What is this unusual device for? Heating bypass: what is it, installation of the device

A bypass (shunt) for a heating system is a pipeline element that mounted parallel to the radiator or circulation pump (CP) to pass the heat carrier (HP) bypassing the heating device.

Content

Description

It is produced in two versions:

- In the form of a jumper made of a pipe that connects the supply and return lines in front of the heating device.

- As an element of the connection unit for radiators with bottom connection, made in one housing with the supply and outlet pipes.

Additionally, it can be equipped with shut-off and control valves:

- ball valve for shut-off;

- three-way valve for distributing the flow of heat pump between the shunt and the battery;

- a check valve for passing the heat pump through the shunt in only one direction.

The device is intended:

- to maintain the general circulation of the coolant in the event of failure of the battery or central heating unit;

- to regulate the flow of heat pumps through the battery and shunt (to balance the thermal regime).

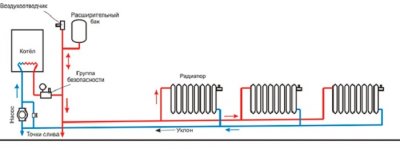

Application in batteries with a single-pipe system

In such a system, all heating devices are mounted in series: the output of one battery is connected to the input of another. The one-pipe system has a number of disadvantages:

- The TN approaches the last battery in the chain already cooled.

- If one battery fails, the circulation of the TN stops.

To eliminate these shortcomings, a single-pipe the system is equipped with shunt jumpers connecting the supply and return lines:

- A portion of the heated heat pump, which has passed through the jumpers, approaches the last batteries.

- When the battery fails or is disconnected by shut-off valves, the heat pump circulates bypassing the jumper.

Application in two-pipe system

In a two-pipe system, all batteries connected in parallel to the supply and return risers.

The failure of one radiator does not affect the performance of others, therefore bypass is not used in a two-pipe system: its installation parallel to the heating device is equivalent to a jumper between the supply and return, which worsens circulation and temperature conditions.

Types of bypasses

There are several types of bypasses for use in heating systems.

Unregulated

In progress in the form of a shunt jumper-bypassThere is no shut-off and control valve (tap or check valve) on the jumper.

Operating principle

- The portion of the hot heat pump that has passed through the bypass is mixed with the flow at the battery outlet and increases the temperature of the heating system, entering the input of the next battery.

- When the heating device fails, the flow of heat pump bypasses the battery, maintaining circulation.

Peculiarities

- With vertical wiring the bypass diameter is one step smaller than the diameter of the supply pipes.

- For horizontal wiring the bypass diameter coincides with the feed pipe, and the diameter of the branches up the battery is one step smaller (the heated heat pump tends to rise).

- They are installing as close to the battery as possible (near the shut-off valves).

Manually controlled: what is it?

For manual regulation of the flow of the heat pump through the bypass, it is installed or a ball valve to shut off, or a three-way valve at the intersection of the bypass and the supply pipe to the radiator.

Operating principle

The three-way valve has three positions:

- closes the bypass and directs the entire flow of heat pump into the radiator;

- closes the supply to the radiator and opens the bypass for the flow of the heat pump (position for repair or replacement of the radiator);

- opens both paths for the TN: to the battery and along the bypass.

Peculiarities

- The tap on the bypass next to the battery are usually installed to block the jumper when the radiator is not heating well. But such a solution is technically illiterate - the flow through the bypass is approximately equal to the flow through one section of the radiator, so there will be no significant increase in the battery temperature.

- In a private house there is a ball valve installed in parallel with the central pump on the return pipe. The valve is closed when the pump is running and is opened manually when the pump fails or when it is replaced to restore circulation.

Attention! In an apartment building with a one-pipe system, a valve on the radiator bypass installation is prohibited. It can lead to a disruption of circulation and a lower temperature of the coolant supplied to neighboring apartments.

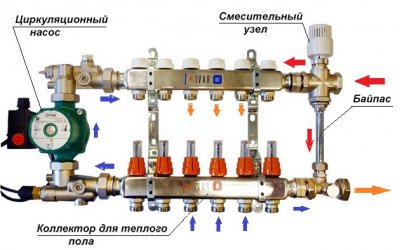

Automatic, how does it work with a pump

It is being installed in parallel with the central nervous systemA check valve is mounted on the shunt pipe to automatically restore circulation through the bypass when the central pump is stopped.

Operating principle

Bypass with differential (ball) valve installed in parallel with the central heating system on the vertical pipe supplying the coolant from the boiler.

When the pump is operating, part of the flow presses the rubber ball against the funnel and closes the passage of the heat pump through the shunt pipeline.

When the pump is switched off, the ball rises under the pressure of the heat pump flow along the supply pipe and opens the passage for the heat pump through the bypass.

Bypass with petal check valve are installed parallel to the pump on a horizontal return pipe (in a gravity system). The valve shutter (petal) is pressed against the seal by the flow from the pump, closing the bypass. When the pump stops, the petal moves away from the seal (opens) under the hydraulic pressure of the return, restoring circulation.

Important! Required periodically check the functionality of the check valveso that it does not become clogged with deposits and dirt.

The check valve is usually mounted on the main pipe (supply or return). Branches from the main pipe to the central heating system are made two sizes smaller in diameter.

Use cases

Bypasses have several purposes.

