaded into a heat-insulated chamber through which hot gases pass. The burner is installed below and separated by a partition. The temperature is distributed evenly, and the gases, when cooled, exit through a special opening at the bottom of the chamber.

Building a ceramic kiln with your own hands

The type of furnace is selected based on the number of items to be fired. If the volume is small, we make a furnace in 250-300 liters. For larger scale work it will be necessary large furnace-forge, the size of a small room.

Tools

To build a small kiln, you will need the following tools:

- Metalworking tools - for working with metal. Welding machine, set of wrenches, files, angle grinder, drill, hammers.

- For working with fireclay bricks and ceramics - mason's hammer, trowel, diamond disc for angle grinder.

- Personal protective equipment. A respirator, glasses, gloves and thick cotton clothing are a must when working with an angle grinder and mineral wool.

Work order

The furnace consists of a body, a burner, a roof, an insulated chamber, and a lid.

Construction sequence:

- Frame. We choose a rectangular metal box if fireclay bricks are used as lining, or a metal barrel if we insulate with mineral fire-resistant wool.

In a cylindrical design, heat distribution is more uniform. We weld the legs to the body.

- We are laying down lining on the bottom of the frame, we put four ceramic insulators from power lines or fireclay bricks on edge - they will serve as pillars for the roof.

- We lining the walls and roof. It is better to lay fireclay bricks on measuring clay. We use high-density kaolin or basalt wool. We twist a cylinder from a sheet of wool in several layers to avoid seams - heat loss bridges. Fasten to the walls with asbestos cord and ceramic buttons. The edges of the top of the insulation are folded outward, this will seal and heat-insulate the joints of the lid and the body.

- We lay the roof covering on the posts.

Important! The roof is not fitted tightly to the walls, but through the cracks hot air must penetrateThe flame does not come into contact with the items being fired.

If the product is heavy, we use dry masonry made of fireclay bricks for the ceiling; if it is light, we use porcelain stoneware tiles of the appropriate size.

- We install the burner. It can be purchased in gas equipment stores. It is better to choose the power not less than 2 kilowatts (depends on heat loss and volume of the structure).

- We drill a hole for the burner at the bottom of the body and lining. The flame should not touch the products, this is the main principle of the nozzle placement. When the nozzle is installed horizontally, adjustment and maintenance are easier.

- We insulate the structure's cover. To minimize heat loss, we insulate the entire structure from the outside.

- We leave an opening in the lid to allow combustion products to escape and control the process. We provide a valve for temperature regulation.

- To measure the temperature inside the oven, we install a thermocouple of an electronic thermometer.

The stove is ready. A test run is carried out. If fireclay bricks were used, the stove is first dried in a gentle mode.

Difficulties in manufacturing

Please note:

-

Safe connection of the cylinder to the burner. Do not use a rubber gas hose near a hot stove - use a metal one.

The gas cylinder must be kept at a safe distance and we must use a reducer with a check valve.

- Seal all cracks using clay, asbestos or basalt cord.

- Bake installed away from flammable objects.

- At work Do not touch the oven components with bare hands.

Attention! Don't let children onto the playground!

- The outlet for the burnt gases must be of sufficient diameter., otherwise the flame will “choke”, you can regulate it with a piece of insulation.

Useful video

The video presents an overview of the homemade stove and its first use.

What is better: to make yourself or to buy?

A homemade ceramic kiln is quite can compete with factory productsIf you select burners with different power, then by changing the flame intensity, you achieve the desired temperature.

Factory models are calculated by engineers and use fuel more economically, but for firing in a craft workshop, a homemade oven is quite sufficient.

If you have the tools and time, a home craftsman can inexpensively obtain a furnace with the required parameters.

Achieve an acceptable temperature at 900 °C It is quite possible in such a furnace. It is used both for drying products and for rough firing of simple ceramics.

If the goal is to get earthenware or porcelain, a higher temperature with precise regulation will be required. A homemade furnace will not work for this; a factory-made muffle or electric furnace will be required.

Comments