Automatic or manual: how to decide on heating system refill?

The heating system is fed with to reduce water loss in the harness. The device consists of several components that interact with each other. Most devices operate automatically, although manual ones are also widespread.

Content

Boiler heating system feed from the water supply: what is it?

The use of the harness leads to reduction of the amount of coolant in it. The free space is filled with air, creating traffic jams. As a result, the equipment overheats, which causes breakdowns.

Water is lost in the following situations:

- In an open circuit, the liquid evaporates in the expansion tank.

- The air vent also removes water vapor.

- When the overheating protection mechanism is triggered, the coolant is discharged.

- There are some invisible cracks in the binding.

- The pipes become covered with scale or rust.

To avoid problems, they use heating feed from the water supply. In most cases, it works autonomously, measuring the current volume of water and replenishing the deficiency. In this way, the standard pressure of the system is restored. For this, cold water supply or special liquid, stored in a storage tank.

How to do it: feed or return diagram

The process is running in one of two ways:

- Manual adjustment is done in small systems, since pressure changes in them are smaller. The latter are determined by a pressure gauge. Having detected a deviation from the norm, open the feed valve and wait for the value to be restored.

- Automatic installation processes data independently and takes steps to eliminate the problems.

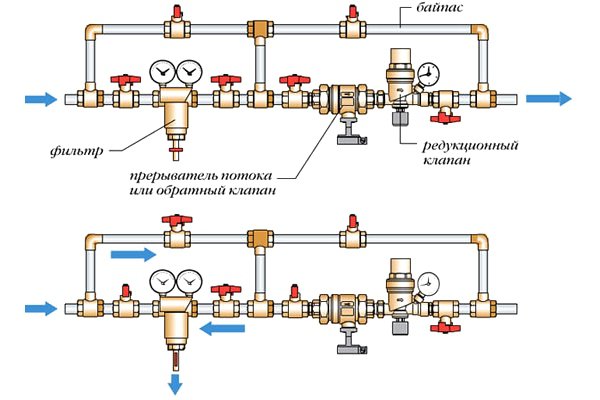

Photo 1. Scheme of automatic installation of the heating system feed station, data is processed automatically.

The difference lies in no need to monitor readings, but due to the constant operation of the device, the power consumption increases.

Important! Replenishment is not required constantly, but the equipment does not need to be idle. The device can be used to fill empty coolant piping, carry out pressure testing or flush the pipes.

Elements of the device

The feed system consists of five interconnected parts.

Actuator

Component structure depends on the control method. In manual, one valve is used to change the water supply. In automatic, several control devices are placed.

The most classic option is two valves (shut-off and check) and a reducer. They are used in both mechanical and electronic systems.

The equipment with control devices also depends depending on the type of heating.

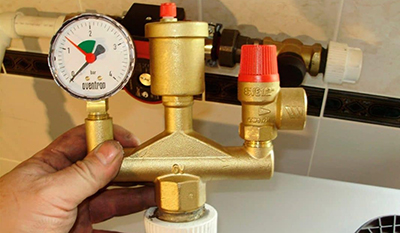

The actuator must be adjusted. The minimum pressure level is set in it using a valve installed in the upper part. Having selected the required threshold, the position is fixed with a lock nut. Correct adjustment is facilitated by meter, built into the mechanism.

Having noticed a malfunction in the heating, the membrane releases the spring, which pushes the rod. The latter changes the size of the hole that lets water into the piping. Normalization of pressure returns the components to their original position.

Check valve

Serves to separate water and heating liquids. Otherwise there is a risk:

- bacterial infections;

- spread of corrosion from the piping into cold or hot water supply;

Photo 2. Watts Alimat ALMD 1/2 BP check valve with pressure gauge, necessary for separating heating liquid from tap water.

- reduction in boiler efficiency due to increased load and pressure loss.

Attention! The higher the pressure in the cold water supply pipes, the greater the chance of coolant getting into the water supplyThis is also affected by a violation of the position or capacity of the shut-off valves.

Check valve helps to avoid such problems. It is mounted in the rear part of the actuator. Some feed systems include throttle. It is installed in the reducer. Modern devices are supplied with interrupters mounted in front of the valve.

Reducer at the boiler

The reducer is used to turn on the feed into the piping. It is placed on the boiler return pipe. Due to the low pressure, the coolant easily enters the system.

If the project provides for the installation of a circulation pump, then the latter is installed second.

Otherwise it is possible occurrence of malfunctions, leading to disruption of the entire heating system.