Adjusting the temperature in the radiator

To regulate the temperature in a system with a bypass to the heating device (after the shut-off valve) install elements:

- Regulating valve for manual temperature change. When you turn the handle, the area of the passage hole in the valve changes. Accordingly, the amount of heat pump supplied to the heating device and its temperature change.

- Valve with thermal head for automatic temperature change. The regulator sets the position corresponding to the desired temperature. To increase the temperature, the valve is moved to the "open" position, and allows the heat pump to heat the heating device. Otherwise, the valve is moved to the "closed" position, so that the heating device cools down.

Both elements regulate the flow of coolant through the heating device, directing its excess around the radiator through a shunt jumper.

Work without power supply

If the gravity heating system is equipped with a central heating system with a bypass, then when the power goes out TN circulation continues through the bypass. With a check valve on the bypass, this happens automatically; the ball valve must be opened manually.

Attention! If the ball valve is not opened in time when the pump stops (while the solid fuel boiler is running), this may lead to to disruption of circulation and damage to boiler equipment.

Therefore, an uninterruptible power supply with an autonomous operating time of 5-10 minutesThis is enough time to open the tap after the power supply is cut off.

Improving the one-pipe system

For a comprehensive modernization of a single-pipe system apply technical solutions:

- Each radiator is equipped in the house bypass jumper and valve with a thermal head for uniform heating of all heating devices.

- Each riser after the last battery equip with a special thermostatic regulator with a remote temperature sensor. When the regulators on the batteries along the riser are closed, the return temperature is higher than the calculated one. In order not to waste heated HP, the thermostatic regulator closes the riser. This allows you to balance all the risers in the house according to the HP consumption depending on the temperature.

As a result of the comprehensive modernization, the real TN consumption may decrease from 500 liters per hour to 100 liters per hour while maintaining a comfortable temperature.

Selecting a bypass for heating

- Radiator in a one-pipe system It is recommended to bypass with a jumper in the form of a section of pipe between the inlet and outlet to the radiator.

- CN, installed vertically to the feed from the boiler, is bypassed by an automatic bypass with a differential (ball) valve on the feed pipe. The main manufacturer of differential valves is Invena (Poland).

- CN, installed horizontally on the return line, they are shunted by a bypass with a ball valve or with a non-return petal valve.

Approximate cost

Approximate price of the device elements:

- differential (ball) valve 1+14" Invena ZZ-10-025 — 500 rub;

- Itap horizontal reed valve 1+14" — 825 rub;

- ball valve 1+14" — 950 rub.

How to do the installation yourself

The materials required are:

- drive 1+14" 200 mm complete with coupling and lock nut — 1 pc.;

- threaded bends 34" — 2 pcs.;

- ball valve 34" — 2 pcs.;

- sump 34" — 1 pc.;

- corners 34" — 2 pcs.;

- circulation pump 34"— 1 pc.;

- ball valve 1+14" — 1 pc.;

Installation process:

- Assemble the central heating system piping (pump, elbows, taps, mud collector, threaded elbows).

- Cut split into two halves approximately in the middle of the central section (without threads).

- Connect both halves to the tap 1+14".

- Mark and make holes on the halves of the coupling for the bends 34" to the Central Neighborhood.

- Disassemble the assembled CN piping.

- Weld the bends 34" to the halves of the coupling.

- Finally assemble the CN piping with sealing of threaded connections.

- Adjust the coupling of the coupling to set a distance sufficient for installing the pump with gaskets (do not install the pump itself). Pack the coupling and lock it with a lock nut.

- Cut a section out of the return pipe (for welding the bypass).

- Weld the assembled bypass to the section of the return pipe.

- Install the central heating system.

Do you need a check valve?

The valve is needed when installing a shunt jumper with a central heating system. in a gravity heating system to automatically start natural circulation when the central heating system is turned off.

Is it possible to install a crane?

A crane is needed when installing a shunt unit with a central heating element on the return pipe for manual start of circulation when the central pump stops.

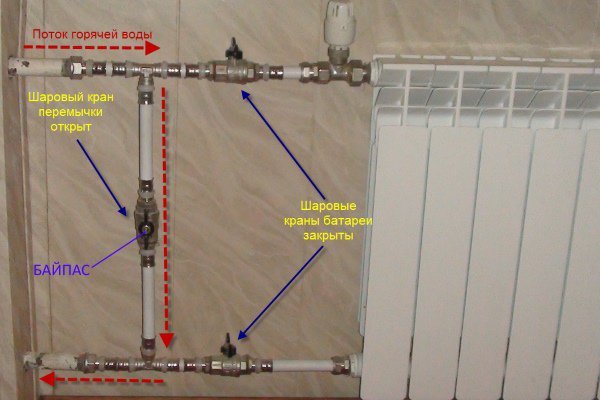

Photos of finished structures

Photo 1. Bypass in the form of a jumper, connecting the supply and return. Ball valves are also used in the design.

Photo 2. Bypass installed on the heating system pipe. The design uses a ball valve.

Photo 3. Bypass in the form of a jumper, installed on a cast-iron heating radiator. Design without valves and taps.

Useful video

Watch the video, which demonstrates the process of assembling a polypropylene bypass for a heating system.

Conclusion

The bypass in the heating system is a critical unit on which it depends operation and safety of the entire heating system. Installation of such a unit is a technologically complex task that is best left to specialists.

Comments