Tins and other scrap - for secondary raw materials! How to make a furnace for melting aluminum with your own hands

Aluminum alloys have low melting point and good workability parts. And there is always a lot of aluminum scrap on hand.

That's why aluminum is often melted. at home to replace non-standard or small parts of mechanisms: a blank is cast and then processed on a lathe. Sometimes souvenirs and small interior items are made from aluminum with your own hands.

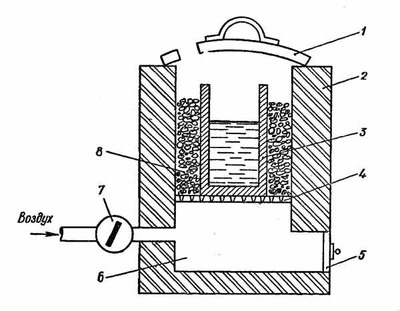

The device of the melting furnace

Homemade furnaces for melting aluminum consist of a body - metal cylinder (2), lined with refractory (fireclay with sand or concrete). Inside the shaft there is charcoal (8), which serves as fuel. It is installed in crucible (3) — a container in which the metal will be melted. The crucible can be a thick tin can, a teapot, or any stainless steel container.

At the bottom of the shaft (6) made air injection hole (7) through lattice base (4), which allows you to maintain combustion and regulate the temperature in the oven.

A hair dryer or vacuum cleaner pipe is used as a blower. Damper (5) necessary to remove excess air.

For furnaces with a capacity of several tens of kilograms, it is necessary cover (1) for quick and uniform heating of metal. In small furnaces it is possible to do without it.

Furnace Elements should not deform or melt when heated. Therefore, the use of aluminum housings, tubes and crucibles is unacceptable. It is best to take for the construction of the structure steel or cast iron details.

Reference. It is also used as fuel for smelting aluminum. natural gas or electricity.

How to make a furnace for melting metal?

Creating a small unit that can melt several kilograms of aluminum scrap is not a difficult task. To lay out a furnace on a garden plot, you will need the following materials:

- red bricks - 20-25 pcs.;

- high tin can - 1 pc.;

- grill grate - 1 pc.;

- drying hair dryer - 1 pc.;

- piece of pipe, the diameter of which matches the outlet of the hair dryer - 1 pc.;

- roll of duct tape;

- segment steel wire length 30-50 cm;

- coal for ignition (the amount depends on how much aluminum needs to be melted).

The bricks will be both body and fireproof coating oven, a tin can will serve as a crucible. At the top of the can are being made two holes opposite each other, and through them the wire is threaded through. It will be possible to lift and pull the crucible with the melt out of the furnace. Air will be supplied from a hair dryer turned on in the cold air mode. It is necessary to tape or insulate the outlet of the hair dryer tie a piece of pipe - this will be the air duct.

Such simple scheme The oven is convenient because you don’t actually need any tools to create it; everything is done by hand.

Important! Do not use elements with zinc coating, since when melting aluminum, toxic zinc vapors will be released.

Brick well installation plan

- It is being laid out one row bricks in the form of a rectangular wellThe internal dimensions of the hole should be approximately the length and width of one brick. On one side two bricks are laid out so as to form a corridor for the air duct. The width of the corridor is equal to tube diameter for air supply.

- On the laid out row the grille is being installedInstead of a grill grate, you can use any metal lid or plate with holes for air supply.

- It is placed on the grill second row bricks, without any gap for the air duct.

Photo 1. The finished brick well for the smelting furnace. The edges are reinforced with metal strips, the air duct opening is visible.

- It is being created air duct. To the hair dryer with tape or electrical tape a piece of pipe is attached. To ensure the strength of the structure, the connection point wrapped in thick paper, and then connects with adhesive tape. Electrical tape is a more elastic material compared to scotch tape, so it is more convenient to work with. Also, the cold air button on the hair dryer is fixed with scotch tape. Ready the mechanism is brought to the bottom row bricks.

- Into the stove well on the grate coal is poured and melted for ignition. The hair dryer is turned on, which activates the combustion process.

Advice. The air flow intensity can be adjusted by changing hair dryer operating mode, and also distance between pipe and window for the air duct.

- Tin is being installed to the top row bricks by the wire threaded through it. Like a pot over a fire, it hangs over the grate.

- After the furnace has been fired up and the crucible has been installed third row are put two more bricks so that from a rectangular hole you get a square one. This will fix the can inside the body and heat up the oven space faster.

After heating the jar, add it scrap can be loaded for remelting. A sign that the can is warmed up is its reddening.

Important! Melting aluminum is recommended in a heated crucibleWhen loading cold scrap into a cold can, there is a greater chance that the can will burn out and the aluminum will flow out of the can directly onto the coal.

The principle of the device and operation of such a furnace is very simple and does not cause difficulties. However, it is always worth remembering safety precautions:

- work with fire-resistant gloves;

- avoid getting water into the melt;

- Do not use materials containing toxic substances.

Two-can construction

Another type of homemade furnace for melting aluminum is a design made of two large jarsOne of them serves body, in which a hole is cut for air supply, and bottom of the second jars with holes serves as a divider.

A crucible is placed inside the jars.

Such a device very compact, and small volumes of metal can be melted even in a ventilated garage. However, the design is not distinguished by its stability and fire resistance, and will only last a few cycles.

Possible problems and their solutions

A carelessly assembled device causes the stove to operate inefficiently and makes it dangerous to use. Here are a few things to consider:

- Gaps and cracks in a brick case. They can be formed by chips in the bricks or loose fit of the refractories to each other. Gaps reduce the efficiency of the fuel, reduce the intensity and temperature of combustion. Aluminum in the crucible may simply not melt.

Therefore, after laying out each row, a visual check is carried out for holes. Holes are sealed with a sand-clay mixture or covered with fireproof material.

Concrete mortar is recommended to be used only in the case of a stationary unit that is not planned to be dismantled. But asbestos sheets and chips should not be used in places where the oven is heated, since this material is a carcinogen.

- Violation of horizontal level buildings. The skew reduces the stability of the structure and creates conditions for uneven distribution of coal. As a result, uneven heating of the crucible and the metal in it.

Laying out each row of bricks, especially the bottom row controlled by level. You can also check the horizontality, placing a jar of water on the grillOn a flat surface, the top edge of the water will be parallel to the edge of the jar.

Useful video

Check out this video on how to make an aluminum smelter.

DIY Aluminum Furnace - Easy!

The desire to have a small smelting furnace at home is easily realized, does not require large investments, knowledge and time for construction. You can build the unit yourself capacity up to 10 kg molten metal and make souvenirs, fittings or blanks for small aluminum parts. The temperature reached in a home furnace allows melting most aluminum alloys in a short time (several tens of minutes depending on the volume of scrap).

Of course, the quality of the resulting metal differs from industrialAluminum melted at home contains an increased amount of oxide films, contaminants, and is less stable in chemical composition. But it will still be useful. for household use.

Comments

The downside is that cast iron gets hot both from the outside and from the inside, you need special grips to touch it. I also recommend making a lid on top and a small hole on the side.