Accumulator, manual and automatic pump

During the operation of a water heating system, there comes a point when the pressure exceeds the normal level. This occurs when liquid is lost and the space is filled with air. To restore normal operation, a pump is used that compensates for the deficiency using cold water supply.

Some devices include storage tank, in which, if necessary, the coolant is stored. Such mechanisms allow you to fix the problem with pressure in the entire piping, including cold water supply.

Pumps are divided into two types:

- Manual ones require placement above the expansion tank. This is called gravity montage.

- Automatic ones use hydraulic accumulators connected to the membrane. The connection is kept under pressure.

But there are also vertical devices that do not include a storage tank. They are placed in a well with water.

Photo 3. Automatic Grundfos pump in a heating make-up system with a hydraulic accumulator, connected to the membrane.

Water filters

Necessary to protect the device from dirt and impurities coming with cold water. Used two types:

- The first ones are needed to remove debris.They are placed in the actuator to prevent dirt particles from entering the system.

- The second ones carry out chemical cleaning of the liquid., decomposing solid salt particles.

Both types need to be checked periodically for functionality and degree of contamination.

Calculation of water consumption in the feed station

It is a generalized name for the entire system.

They include the listed parts and are ready for use immediately after installation.

The stations also have built-in pump. Most devices operate in automatic mode, which determines the high cost.

The average price of the unit is 25 thousand rubles.

In an open system

Such a harness usually has a built-in expansion tank, mounted in the upper part of the main pipe. It monitors the water temperature, changing the volume when the pressure fluctuates. To determine the level of the coolant, a control tube is brought out of the device. At the extreme point of the latter, a shut-off valvesIn such designs, protection is obtained against water leakage that exceeds the average flow rate.

Reference! Periodically, at a specified control time, the valve must be opened. After checking the presence of water, it is closed. If a deficiency is detected, the amount of coolant is replenished.

The system feed includes three components:

- ball valve, serving to move technical fluid from water supply to heating;

- filters to protect against dirt particles, bacteria and salts;

- check valve, preventing the coolant from entering the drinking water tap.

To calculate the system, it is necessary to calculate the average DHW consumption with a coefficient of 1.2. It is being increased by 0.75% the actual capacity of pipelines and all adjacent components.

If the plots are located more than 5 km from the energy source, then the calculated liquid consumption increases by 0.5%.

Closed type

In these closed systems, as opposed to open ones, the harness is always under high pressure. This is due to the difficulty of manually adjusting the liquid level. Therefore, actuators are used with automatic control.

When they detect a loss of water, they replenish it. Although such replenishment works independently, periodically it is necessary to check the condition of filters and valves. It is also necessary to install a pressure gauge to display the actual pressure during testing.

To calculate, calculate the actual capacity of the entire water supply and find 0.75% from the obtained indicator. Similar to open systems, for areas located more than 5 km, the result is reduced up to 0.5%.

Installation

The installation of the feed is possible after performing the following steps:

- The place with the lowest pressure is found in the harness. Typically this point is located near the pump unit.

- To prevent liquids from mixing, buy additional reinforcement.

- To protect against overflow, a second pump is purchased.

When choosing a device, you should focus on the size of the building. For small apartments or houses, a simple feed with a feed or return with a small adhesion coefficient is sufficient. Such devices are protected from scale, which increases the service life.

The installation looks like this:

- To the point of minimum strapping pressure they put in a valve.

- For mechanical systems use a crane, which is placed between the cold water supply and heating.

- After testing installing a booster pump, if pressure is detected to be higher than normal.

- To protect the feed from water they install shut-off valves.

- Connect the pressure gauge.

Antifreeze

To fill the system with such a substance, it is necessary to manually pour the liquid from a bucket or canister into the drain valve. The latter is placed on any pipe as a tee or instead of a plug.

To fill, connect the submersible pump to the valve, lowering the other end into a container with antifreeze. Then clean the system of air.

The pressure in the harness is increased up to one and a half atmospheres, gradually reducing to one. The process is repeated until the desired indicator is obtained, which is monitored on the pressure gauge.

Useful video

Watch the video for advice from a specialist explaining how and with what the heating system is filled.

Cleaning the device

To remove excess substances it is necessary:

- Make insulation.

- Unscrew the control element.

- Remove the screw, then remove the cover.

- Replace the cartridge.

- Assemble the device and reconfigure it.

Filters are cleaned separately. Mechanical, depending on the degree of contamination, scrub with a metal brush using household detergents. Chemical, in most cases, it is necessary to replace.