It is necessary to monitor the indicators! What should be the pressure in the heating expansion tank

The expansion tank performs two tasks: compensation for the increase in liquid volume during heating and protection against water hammer.

To prevent breakdowns of heating systems, such devices are necessarily installed in them.

What air pressure should be in the expansion tank of the heating system

The empty capacity of the air chamber at room temperature. It should be equal to the static value in a tank filled with water. In this position, the membrane is in equilibrium, and the gas pressure is compensated by the liquid pressure. For every 10 meters of pressure order is required 1 atm. Despite this, for the normal operation of the entire system it is sufficient to create the indicator specified in the device passport.

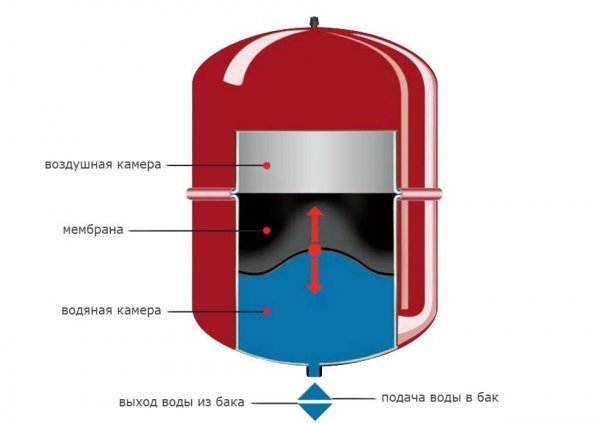

Photo 1. Diagram of the expansion tank for closed-type heating systems. The arrows indicate the parts of the product.

Most expansion tanks require sufficient pressure to operate properly. 0.9 atm. This is due to the pressure that the membrane creates during operation. Its average value is 1.2 atm. Both values fluctuate within a small range with a maximum deviation 0.1.

If the heating system is not made according to classical schemes, separate calculations are carried out for it: The volume of the coolant, tank, efficiency factor and initial charging pressure are determined. To do this, you should invite a specialist who will take into account other minor factors.

How to check the indicators

The easiest way to take a measurement is to attach a pressure gauge. The problem arises at the preparation stage, since most tanks do not have space for fastening. At the same time, the device should have a nipple to which the compressor with the sensor can be easily connected.

Reference. It is not difficult to translate the dimensions of values: 1 Bar = 1 atm = 0.1 MPa.

How to adjust the hot water pressure in the system

Water pressure is a fairly easy parameter to adjust. To do this you will need:

- Make a calculation. After completing it, subtract from the obtained value 0.2 atm.

- Before installation bleed (or pump) air out of the system to the desired level.

- Connect the container to the pipeline and fill it with liquid. The process is done slowly so as not to miss the moment of establishing normal pressure.

- Connect the pump and pump in the liquid until operating pressure is reached.

- The first time the device is turned on, the water is heated to its maximum.In this case, the volume of liquid will increase to a value that takes into account the specific increment.

To make adjustments using a car pressure gauge, you need to:

- Turn off the heater and wait 7-10 minutes until the system stops.

- Tighten the shut-off elements and drain the working water. If the membrane is built into the boiler, close the supply and return lines.

- Attach the pump to the nipple.

- Pump up one and a half atmospheres, release the remaining liquid, then the air.

- Close all valves, create the necessary pressure.

- Remove the pump, open the valve, pour in water.

Setting up the parameters in a new membrane expansion tank

The device is divided into two parts, separated by a membrane. It puts pressure on one of the halves., this is taken into account during setup.

Most devices have factory settings that are not always suitable for use in certain conditions.

To change the indicators, a nipple is provided, to which the plumber connects a compressor or a hand pump.

Attention! Many pressure gauges show excess. To determine the actual pressure, add 1 atm.

The initial value is made equal to that obtained in a cold system by adding 0.2 atm. The sum is the value of the static pressure divided by by 10For example, in a house of height 8 m:

P = 8/10 + 0.2 atm.

The values are achieved by filling the container with air. through the valve.

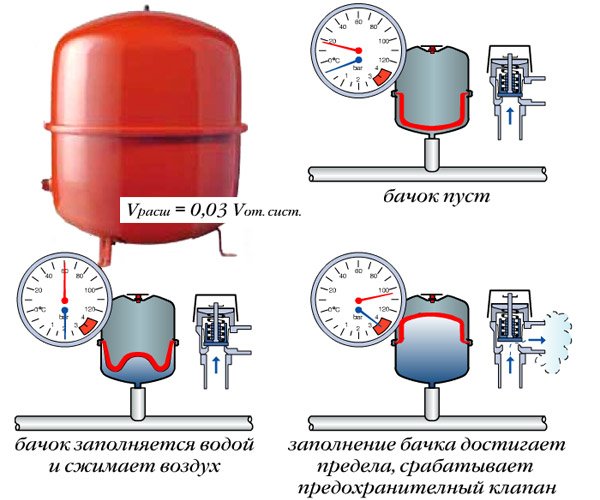

Incorrect calculations can lead to one of two problems:

- Overflow of the tank. Sometimes the air cavity is set to a value twice the static pressure. Turning on the pump will change the number, but not more than at 1 atm. If the difference is greater, there will be a shortage, which will cause the compensator to start pushing the coolant out of the tank. This can lead to a serious accident.

Photo 2. Pressure standards in the expansion tank: when it is empty, when it is filled with water, and when the filling of the device reaches the limit.

- Obtaining an insufficient indicator. In a filled system, the working fluid will push through the membrane and fill the entire volume. Each time the heater is turned on or the pressure increases, the fuse may trip. The expander will become useless in such a situation.

Important! The initial setup must be done correctly to avoid problems. But even after a good technician has done the job, fuses may start to trip. This is usually due to with insufficient expansion tank capacity.

The solution will require purchasing a new device. It must accommodate not less than 10% of the volume of the entire harness.

Why does pressure drop?

The indicator should be constant, but in some cases there are problems with deviation. The value decreases:

- If a leak occurs. They rarely occur in water-filled systems. Other liquids encourage the formation and expansion of small cracks that cause the problem.

- In case of boiler malfunctions. If there is no leak, but the pressure drops, you should call a specialist. He will help determine the fault and recommend a solution.

Useful video

Watch the video to learn where in the system the expansion tanks should be installed.

Maintenance

Regular monitoring of the equipment condition will help to avoid problems during the heating season. It is recommended to carry out work to detect faults twice a year: before and after the end of winter. To do this, you should invite a specialist who will carefully check the system.